Diagnostics and Troubleshooting

XPR300 Instruction Manual 809480 341

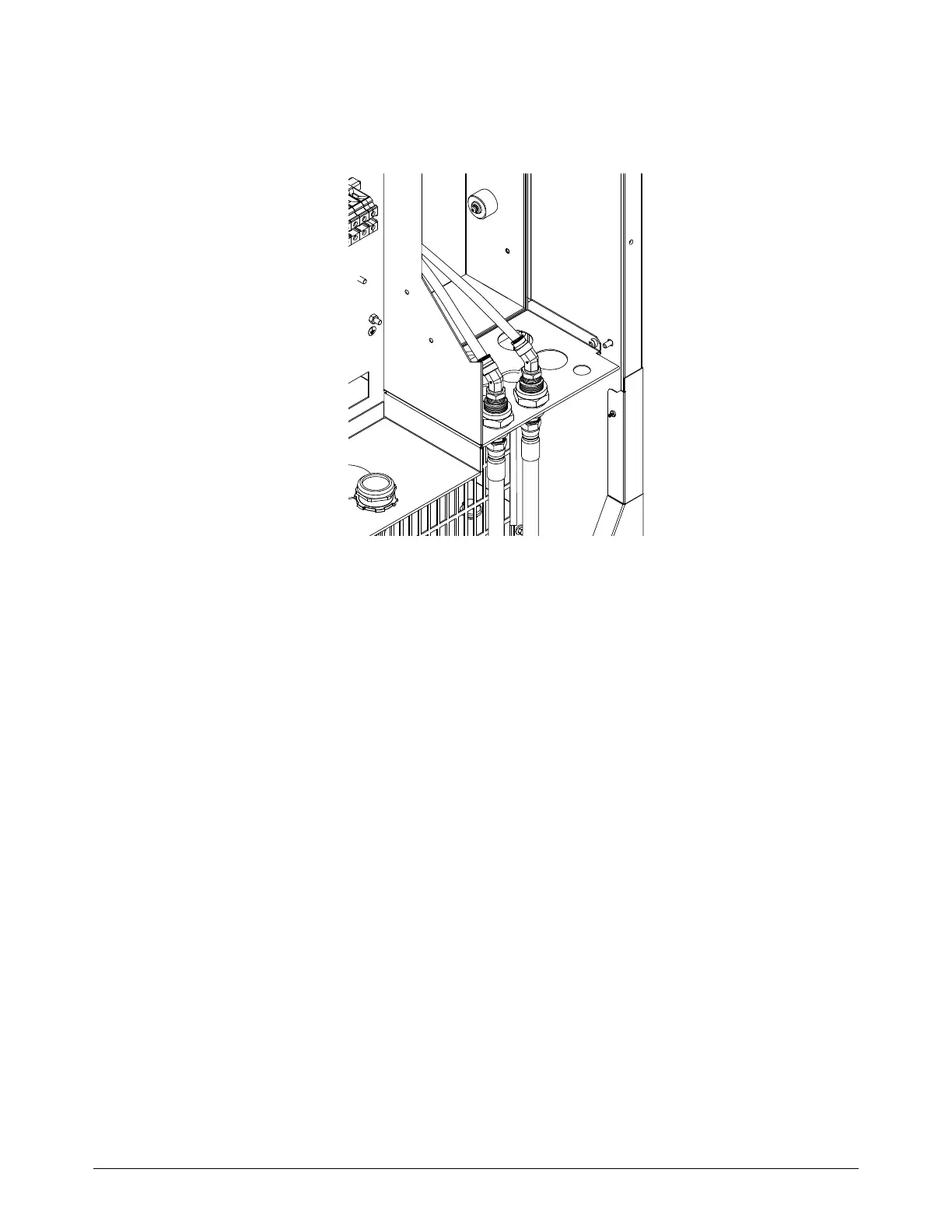

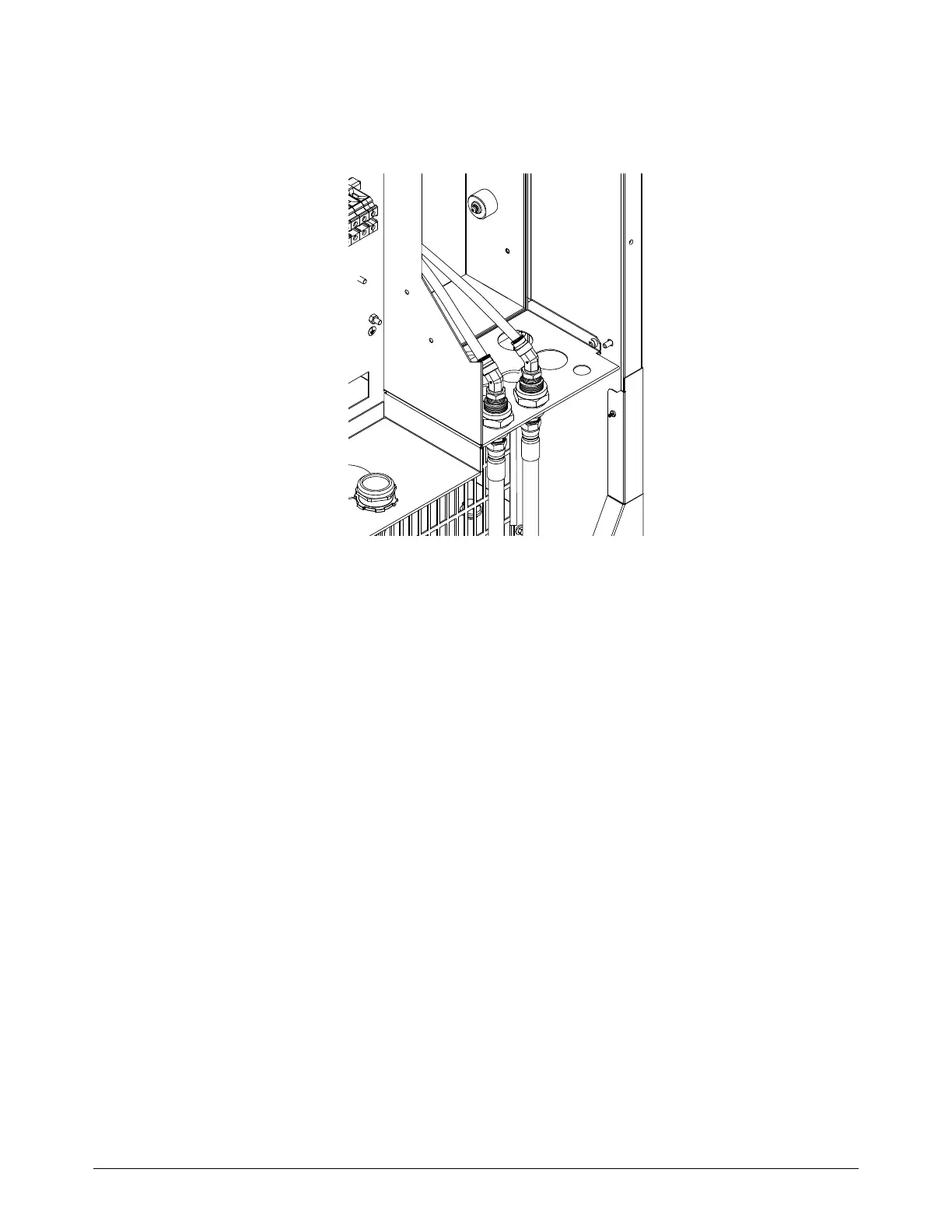

3. Disconnect the coolant return hose (red) from the coolant return fitting (red) inside the rear of

the plasma power supply. Use the container to catch coolant leaks if needed, but empty it

before you start the test

4. Put the end of the coolant return hose into the container.

5. Restore electrical power to the cutting system.

6. Send a process to the cutting system.

7. When you hear the coolant pump turn ON, begin a 30-second count while coolant flows into

the container.

8. After 30 seconds look at the amount of coolant in the container. It should be at least 1.89 liters

(0.5 US gallon).

9. If the flow rate is outside of the correct range, an internal obstruction or leak can be the cause.

10. If you find obstructions, remove them. Replace damaged parts if found.

11 . If coolant flow remains slow, and it has been more than 6 months since the last coolant

replacement, replace the coolant. Refer to Replace all of the coolant on page 254.

Hypertherm recommends coolant replacement every 6 months. For

complete preventive maintenance information, refer to the XPR Preventive

Maintenance Program (PMP) Instruction Manual (809490).

12. If coolant flow remains slow after replacement, verify that the following function and components

are good:

Bypass is working

Coolant pump motor

Loading...

Loading...