- 92 -

KD 702_1003_1404 Workshop Manual_cod. ED0053029340_1° ed_ rev. 00

188

189

10

190 191

Static injection advance regulation

Fill the tank and operate the fuel pump.

Set the pump/injector delivery control rod (ref. A g. 187) at half-

stroke.

Bring the piston to the top dead centre of compression. Fit a 13

mm hexagon wrench on the injection advance adjusting screw

lock nut. By turning the wrench forth and back you prime the

injection pump, thus enabling the tester to be drained.

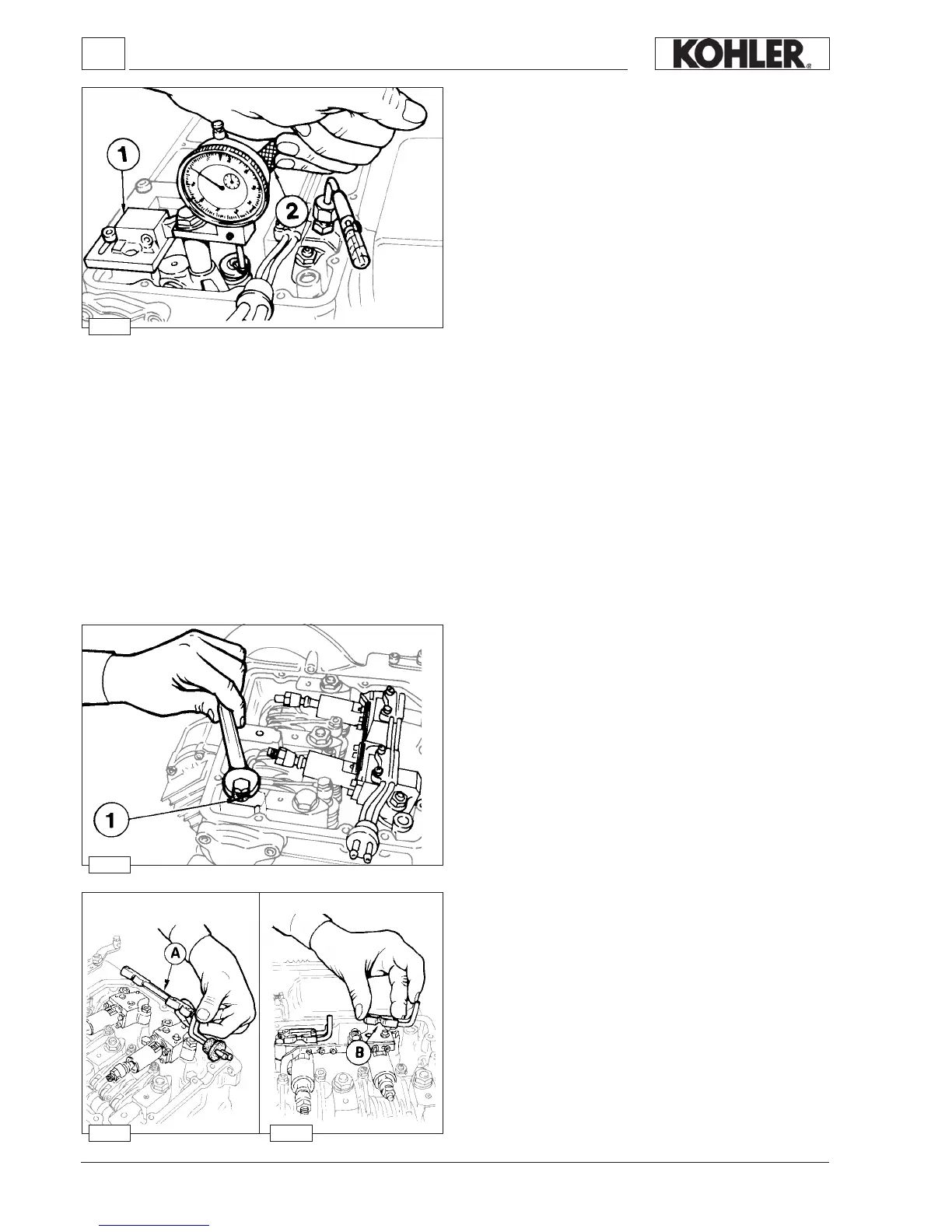

With the piston at its TDC, operate lever 2 (g. 188) and bring

the drain valve into contact with the piston. Then reset dial

gauge.

Go back ¼ of a turn moving the crankshaft anticlockwise. Then

turn forward again very slowly

observing the fuel level inside the tester. As soon as the level

changes, then stop. You reached the static injection advance.

By actuating lever 2 check piston lowering with respect to the

TDC.

