Troubleshooting and fault elimination

Error elimination

Error messages at the keypad or in the parameter setting program Global Drive Control

9

9.4

9.4.4

9.4-8

EDSVF9333V EN 3.0-06/2005

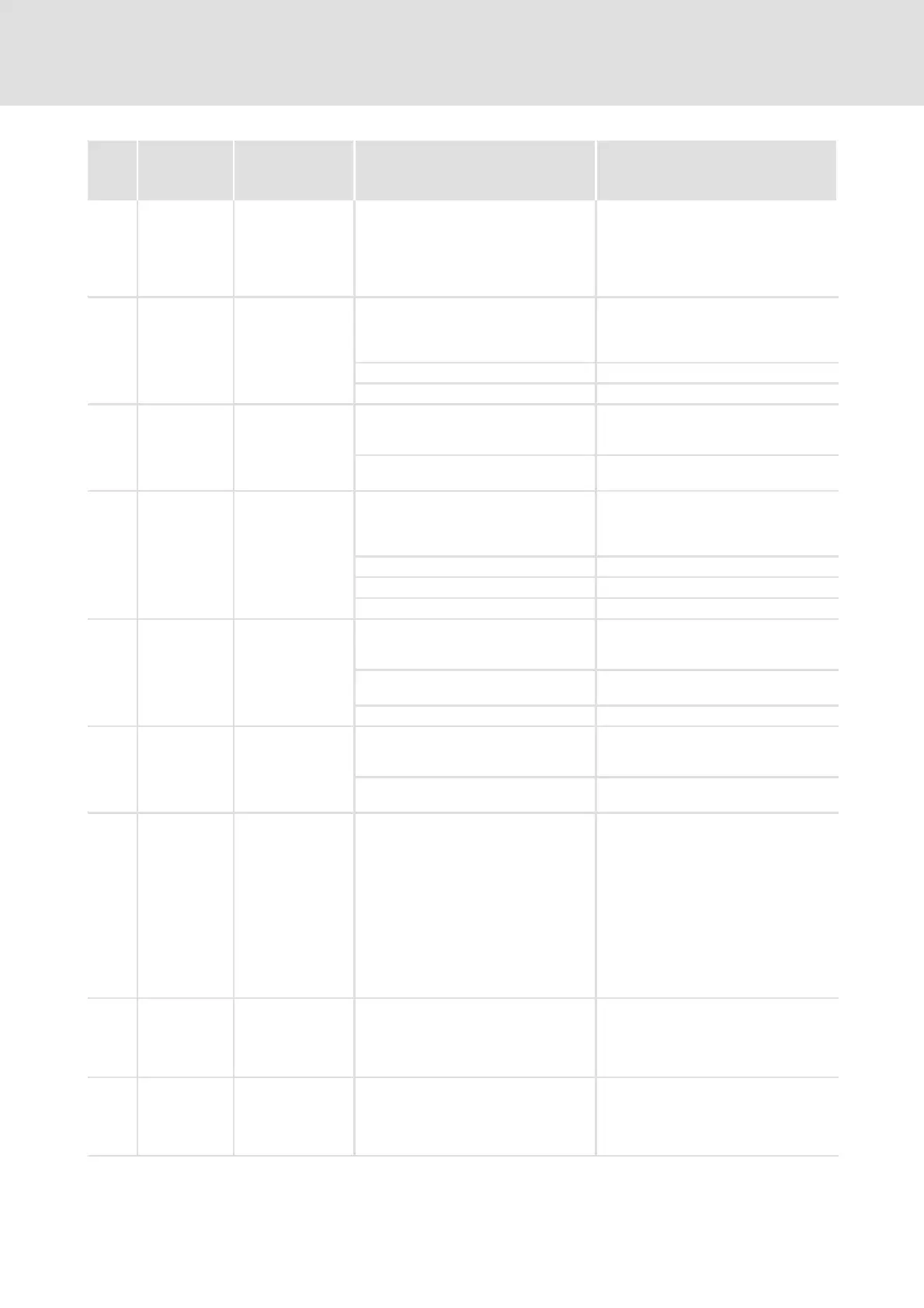

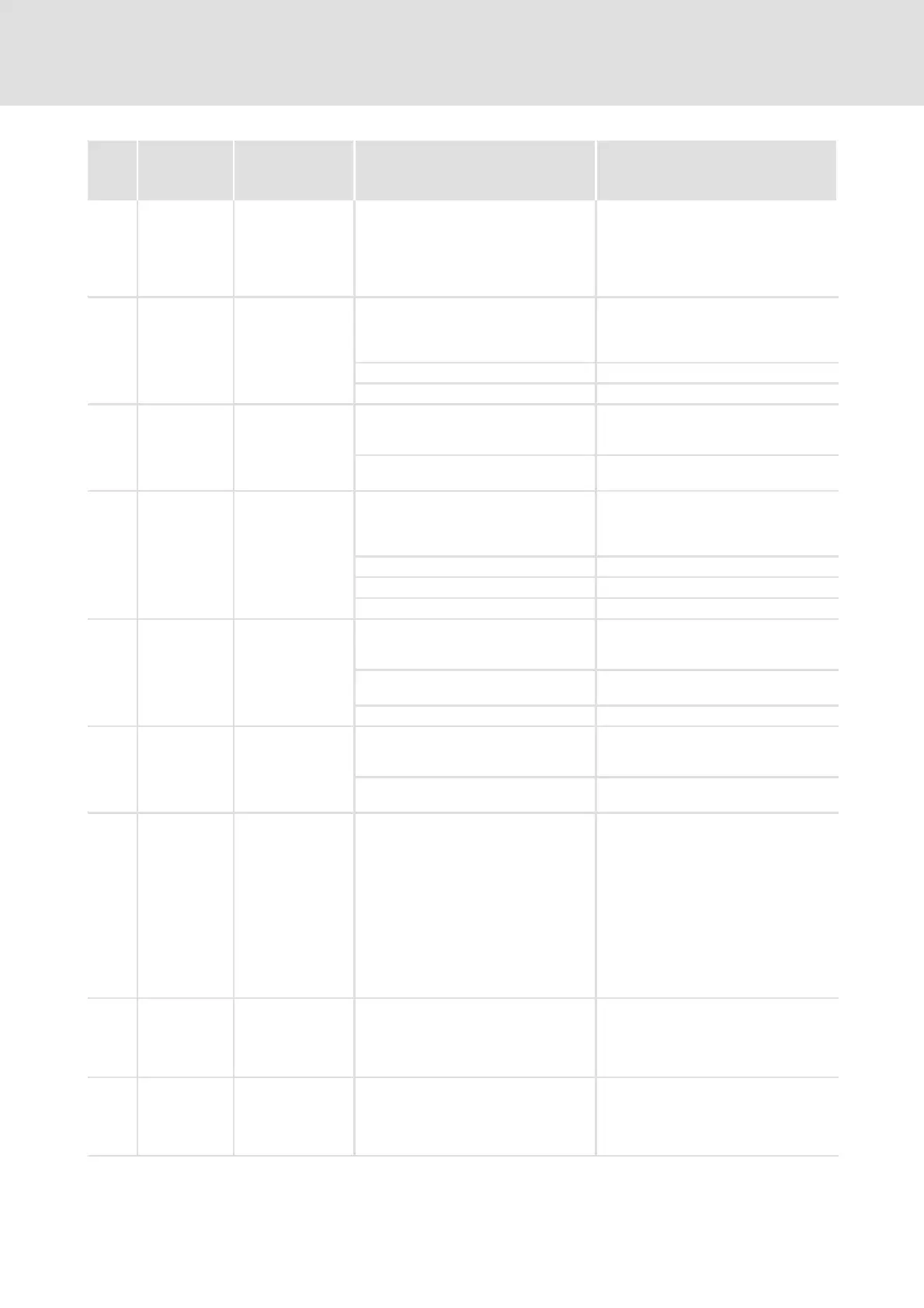

RemedyCauseFaultError number

x=0:TRIP

x = 1: Message

x=2:Warning

Error

code

Reversed motor phases when operating

with feedback or reversed encoder

tracks so that the direction of rotation

has changed

z Check the motor cable connection for

correct phase position

z If possible, operate the motor with

deactivated feedback (C0025 = 1) and

check the direction of rotation of t he

motor.

OH x050 Heatsink

temperature is

higher than the

value set in the

controller

Ambient temperature T

u

>40°Cor50°C z Allow controller to cool and ensure

better ventilation

z Check ambient temperature in the

control cabinet

Heatsink very dirty Clean heatsink

Incorrect mounting position Change mounting position

OH3 x053 Motor temperature

is higher than the

value set in the

controller

Motor too hot because of excessive

current or frequent and too long

acceleration

Check drive dimensioning

NO KTY is connected to X8 Connect KTY or switch off monitoring

(C0583 = 3)

OH4 x054 Heatsink

temperature is

higher than the

value set in C0122

Ambient temperature T

u

>40°Cor

50 °C.

z Allow controller to cool and ensure

better ventilation

z Check ambient temperature in the

control cabinet

Heatsink very dirty Clean heatsink

Incorrect mounting position Change mounting position

