5-6E

Crankshaft

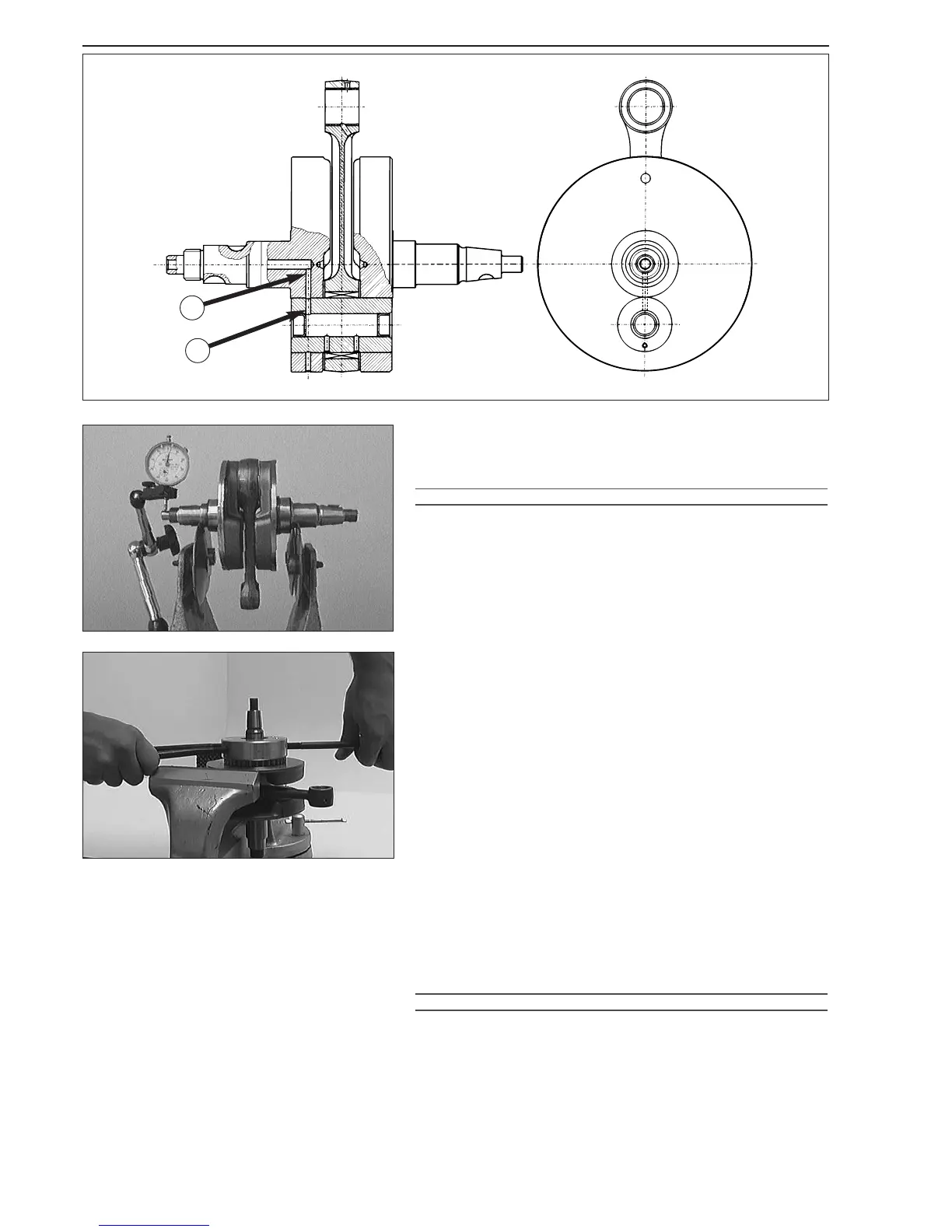

If the conrod bearing is replaced, take care to properly position the

crankpin. The bores of the crank web

B and crank pin C must

coincide.

!

CAUTION

!

IF THE CRANK PIN IS PRESSED IN THE WRONG POSITION, THE CONROD BEARING IS

SUPPLIED INSUFFICIENTLY OR NOT AT ALL WITH ENGINE OIL

, WHICH RESULTS IN

BEARING DAMAGE

.

