5-23F

Repair manual KTM LC4 Art.-Nr. 3.206.024 -E

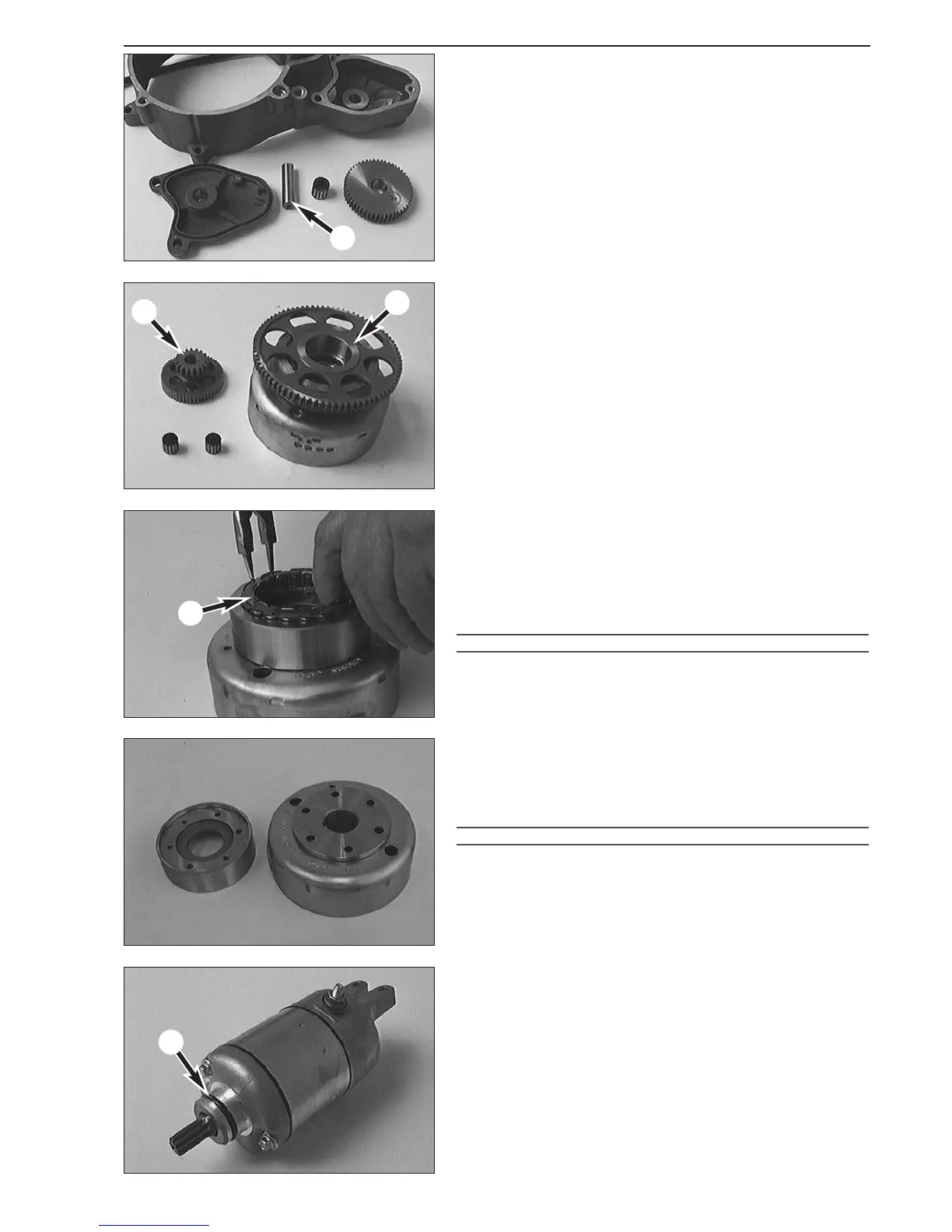

Removing the intermediate gear

– Remove the starter cover.

– Pull out the bearing bolt

1.

– Remove the intermediate gear and the needle bearing.

– Check the parts for signs of wear.

– Insert the intermediate gear with the collar downward into the

housing for preassembly.

– Oil the needle bearing and install it with the bearing bolt.

– Do not yet replace the starter cover.

Checking the freewheel

– Insert the freewheel gear 2 into the freewheel.

– The freewheel gear must turn clockwise.

– The freewheel gear must lock without empty run if turned

anticlockwise.

– Check the reduction gear

3 and the needle bearings for signs of

wear.

– Check the needle bearing of the freewheel gear for signs of wear.

Replacing the freewheel hub

– Squeeze the spreader ring 4 with the circlip pliers and remove it

together with the freewheel.

– Check the freewheel segments for signs of wear.

– Check the freewheel hub sections at the freewheel running surface

for signs of wear.

– Heat the flywheel to a temperature of approx. 80° C (176° F) and

remove the 6 bolts.

!

CAUTION

!

