Repair manual KTM LC4 Art.-Nr. 3.206.024 -E

5-7F

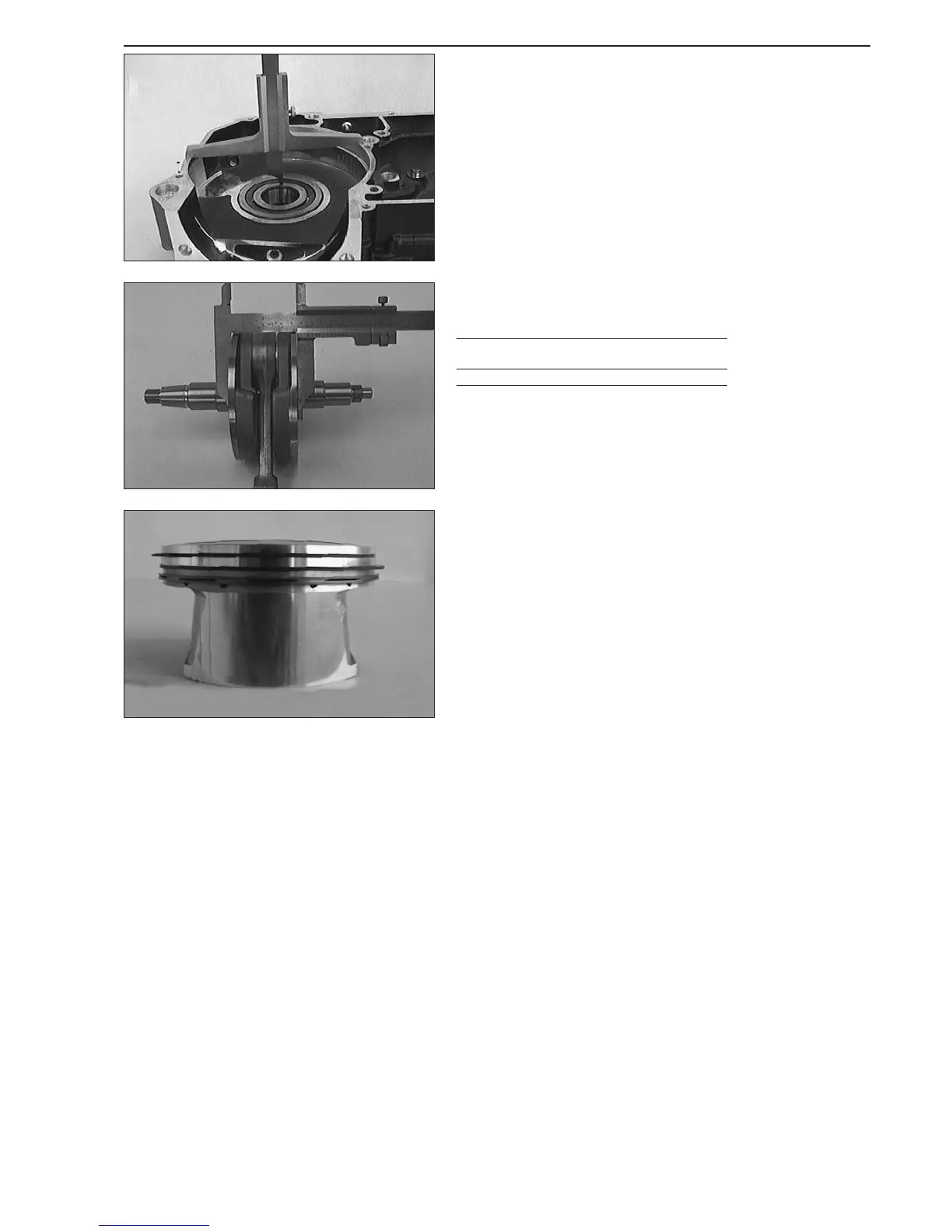

Measuring and adjusting of crankshaft axial clearance

– Should the crankshaft, engine housing, or a roller bearing be

replaced, the axial clearance of the crankshaft should also be

checked.

– The housing should be laid inside upwards, then measure the

distance from the sealing area to the inner rings of the roller

bearings. Note the readings and then add on 0.3 mm to allow for

gasket thickness.

