Repair manual KTM LC4 Art.-Nr. 3.206.014 -E

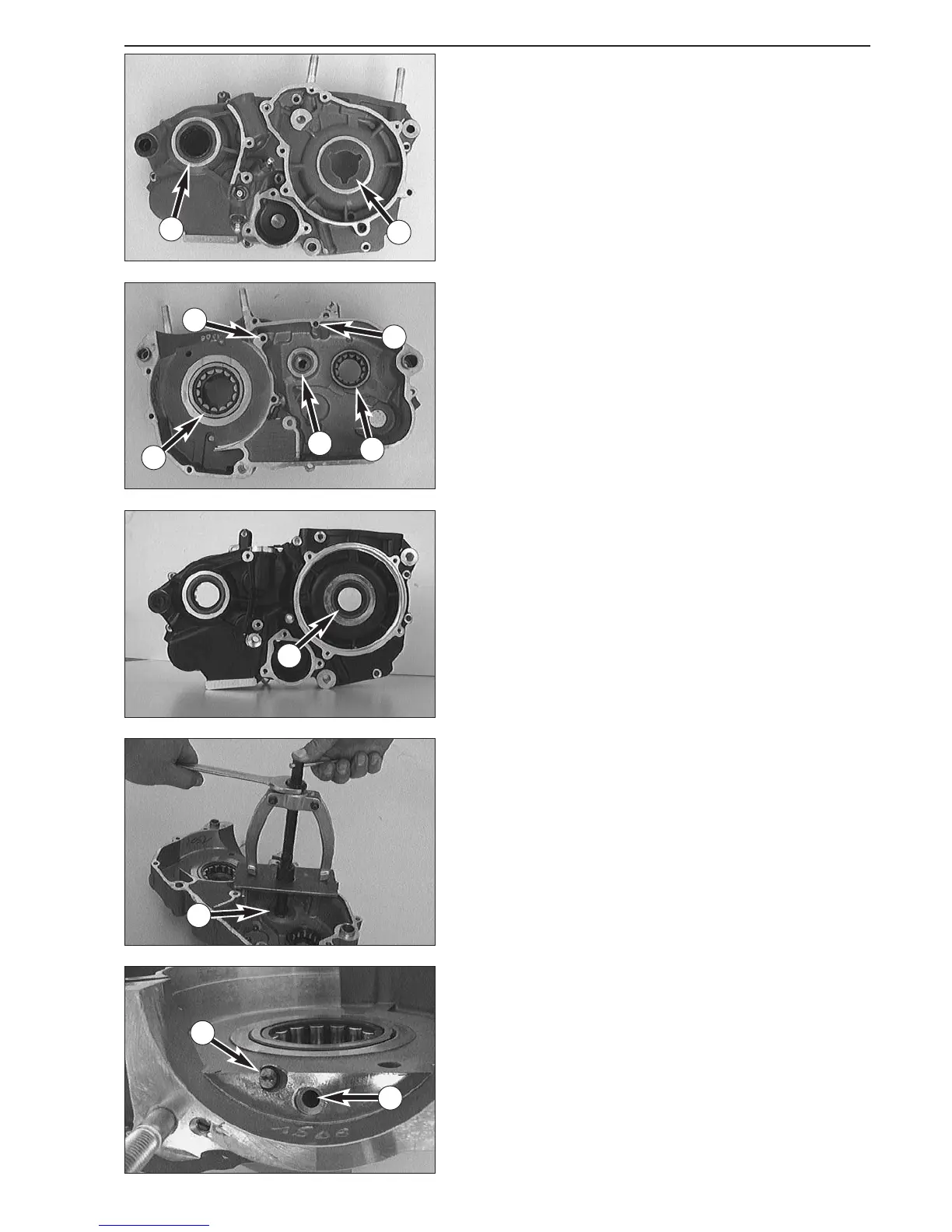

Working on the right housing half

Remove shaft seal rings and heat housing half to approx. 150° C by

means of a hot-plate.

Roller bearing of crankshaft

1

Proceed as for left housing half.

Cylinder roller bearing of counter shaft

2

Remove shaft seal ring. Press old bearing inwards. Press in new bearing

from inside as far as stop.

Oil ducts

3

Use compressed air to clean all oil ducts. Ensure that the oil ducts are

not clogged.

Counter shaft seal ring

4

Press in new shaft seal ring from outside until flush.

Crankshaft seal ring

8

Press in new shaft seal ring from outside until flush.

