5-18E

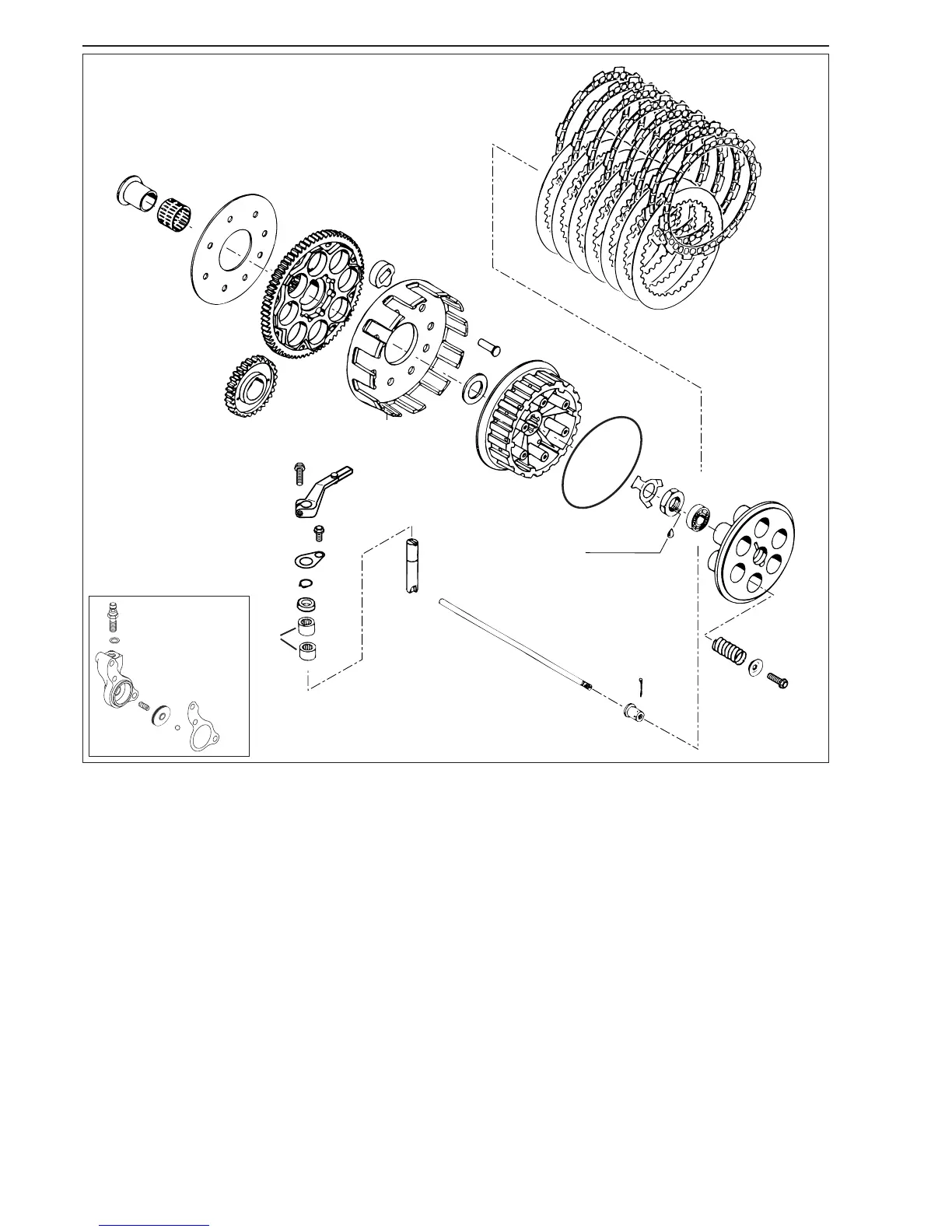

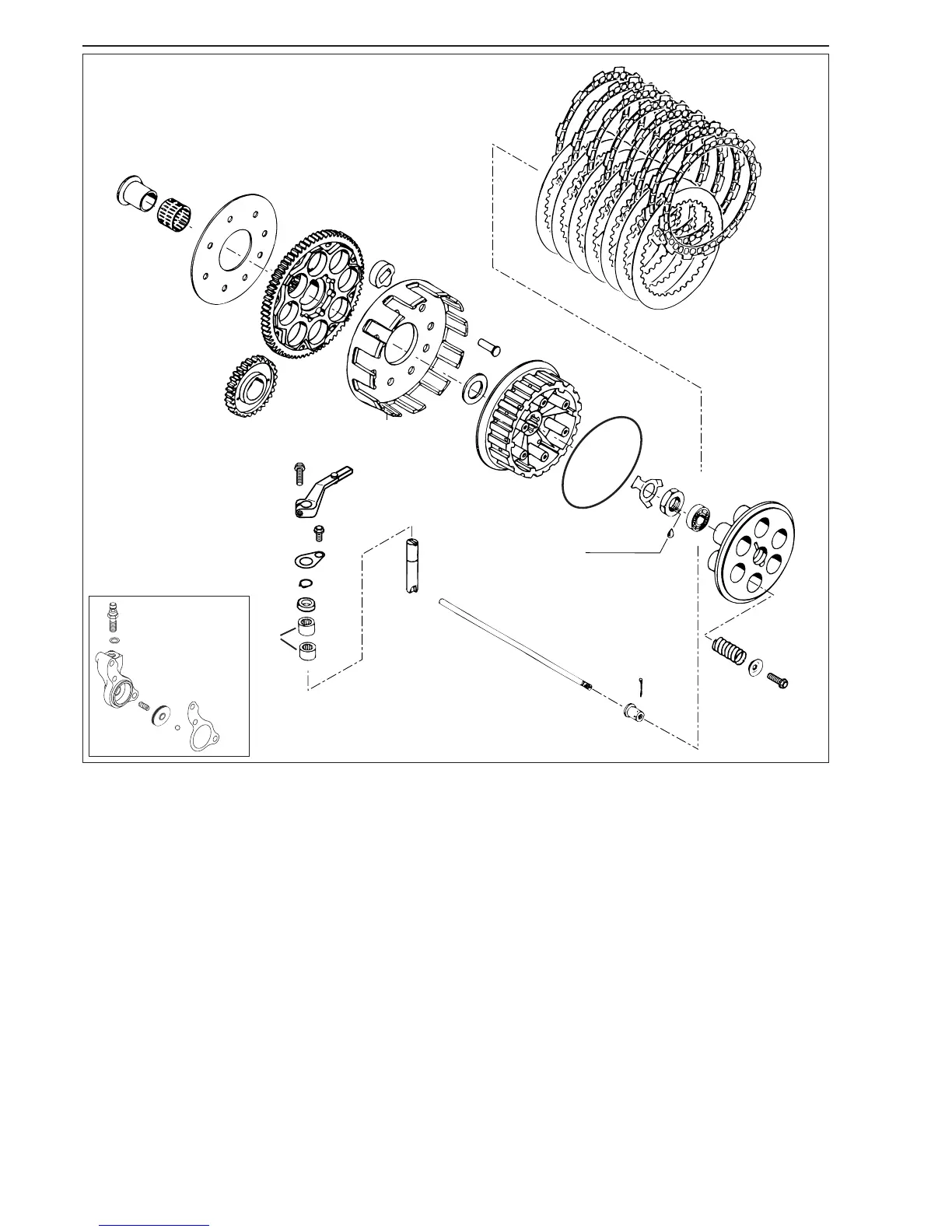

Checking the clutch components for wear

Thrust bearing 1 – Check for signs of wear.

Push rod

2 – Check the face side for signs of wear.

Clutch release shaft

3, sealing cup 4 and needle bearing 5 – Check for damage and signs of wear.

Clutch pressure springs

6 – Minimum length: 34.5 mm (1.36 in) (length/new spring: 37 mm (1.457 in)) / 660 SMC Minimum

length: 31.5 mm (1.26 in) (length/new spring: 33.5 mm (1.34 in)).

Replace all 6 springs if necessary.

Clutch discs

7 – Clutch discs must be plane.

7 steel discs ≠ 1.5 mm (0.066 in) must be free of grooves.

8 lining discs ≠ 2.7 mm (0.106 in), wear limit: 2.5 mm (0.1 in)

Inner clutch hub

8 – Check both the exterior and the interior toothing for signs of wear.

Needle bearing

9 – Check for signs of wear.

Outer clutch hub

bk – Check if all rivets bm are tight.

Absorbing elements

bl

Power transmission from the primary drive to the clutch is cushioned by rubber elements bl. These rubber elements must be

checked in the course of normal checking for signs of wear. It is recommended to check the elements while disassembling the

engine. Try to turn the outer clutch hub after removing the inner clutch hub (engine will lock). Dead travel should be impossible.

Check O-ring

bo for brittleness and cracks. If the cross section of the O-ring is oval (deformed) replace the O-ring.

Loading...

Loading...