The value entered in C0122 is too low Enterhighervalue

OH7 x057 Motor temperature

is higher than the

value set in C0121

Motor too hot because of excessive

current or frequent and too long

acceleration

Check drive dimensioning

NO KTY is connected to X8 Connect KTY or switch off monitoring

(C0584 = 3)

The value entered in C0121 is too low Enterhighervalue

OH8 x058 PTC at terminals

T1, T2 indicates

motor overheating

Motor too hot because of excessive

current or frequent and too long

acceleration

Check drive dimensioning

Terminals T1, T2 are not assigned Connect PTC or thermostat or switch off

monitoring (C0585=3)

OU x020 Overvoltage in t he

DC bus

Braking energy is too high. The DC-bus

voltage is higher than set in C0173.

z Use a braking unit or regenerative

module

z When using the braking units 935x,

check the settings of the switching

thresholds (see Operating

Instructions for 9350 braking unit)

z In case of parallel connection of 935x

braking units, check the settings for

master and slave (see Operating

Instructions for 9350 braking unit)

z If possible prolong the braking ramp

(C0013, C0105)

PEr x074 Program fault An error has been detected in the

program run. The parameter set 1 is

loaded automatically. All parameter

data which have been changed before

but not saved will get lost.

Contact Lenze

PI x079 Initialisation error z A fault was detected during transfer

of parameter set between the

controllers

z Parameter set does not match the

controller

Correct parameter set

Loading...

Loading...