The table on page 90 shows both piston lowering expressed in

mm, with respect to the TDC, and the corresponding rotation of

the crankshaft, expressed in degrees.

The static injection advance in degrees a = 11° to 13° refers to

all engines for adjustments from 1500 / 3600 rpm.

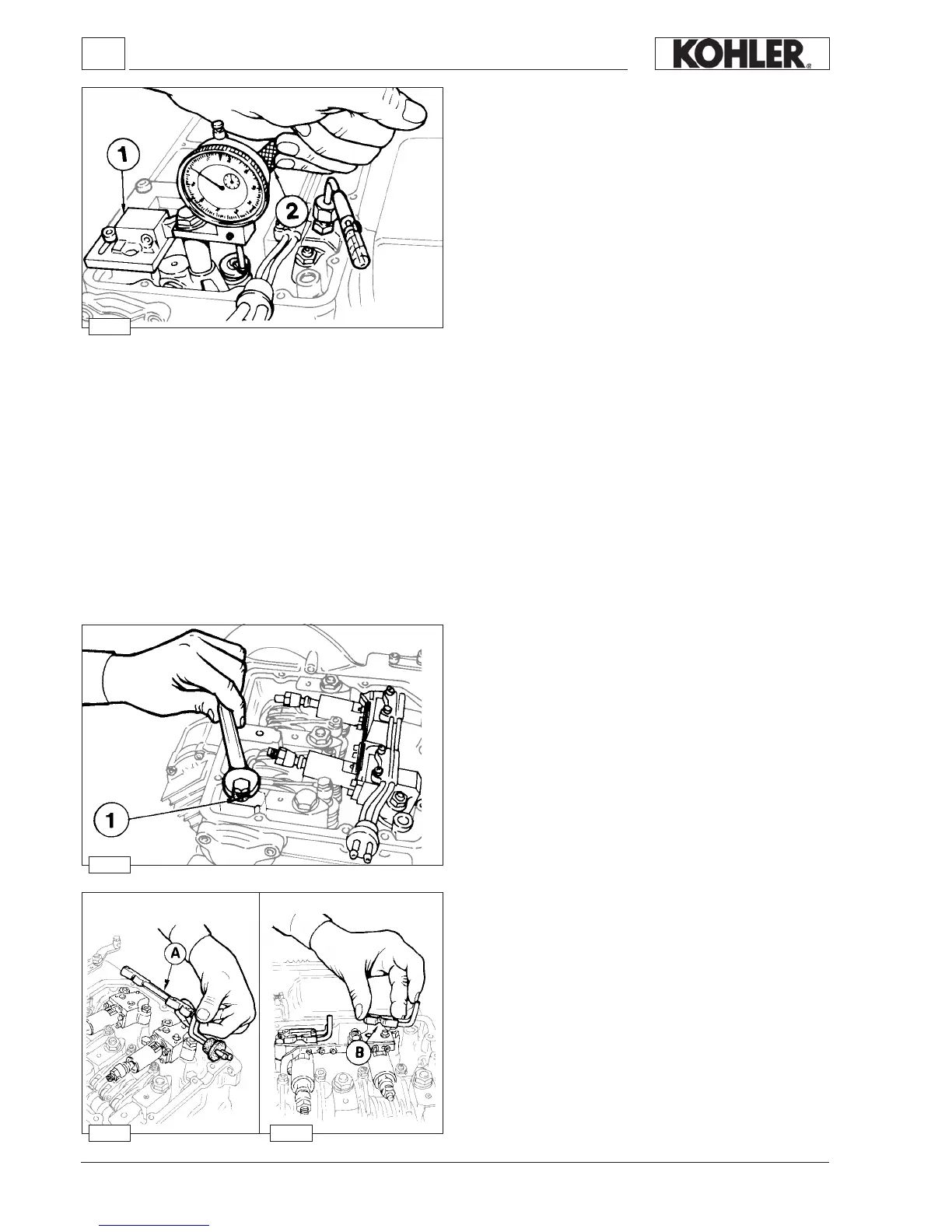

Test head B assembly

Remove fuel pipe A and mount one test head B in its place per

pump/injector.

The test heads complete with pipes are supplied together with

instrument ref. 7104-1460-069.

Preliminary steps to pump/injector unit delivery balancing test

Closing the oilhole

To perform this test you must remove the rocker arms cover

and close hole 1 with an M 8x1.25 or M 10x1.5 screw (on latest

model engines) not longer than 8 mm. Also remove the copper

gasket.

If the camshaft and rocker arms are dry, lubricate them with

engine oil.

Note:

If you only want to check the nozzle it is not necessary to

balance the deliveries; provided that when you dismount

the rod you do not loosen adjusting screws (1 and 2 ,g.

193).

Fuel system

Loading...

Loading...