Industrial Sewing Machine SADE

117

Regularly (at least once a year) check the condition of electrical wiring and other electri-

cal components. When you notice any damage in the protective coating replace the wire

with a new one of the same cross-section. Any work on electrical equipment entrust a

person with permissions.

If during one of the inspections is detected fault or ineffective operation of safety devic-

es, bring the machine to a safe state or do not connect it to power until safety devices

will be restored to a proper operation.

Fundamental maintenance work in hazardous areas must be carried out by competent

and trained personnel fully understood the risks.

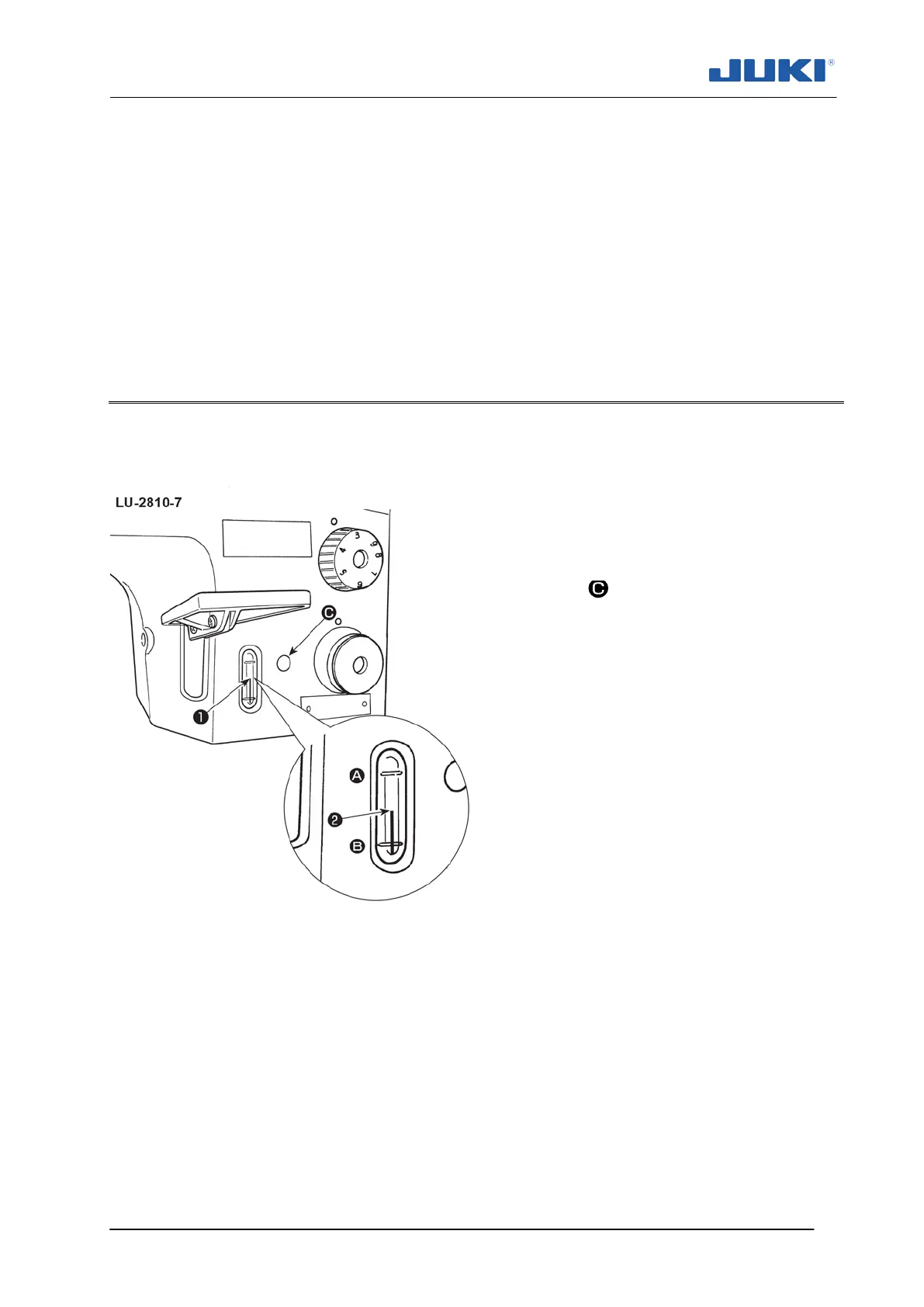

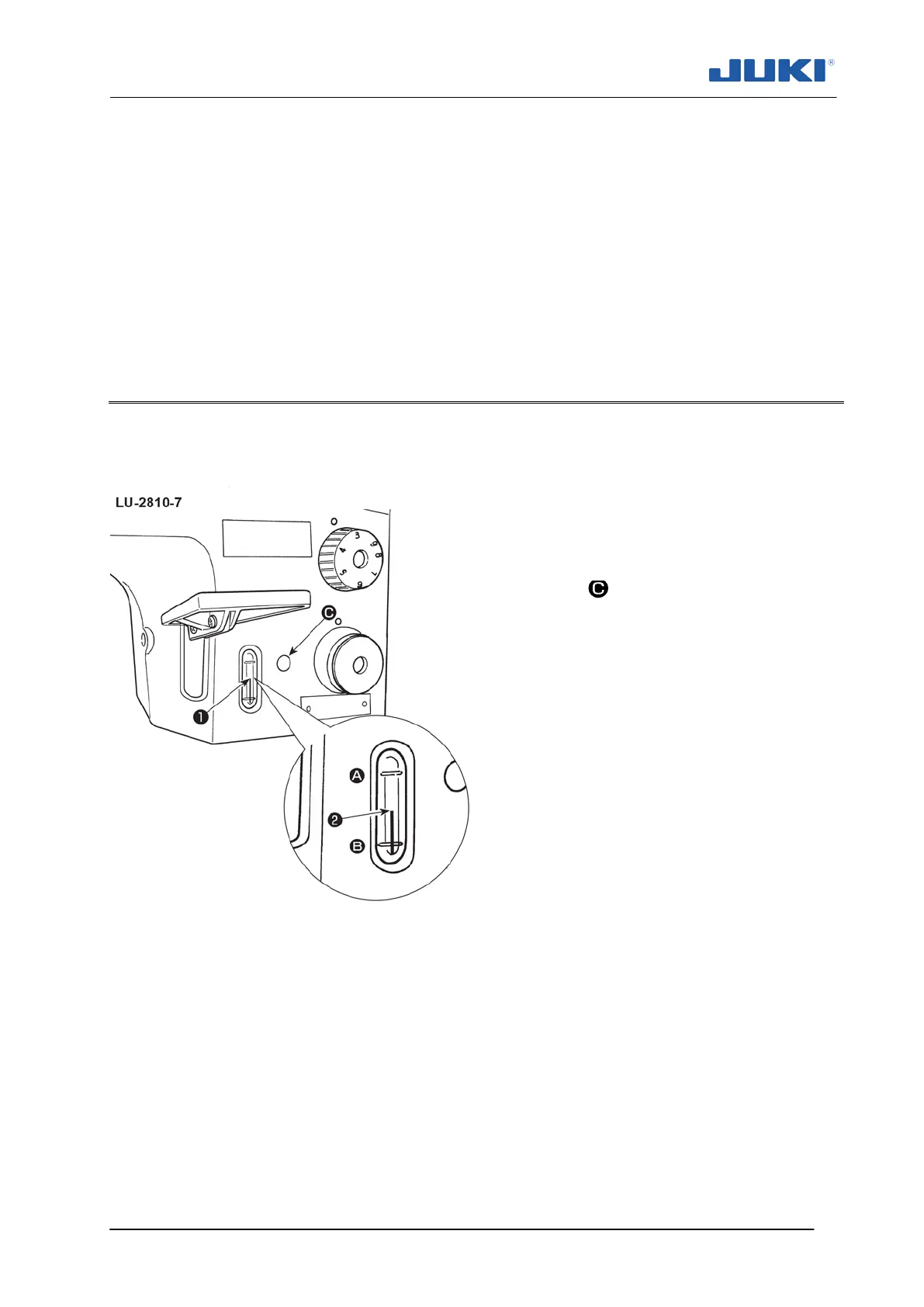

8.2 Lubrication

The machine has a single point requiring lubrication.

Lubrication procedure

Fill the oil tank with JUKI NEW DEFRIX OIL

No.1 (Part No.: MDFRX1600C0) or JUKI

MACHINE OIL #7 (Part No.: MML007600CA)

using the oiler supplied with the machine

from section .

1)

Fill the oil tank with the oil until the top

end of oil amount indicating rod ❷ comes

between the upper engraved marker line

A and the lower engraved marker line B of

oil amount indicating window ❶.

If the oil is filled excessively, it will leak

from the air vent hole in the oil tank or

proper lubrication will be not performed. In

addition, when the oil is vigorously filled, it

may overflow from the oil hole. So, be

careful.

2)

When you operate the sewing machine,

refill oil if the top end of oil amount indicat-

ing rod ❷ comes down to the lower en-

graved marker line B of oil amount indi-

cating window

.

Loading...

Loading...