Vertiv | SmartAisle2 | User Manual 113

Operation & Display Panel

Chapter 3: Operation & Display Panel

In this chapter, the SmartAisle2 product including power before checking, power, system debugging and shutdown

will be explained in detail.

3.1. Checks prior to Start

The following checklist needs to be screened through to confirm if all the following items and parameters are

met:

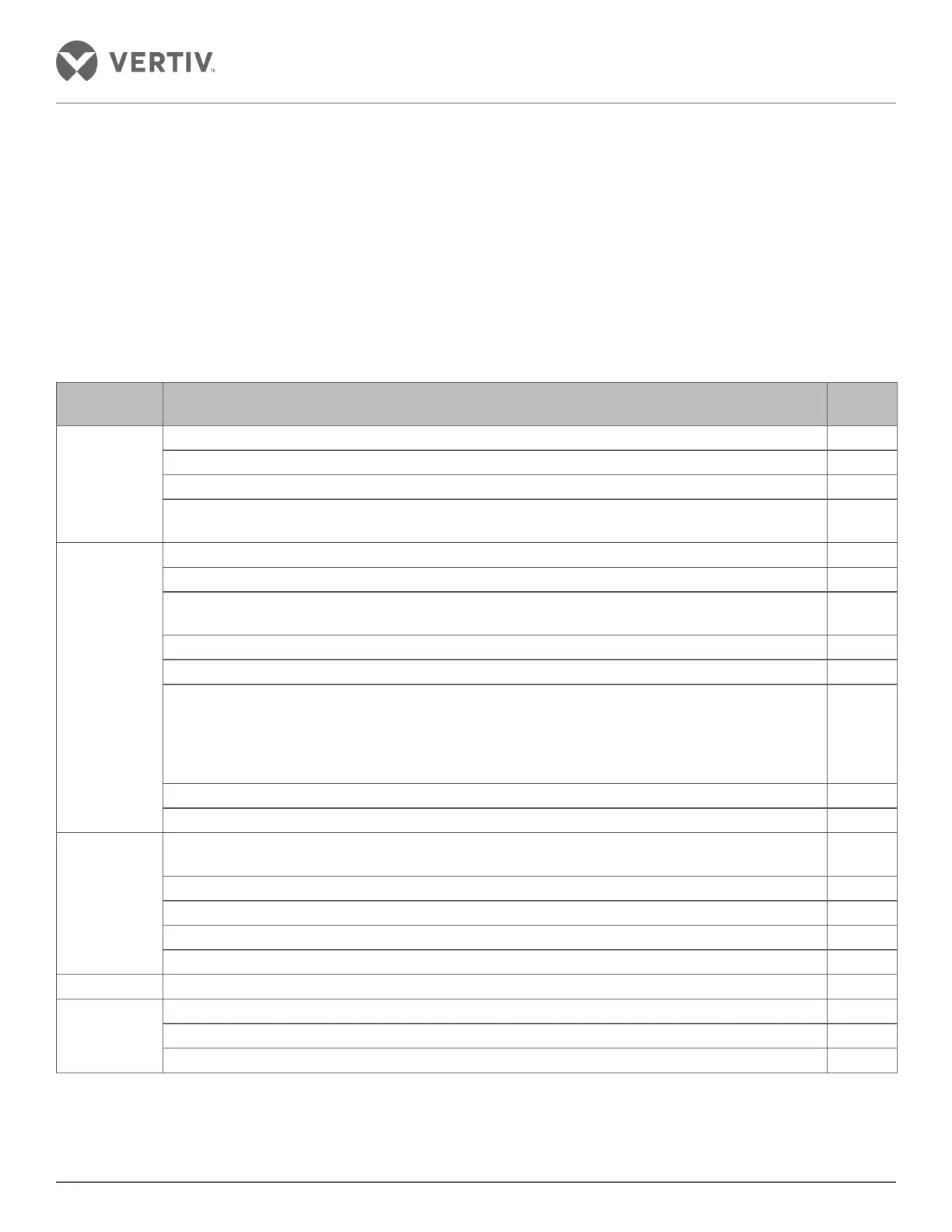

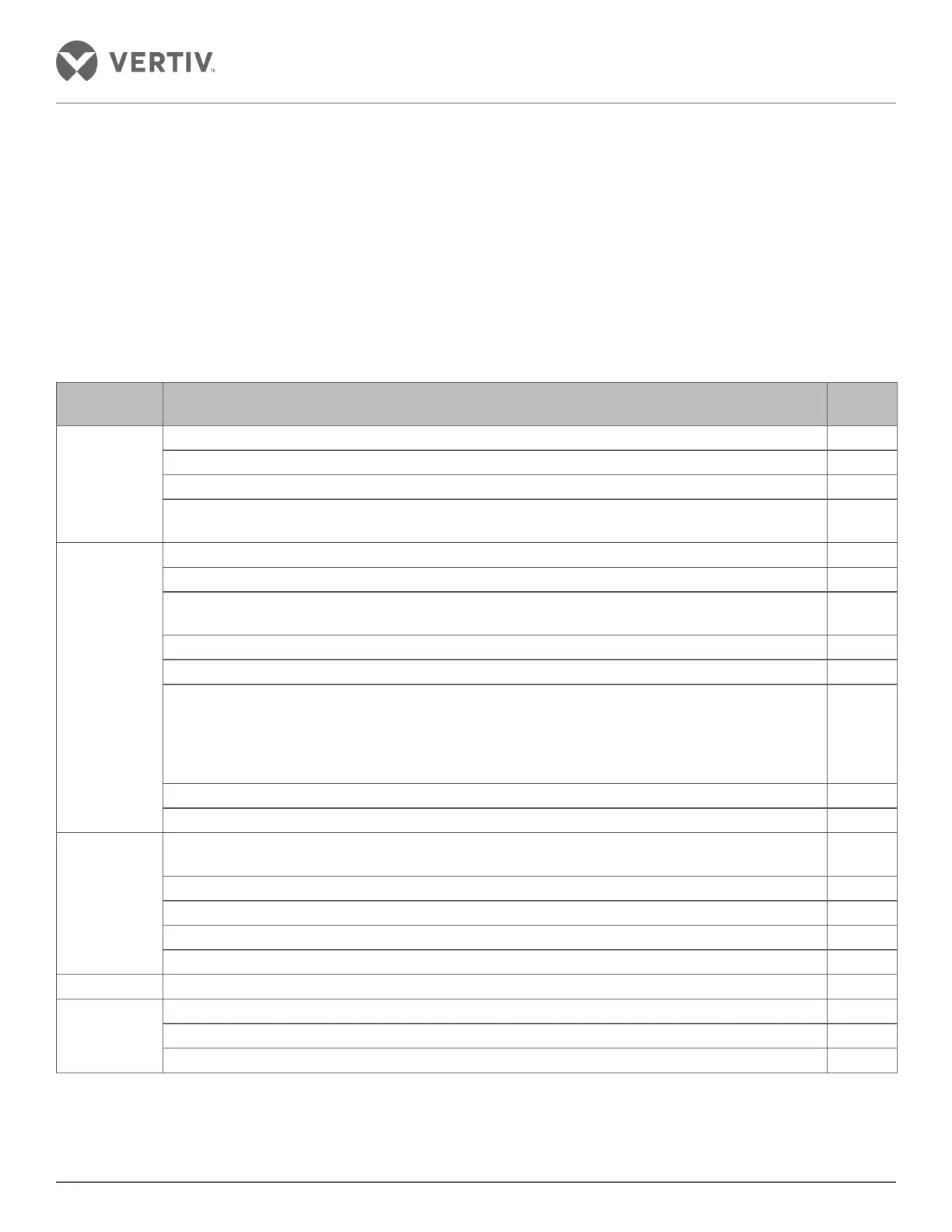

Table 3-1 Checklist prior to Start

Types of

parameters

Checklist items

Test

result

Mechanical

All cables, circuit connectors tightened, no loosening of the fastening screw

And base building has been a reliable connection

Fasteners for transportation have been removed

After installation is complete, or debris inside the device have been removed around (e.g.,

shipping materials, construction materials, tools, etc.)

Cooling

Follow the instructions on the label at the valve, opening all the valves in the refrigerant circuit

The cooling pipe system has been qualified pressure leak test and confirm

The humidification system for drainage pipe system and is firmly connected to the material in

accordance with claim leak

Ensure proper refrigerant charge

Compressor plus tropical warm-up has been more than 12 hours

If located above the room temperature and 18 °C has a certain heat load. If not provided, preferably

by using other heating means or manual operation of the unit itself and force the adjacent heater

equipment (sure to follow the method of operation “Liebert CRV + Series User Manual precision

air conditioning air”), while preheating to the room environment, to ensure heat load necessary

debugging

Confirmation level switch cable is connected and the float rod may work level

Outdoor air-cooled condenser power isolation switch has been closed

Supply and

distribution

Measured with a multi-meter voltage feed line is normal, and the same equipment nameplate

rated voltage

The system does not open electrical circuit, short circuit

Verify that all electrical wiring or control properly tighten all electrical control connectors

Each sub-closing operation switch, each switch test the mechanical properties of normal

Industrial rack PDU male female connector installed properly

Illumination Lighting controller power is properly connected

Electric door

Line resistance and no bump manual door

Cable lashing rails in the firm, cannot be involved in the drive gears, belts

Remove metallic debris from the rail

Loading...

Loading...