M

AKE SURE THAT THE FLYWHEEL IS NOT HEATED BEYOND

80° C (176° F) TO

AVOID LOOSENING OF THE MAGNETS

.

– Carefully tap the side of the freewheel hub with a plastic hammer

and take off the freewheel hub.

– Mount the freewheel hub on the flywheel.

– Clean the thread on the screws and apply Loctite 2701.

– Mount the M6x12.5 screws (2 pieces, strength class 8.8, with dog

point) and tighten to 12 Nm.

– Mount the M6x12 screws (4 pieces, strength class 12.9, without

dog point) and tighten crosswise to 16 Nm.

!

CAUTION

!

A

LWAYS USE NEW BOLTS (12.9) AND APPLY LOCTITE 2701 TO THE THREADS.

– Thoroughly oil the free-wheel and insert it into the freewheel hub.

– Insert the spreader ring into the groove with a pair of circlip pliers

and make sure that it properly rests in the groove.

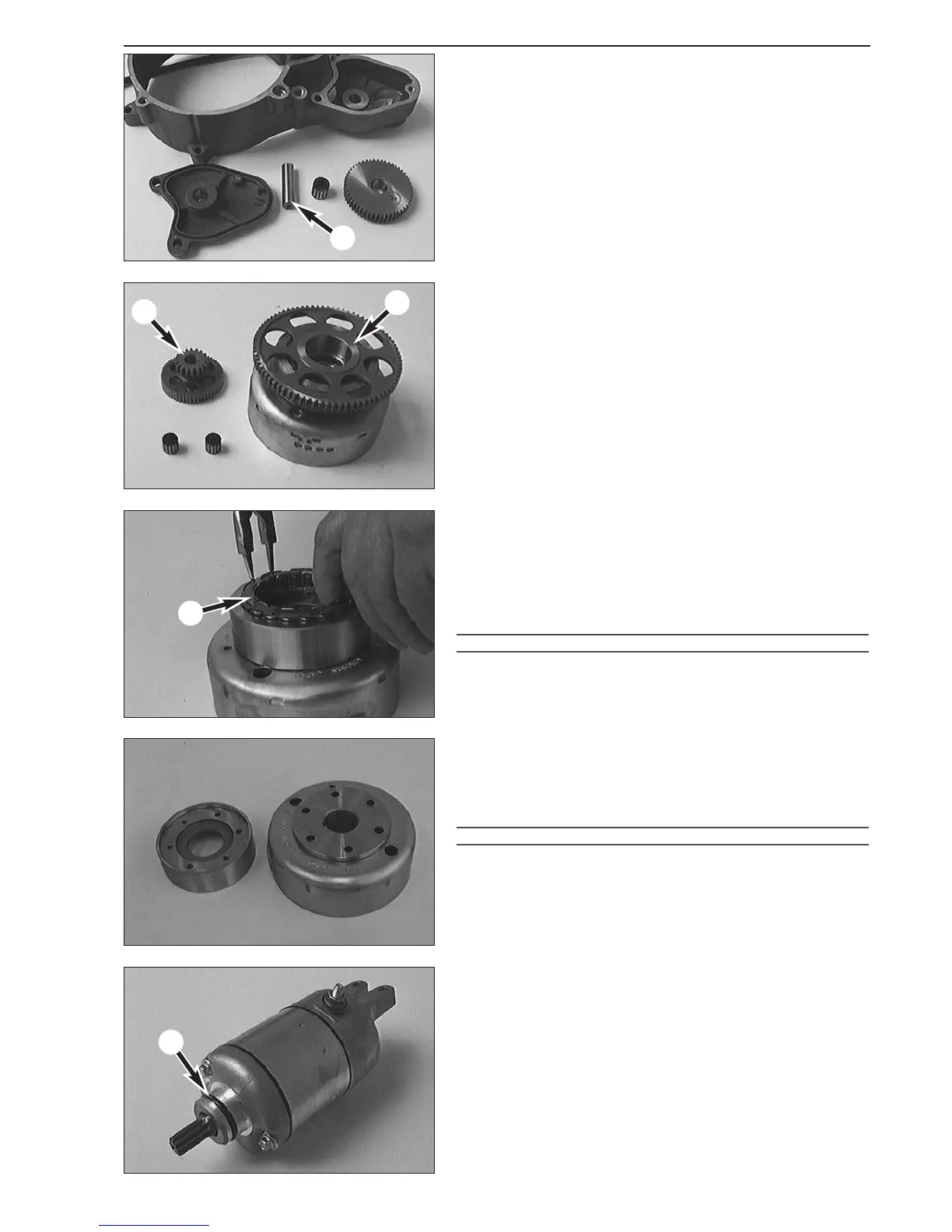

Electric starter motor

– The starter showed only slight signs of wear after 10.000 starting

processes, and exchanging individual parts must be considered

uneconomical. Therefore, such work is not described in the present

documentation.

– Exchange the O-ring

5 at the starter flange (incl. in the gasket

set).

1

2

3

4

5

Loading...

Loading...