Adjustments—455/A2/B2

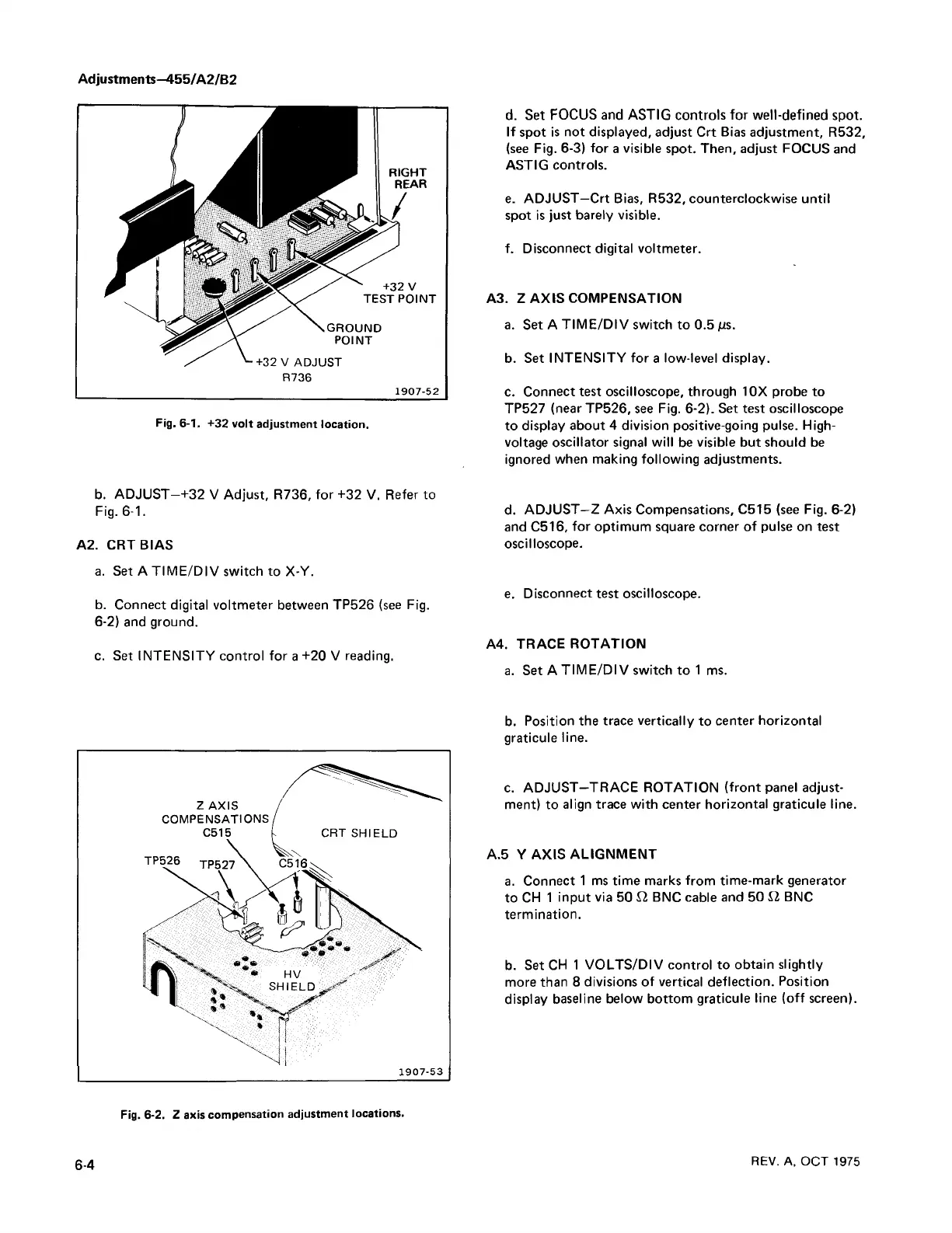

b. ADJUST—+32 V Adjust, R736, for +32 V. Refer to

Fig. 6-1.

A2. CRT BIAS

a. Set A TIME/DIV switch to X-Y.

