Wiring the standard device

Basic devices in the power range 75 ... 90 kW

Motor connection

5

5.7

5.7.4

5.7-8

EDSVF9333V EN 3.0-06/2005

Features of the connection for motor temperature monitoring:

Pin X8/5, X8/8 from incremental encoder input (X8)

Connection Linear KTY thermal sensor

Tripping point z Warning: Adjustable

z Error (TRIP): Fixed at 150 °C

Notes z Monitoring is not active in the Lenze setting.

z The KTY thermal sensor is monitored with regard to interruption

and short circuit.

T1

T2

PE

U

VW

2

3

4

0

M4 x 12: 2.5 Nm (22.1 lb-in)

M5 x 12: 3 Nm (26.5 lb-in)

U, V, W,

PE

M10

30 Nm

264 lb-in

1

a

}

+

PE

9300vec125

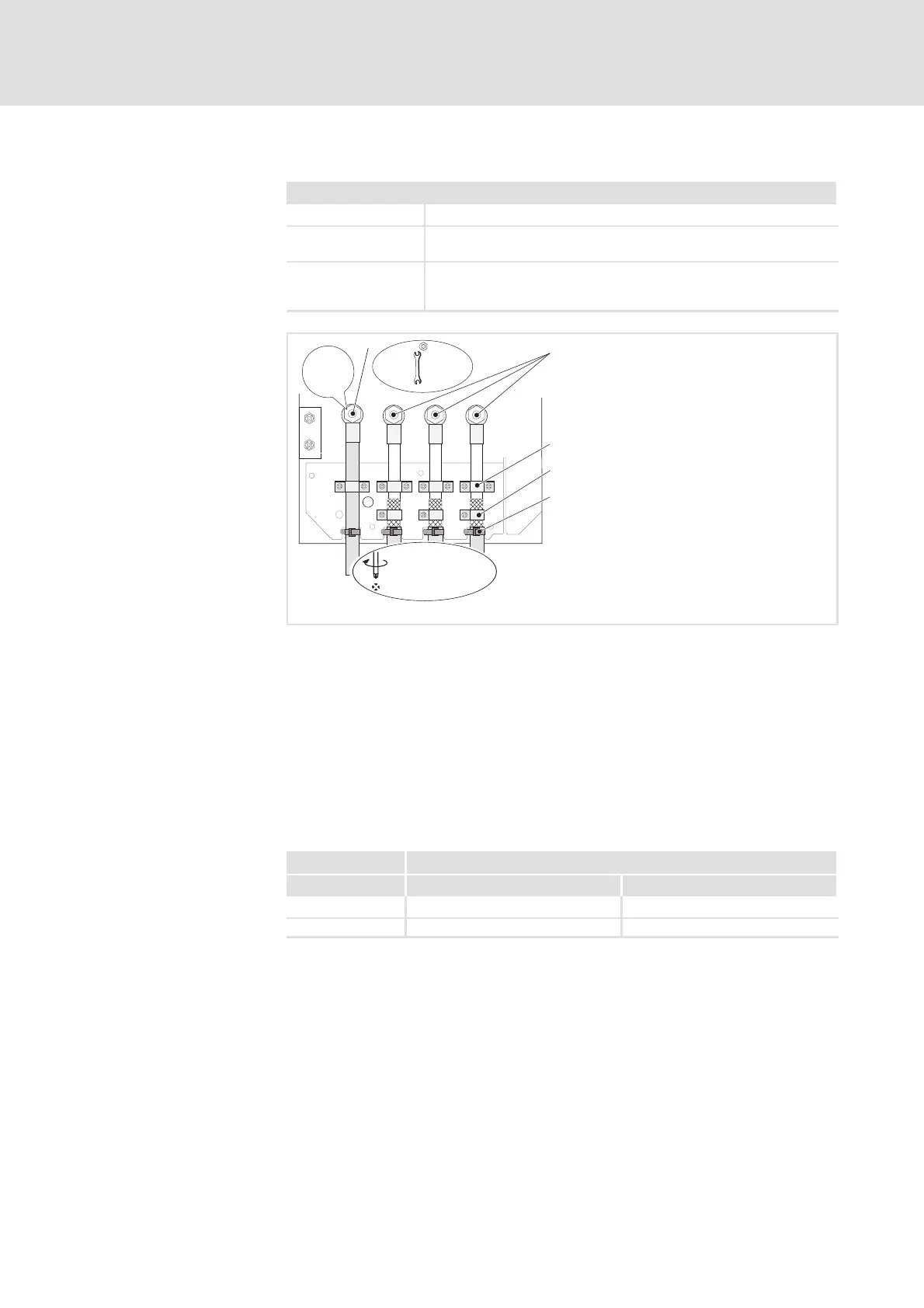

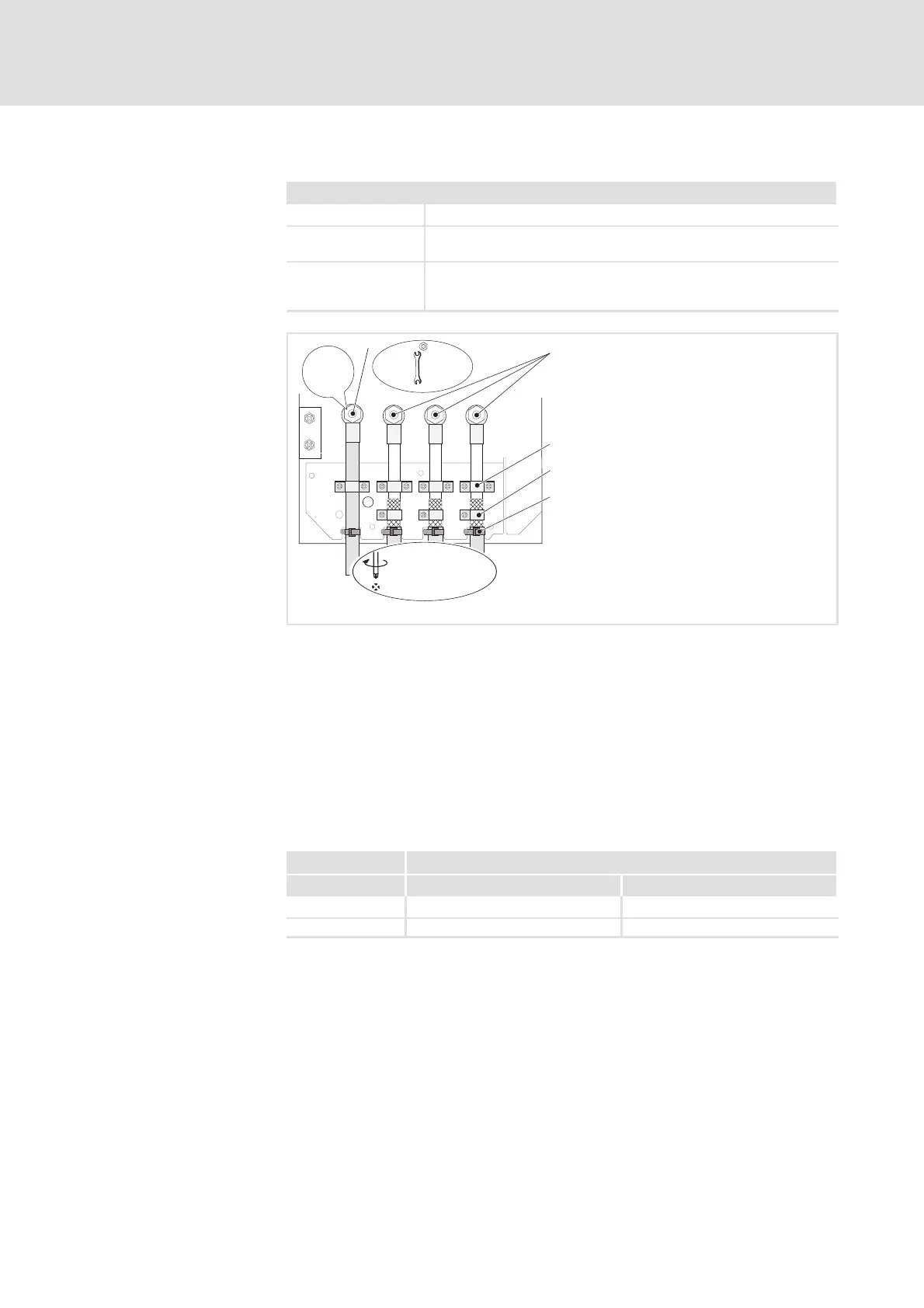

Fig. 5.7-6 Motor connection with KTY thermal sensor

PE stud

Connection of PE cable

U, V, W

Connection of motor cable with ring cable lugs

Observe correct polarisation. Observe maximum length of motor cable.

Cable clamps for strain relief of motor cable

FastencableclampswithM4×12mmscrews

Shield clamps

Place shields of motor cable with large surface on the shield sheet and

fastenwithshieldclampsandM5×12mmscrews

Cable ties for additional strain relief of motor cable

9300 vector Cablecross-sectionsU,V,W,PE

Type [mm

2

] [AWG]

EVF9332 95 3/0

EVF9333 120 4/0

Cable cross-sections

Loading...

Loading...