Industrial Sewing Machine SADE

51

Fig. 25. Statement on touch screen about needle changing

The dialog will close automatically.

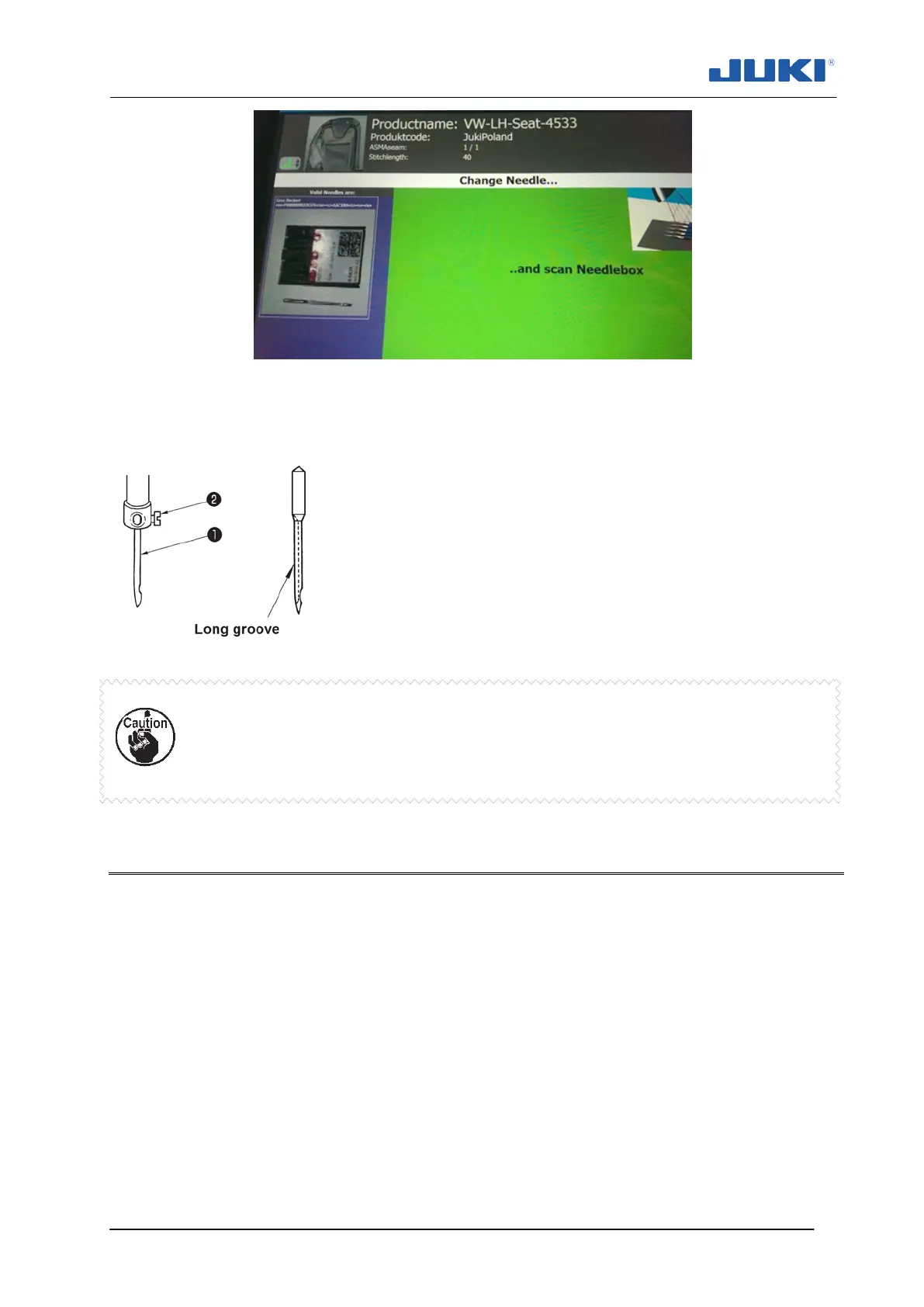

1) Turn the handwheel to bring the needle bar to the highest

position of its stroke.

2) Loosen needle clamp screw ❷. Hold the needle so that the

long groove on needle ❶ faces directly to the right.

3) Push needle ❶ deep into the needle clamp hole until it will

go no further.

4) Tighten needle clamp screw ❷ firmly.

When replacing the needle, check the clearance provided between the nee-

dle and the blade point of hook. (Refer to "6.5. Needle-to-hook relation" p. 61

and "6.6. Adjusting the hook needle guard" p. 63.)

If there is no clearance, the needle and the hook will be damaged.

5.4 Placing thread cones

In many plants top and bottom threads are considered to be critical in relation to the

product. Identification of the threads is therefore required and most of the time you’ll find

barcode readers that will scan for a barcode under the cone.

If so, you’ll have to place the cone so that the barcode is aligned with the scanner. The

cone is properly placed if the barcode reader starts to beep and flash.

Loading...

Loading...