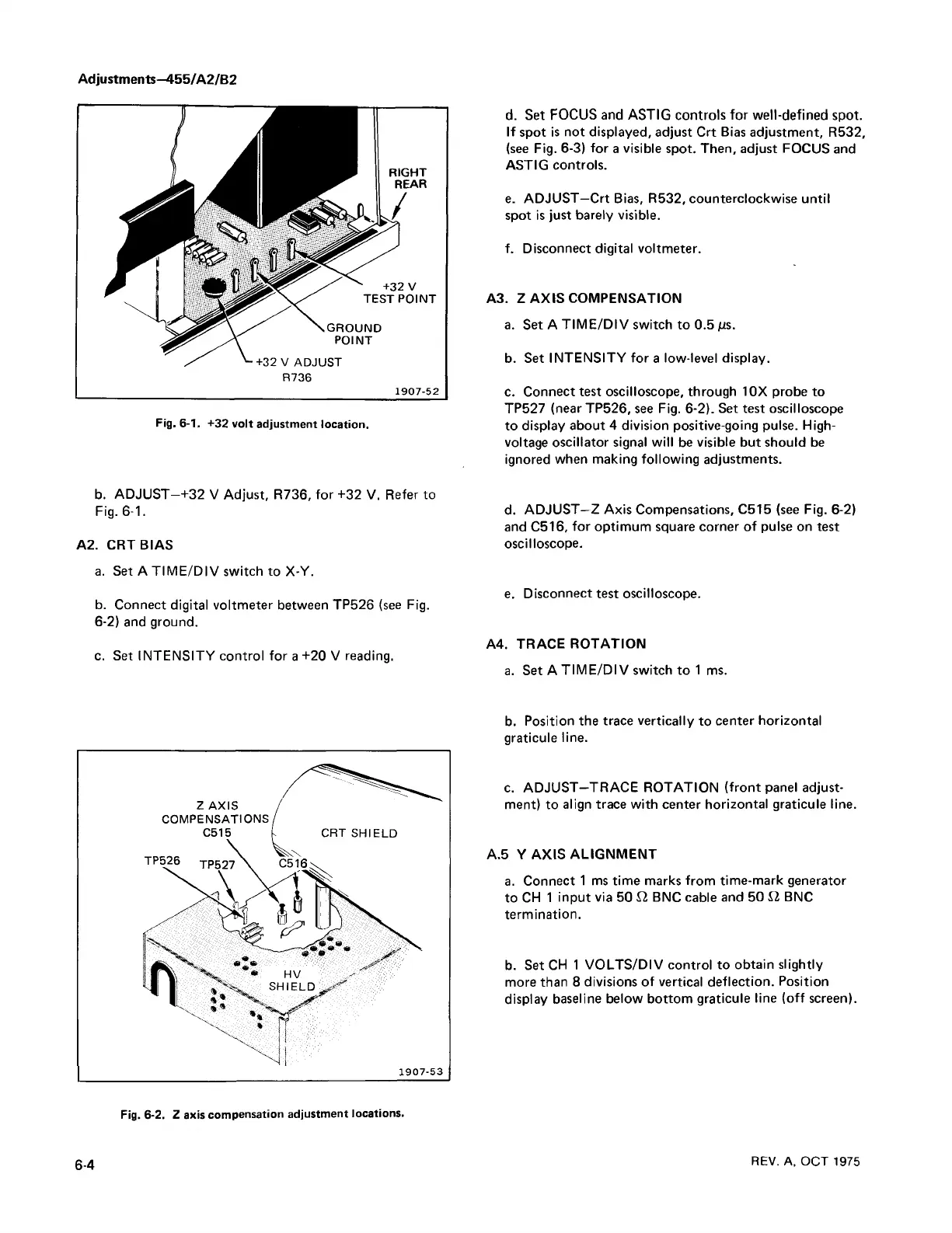

b. Connect digital voltmeter between TP526 (see Fig.

6-2) and ground.

c. Set INTENSITY control for a +20 V reading.

d. Set FOCUS and ASTIG controls for well-defined spot.

If spot is not displayed, adjust Crt Bias adjustment, R532,

(see Fig. 6-3) for a visible spot. Then, adjust FOCUS and

ASTIG controls.

e. ADJUST—Crt Bias, R532, counterclockwise until

spot is just barely visible.

f. Disconnect digital voltmeter.

A3. Z AXIS COMPENSATION

a. Set A TIME/DIV switch to 0.5 /is.

b. Set INTENSITY for a low-level display.

c. Connect test oscilloscope, through 10X probe to

TP527 (near TP526, see Fig. 6-2). Set test oscilloscope

to display about 4 division positive-going pulse. High-

voltage oscillator signal will be visible but should be

ignored when making following adjustments.

d. ADJUST—Z Axis Compensations, C515 (see Fig. 6-2)

and C516, for optimum square corner of pulse on test

oscilloscope.

e. Disconnect test oscilloscope.

A4. TRACE ROTATION

a. Set A TIM E/DIV switch to 1 ms.

b. Position the trace vertically to center horizontal

graticule line.

c. ADJUST—TRACE ROTATION (front panel adjust

ment) to align trace with center horizontal graticule line.

A.5 Y AXIS ALIGNMENT

a. Connect 1 ms time marks from time-mark generator

to CH 1 input via 50 12 BNC cable and 50 12 BNC

termination.

b. Set CH 1 VOLTS/DIV control to obtain slightly

more than 8 divisions of vertical deflection. Position

display baseline below bottom graticule line (off screen).

6-4

REV. A, OC T 1975

Fig. 6-2. Z axis compensation adjustment locations.

Loading...

Loading...