Diagnostics and Troubleshooting

XPR300 Instruction Manual 809480 333

2. Make sure that the gas inlet pressures inside the torch connect console are acceptable:

3. Use the regulators to increase or decrease the inlet pressure.

4. If the pressure remains too low, examine gas hoses and gas inlet fittings. Look for:

Damage or kinks that can restrict flow.

Leaks that can decrease pressure.

5. Replace the hoses if you find damage or kinks.

6. Reposition the hoses if you find fixable kinks.

7. Replace any fitting that has damage.

8. Tighten loose connections if found.

9. If you cannot find or resolve the problem with these corrective actions, contact your cutting

machine supplier or regional Hypertherm Technical Service team.

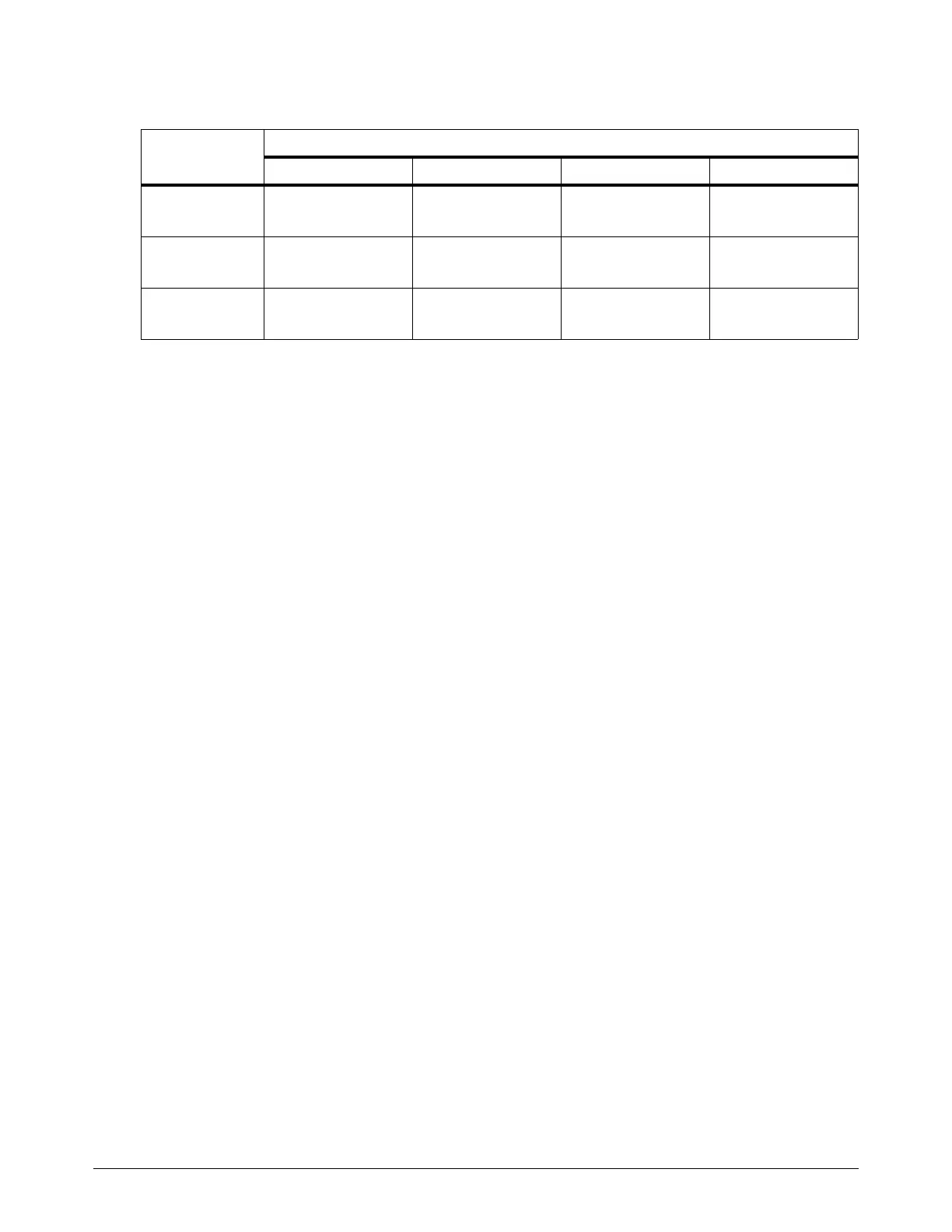

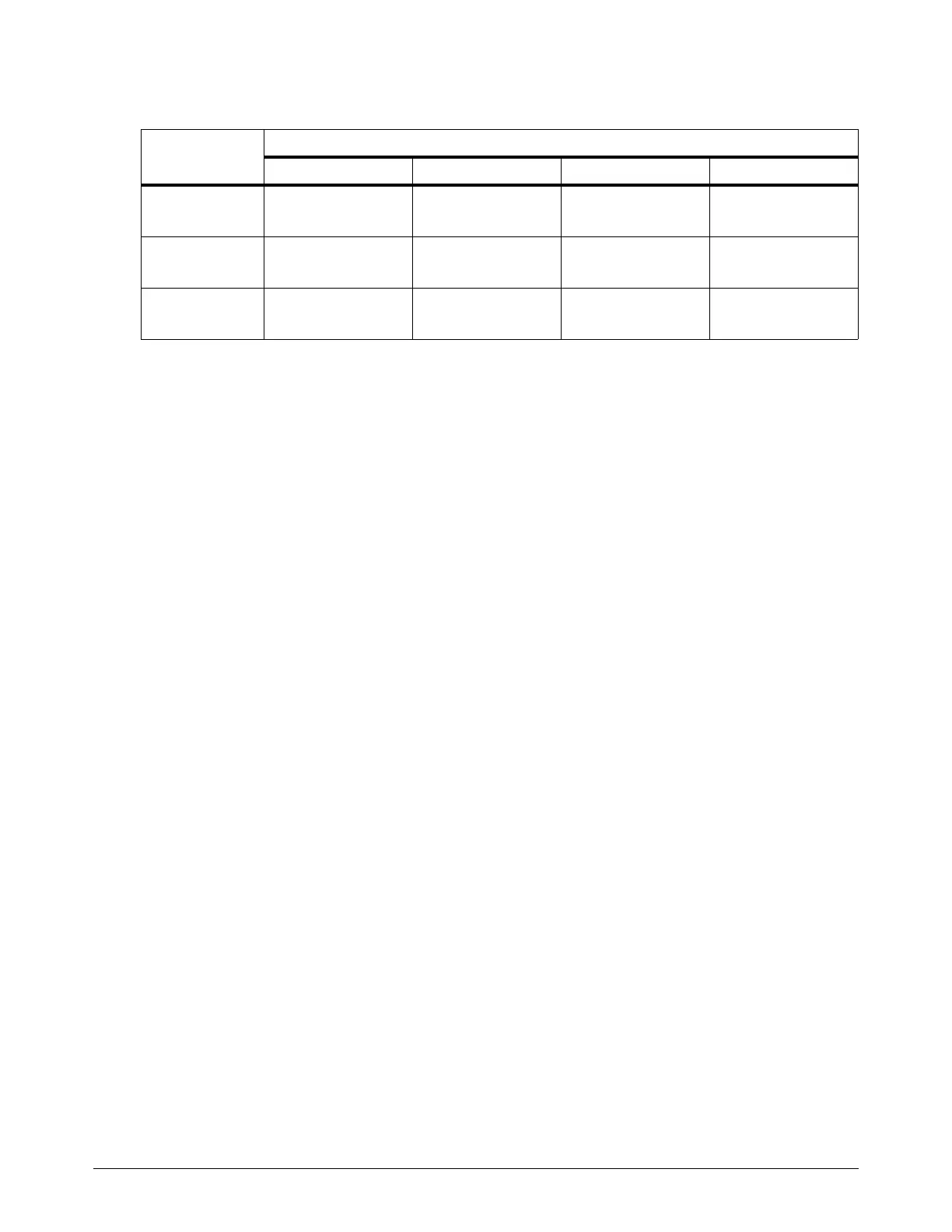

Gas connect

console

Acceptable gas inlet pressures in the torch connect console

N

2

O

2

Air Ar

Core

7.5 bar ± 0.4

(110 psi ± 5)

7.5 bar ± 0.4

(110 psi ± 5)

7.5 bar ± 0.4

(110 psi ± 5)

–

VWI

7.5 bar ± 0.4

(110 psi ± 5)

7.5 bar ± 0.4

(110 psi ± 5)

7.5 bar ± 0.4

(110 psi ± 5)

7.5 bar ± 0.4

(110 psi ± 5)

OptiMix

8.3 bar ± 0.4

(100 psi ± 5)

8.3 bar ± 0.4

(115 psi ± 5)

7.9 bar ± 0.4

(115 psi ± 5)

8.3 bar ± 0.4

(100 psi ± 5)

Loading...

Loading...