Installation

3-7

Part 1128350_02

E 2020 Nordson Corporation

Compressed Air

Toachievemaximumhotmeltoutput,themeltermustbeconnectedtoanair

supply that is capable of providing 6.2 bar (90 psi) of dry, non-lubricated air.

The actual pres sure required for the melter to support your manufacturing

process will depend on such factors a s the type of hot melt and applicator

you are using and the required dimensions of the hot melt bead.

NOTE: The operating air pressure range for the melter is 0.69 to 6.2 bar

(10 to 90 psi). Operating the melter with air pressure less than the minimum

may cause the pump to function erratically.

Air consumption during operation:

Depending on the type of pump being used, follow these specifications for air

consumption:

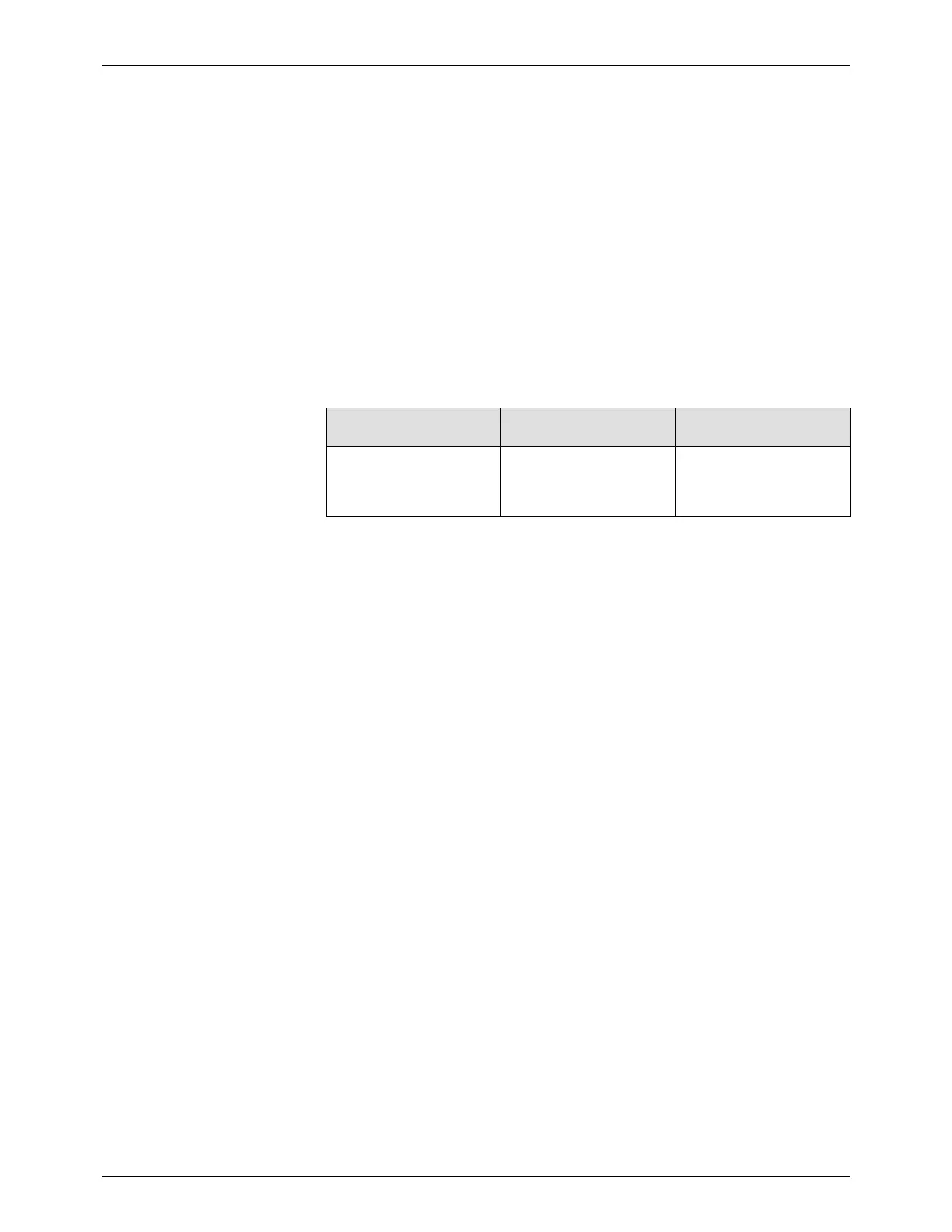

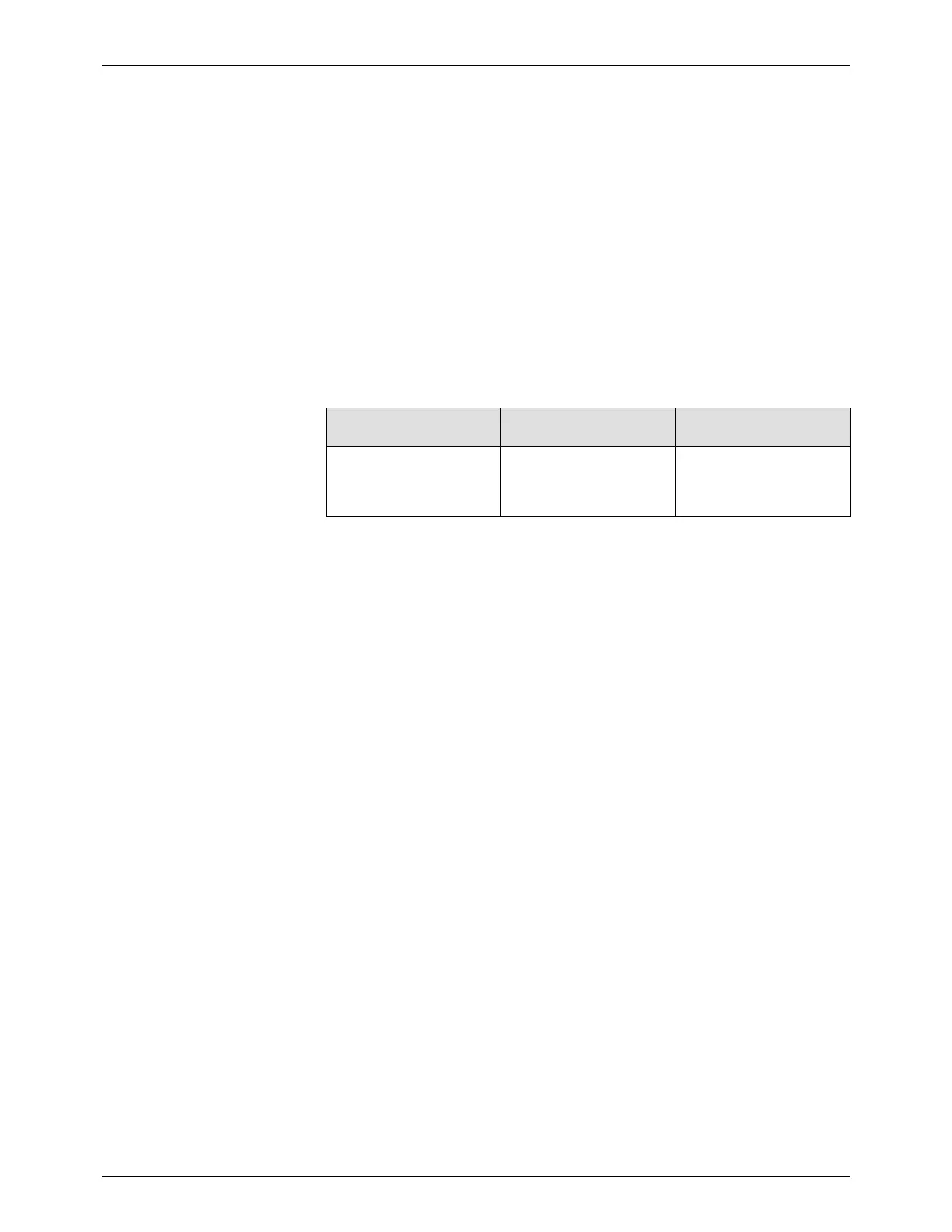

Standard Double-Acting

High-output

Double-Acting

Single-Acting

2.0SCFMat60psiand

1.2 lb/min

(56 l/min at 4.1 bar and

0.54 kg/min output)

3.5SCFMat60psiand

2 lb/min output

(100 l/min at 4.1 bar and

0.91 kg/min output)

4.7SCFMat60psiand

maximum output

(133 l/min at 4.1 bar and

maximum output)

Air consumption with fill system by transfer rate:

S 17 SCFM at 3.4 bar (50 psi) to transfer 105 kg/hr (232 lb/hr) with

a4mhoseata4mrise

S 22 SCFM at 4.1 bar (60 psi) to transfer 113 kg/hr (248 lb/hr) with

a9mhoseata4mrise

S 30SCFMat6.2bar(90psi)totransfer91kg/hr(200lb/hr)withan

18mhoseata4mrise

S Average: 1.3 SCFM for a complete system [melter, 4 m transfer hose,

4.1 bar (60 psi)] operating at 11 kg/hr (25 lbs/hr) adhesive output

NOTE: Nordson recommends that an isolation valve be installed in the plant

airsupplylinejustbeforethemelterforsafetyandmaintenancepurposes.

Loading...

Loading...