Loading...

Loading...

Do you have a question about the Komatsu PC16R-3 and is the answer not in the manual?

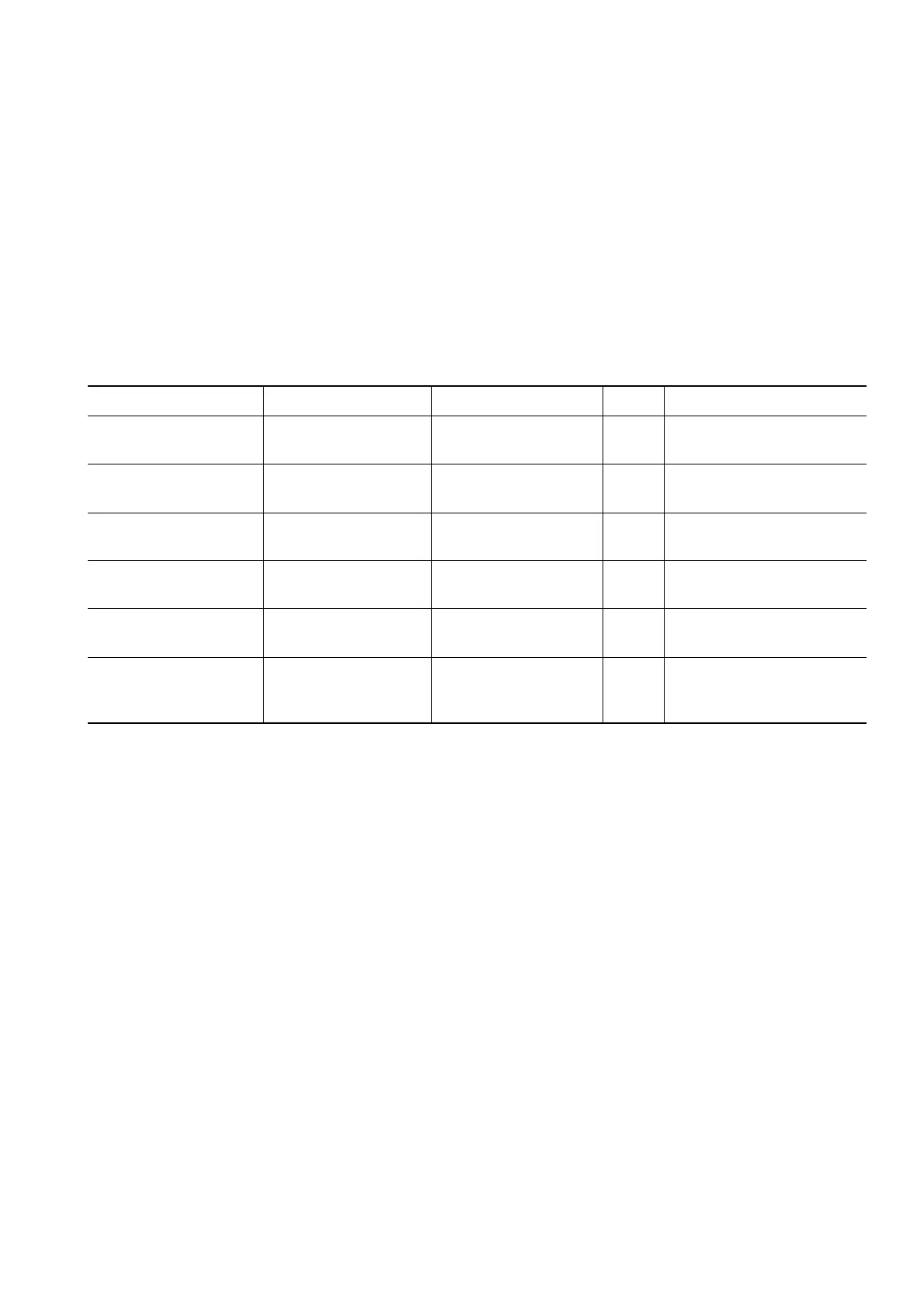

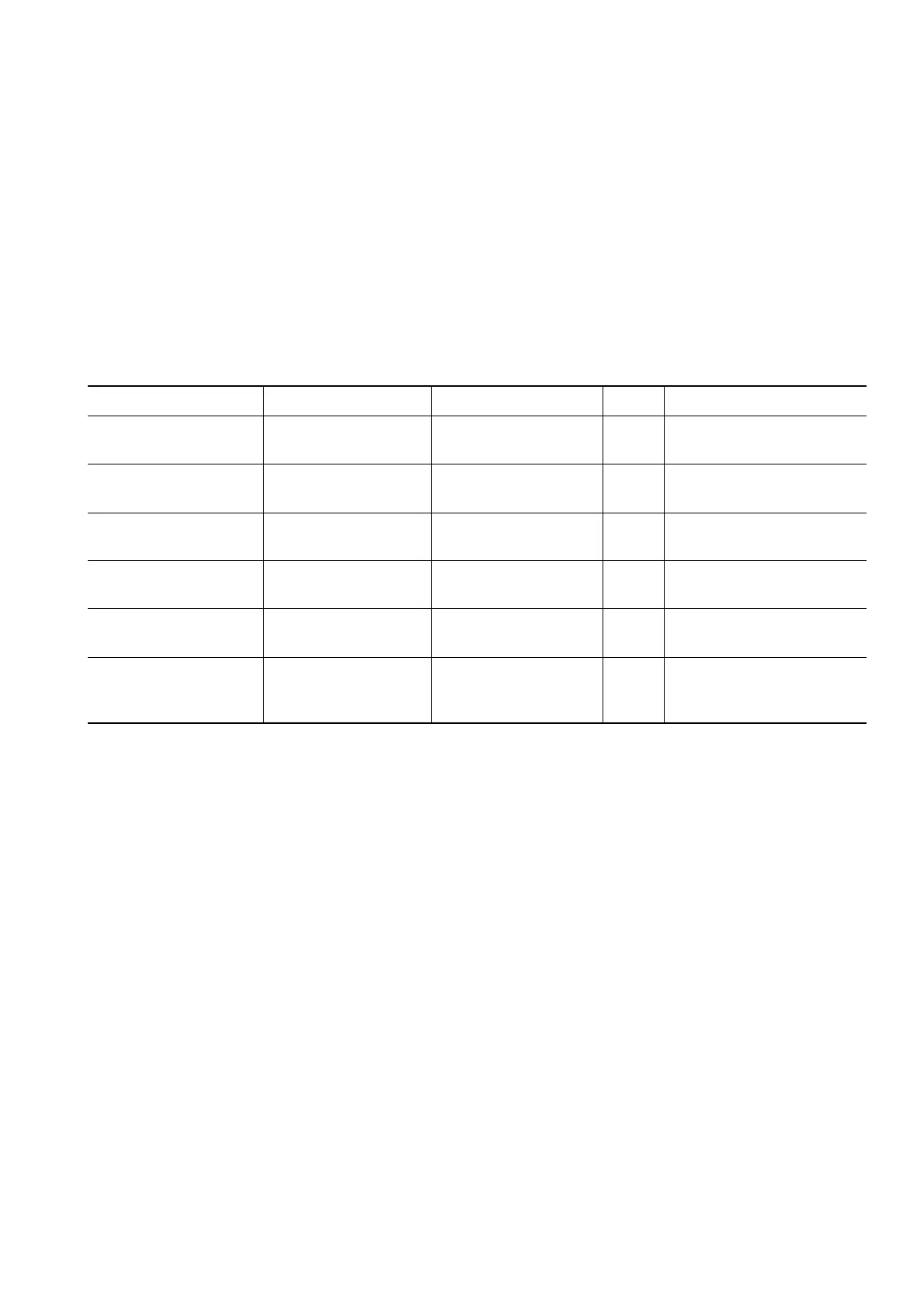

| Brand | Komatsu |

|---|---|

| Model | PC16R-3 |

| Category | Excavators |

| Language | English |

Essential safety regulations, warnings, and precautions for operating and maintaining the machine.

Covers essential safety rules, behavior during anomalies, safety devices, and personal protective equipment.

Outlines critical checks and safety measures to perform before starting the machine's engine.

Provides guidance on safe operating practices, including starting, moving, working on slopes, and hand signals.

Details all instruments, gauges, switches, and controls necessary for operating the machine safely.

Lists essential visual checks and operational procedures required before starting the machine's engine.

Explains the procedures for starting the engine in both warm and cold climates, including critical safety steps.

Covers preliminary operations, forward/reverse movement, stopping, steering, and track gauge adjustments.

Offers solutions for common problems related to electrical circuits, frame, engine, and other machine components.

Covers general safety, waste disposal, special warnings, and basic maintenance guidelines for the machine.

Details safety-related parts that need periodic inspection and replacement to ensure machine safety and fire prevention.

Outlines the recommended maintenance schedule based on operating hours and specific conditions.