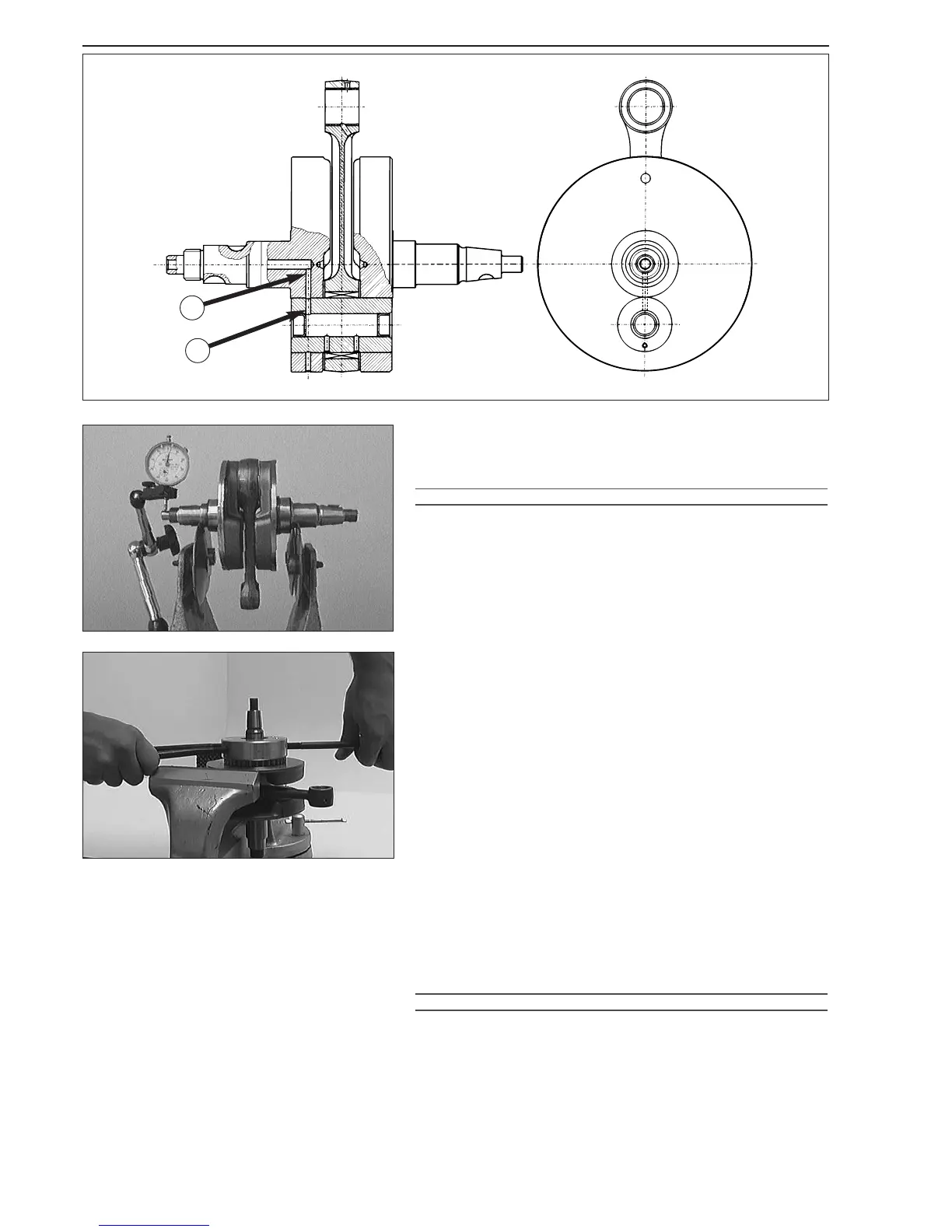

If the crankshaft is continued to be used, check crankshaft journals for

run out. Place crankshaft on a roller block or a similar device and check

the outer end of the journals for run out with a dial gauge.

run out of crankshaft journals: max. 0.08 mm (0.0032 in)

The radial clearance and axial clearance on the conrod bearing must be

checked.

radial clearance: max. 0.05 mm (0.0019 in)

axial clearance: max. 1.10 mm (0.044 in)

– If the crankshaft roller bearings are replaced, the inner rings on the

crankshaft should also be changed.

– Heat special tool 584.29.037.040 or 584.29.037.043 on a heating

pad up to approx. 150°C and slip it on the inner ring immediately.

Press the special tool together tightly to obtain a good heat transfer

and pull the inner ring off the crankshaft.

–To mount the new inner ring, heat the special tool 584.29.037.040

or 584.29.037.043 again to approx. 150°C, engage the inner ring

and slip it on the crankshaft journal immediately.

– In order to safely press on new rings, a middle panel should be

inserted between the crankshaft webs. This panel should be big

enough to be supported on both sides, so that the crankshaft lies

free and accessible.

NOTE: Because LC4-E models have different diameters of inner

crankshaft bearing rings, it is necessary to have both special tools

(584.29.037.040 and 584.29.037.043).

!

CAUTION

!

NEVER CLAMP THE CRANKSHAFT WITH A CRANKSHAFT JOURNAL OR WEB IN THE

VICE

, AND NEVER TRY TO KNOCK THE INNER RING FREE. THE CRANKSHAFT WEBS

MAY BE COMPRESSED THEREBY MAKING THE CRANKSHAFT UNUSEABLE

.

B

C

Loading...

Loading...