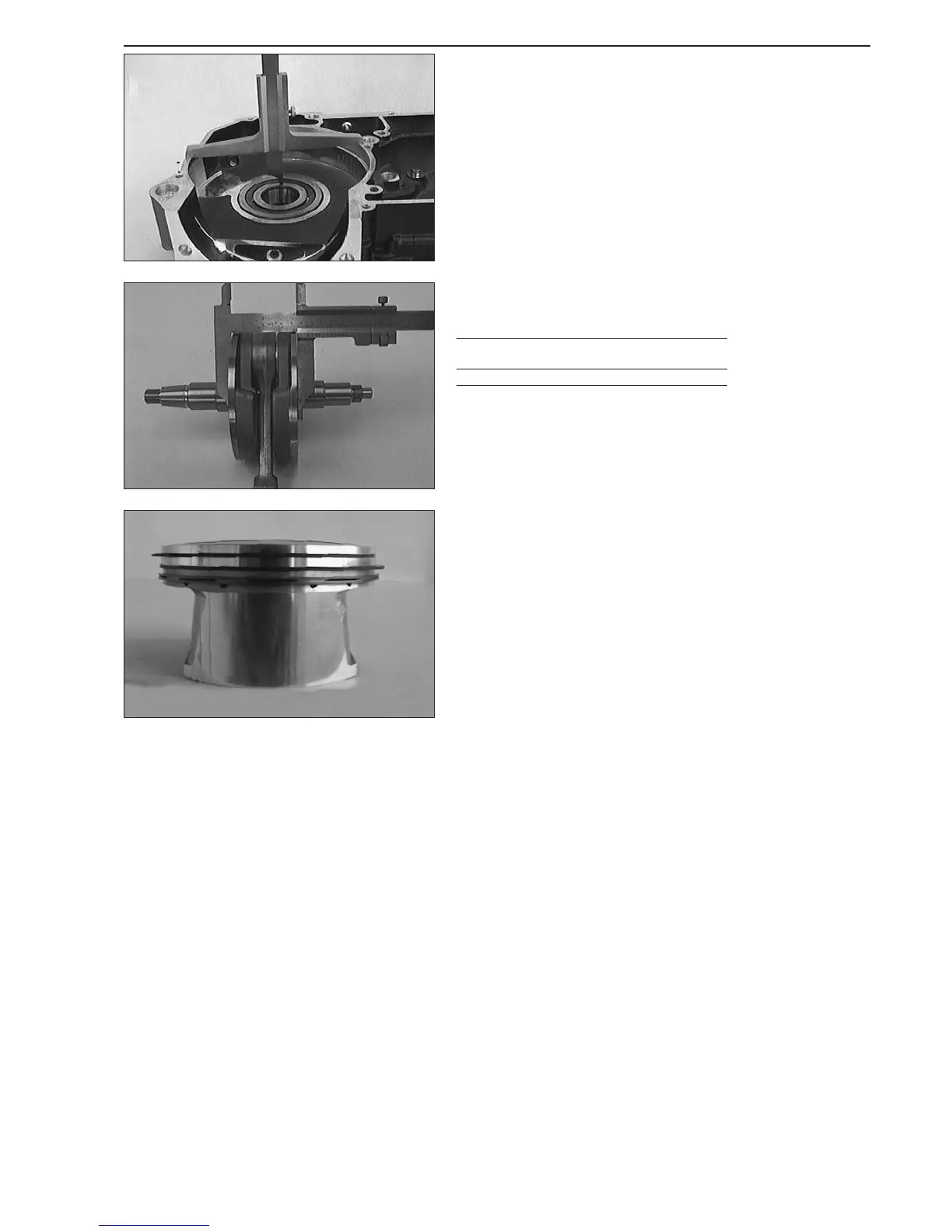

– Measure the crankshaft at touching points and then subtract the

measured value from the housing dimensions. This figure will be

the axial play of the crankshaft, which should be 0.03 - 0.12 mm

(up to model 2003). From model 2004: 0,10 - 0,20 mm (660

Rally 0,15 - 0,25 mm).

EXAMPLE:

Left-hand housing half 33.0 mm

Right-hand housing half + 32.8 mm

Gasket + 0.3 mm

Total housing dimension = 66.1 mm

Crankshaft dimension – 65.8 mm

Axial play present = 0.3 mm

The compensating washers should be equally distributed between the

two sides of the crankshaft. In our example, one compensation washer

(0.1 mm / 0.004 in.) must be mounted on either side.

Checking the piston

– Replace the piston in the case of excessive oil consumption or

grooves in the piston skirt.

– If reinstalling the old piston perform the following steps:

1. Piston bearing surface - check for damage

2. Piston ring grooves - the piston rings must move easily in the

groove. Old piston rings or sandpaper (400 grit) may be used to

clean the piston ring grooves.

3. Piston rings - check for damage and end gap (see below).

4. The piston pin must move freely in the piston when mounted. If the

piston pin changed its color badly or shows running traces, it must

be replaced. Insert piston pin also into the conrod and check for

clearance. Maximum clearance in the conrod eye 0.08 mm (0.003

in).

NOTE: When in place, the piston pin may not have any play. It must

be possible to shift it with slight counterpressure.

Loading...

Loading...