NOTE: Engine with an electric starter have a stop disk instead of the

shaft seal ring

5. Do not remove this disk.

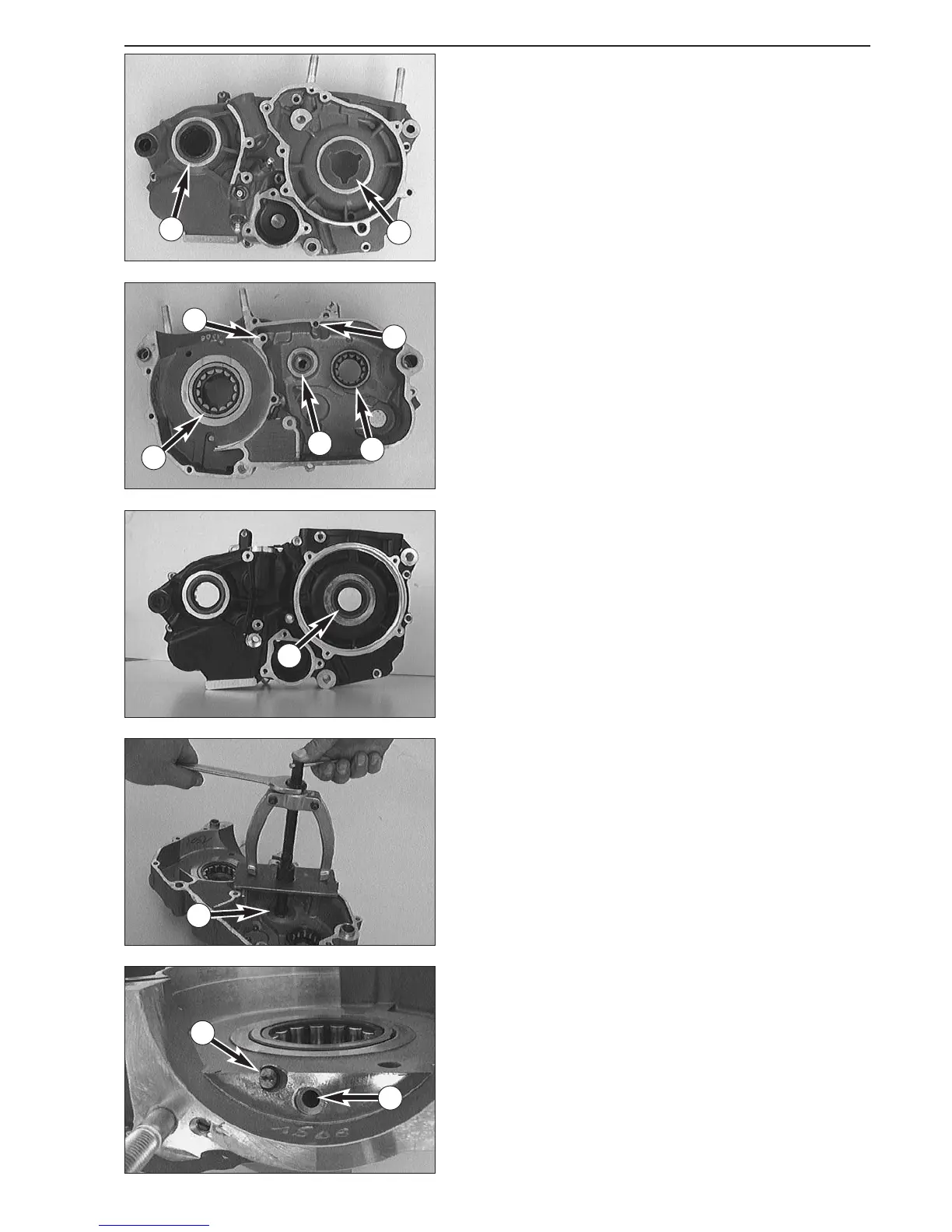

Needle bearing of main shaft

6

Pull old bearing from bearing seat using bearing extracto

151.12.017.000 and insert. In order to apply the bearing extractor in an

vertical position, a steel plate (see special tools) must be laid on the

sealing area of the housing. The bearing extractor jaws should fit as

close as possible up to the housing walls. Then press in new bearing

from inside until flush.

Oil nozzle

7

For the cleaning of the oil nozzle and the oil duct simply blow it

through with compressed air from the nozzle side. If the oil nozzle is

disassembled, secure it with Loctite 243 when mounting again.

Then check the lubrication bore

A of the crankshaft roller bearing for

free passage.

After the case half has cooled down, check bearings for secure fit.

5-3E

1

2

3

3

5

4

6

6

7

A

8

Loading...

Loading...