OM 25-3503 us – Edition 4.1 * 2503_3503b510.fm 5-5

Maintenance

Collect the fuel/water mixture as it drains with a suitable container and dispose

of it in an environmentally friendly manner.

5.4 Engine lubrication system

If the engine oil level is too low or if an oil change is overdue, this can cause

Engine damage and loss of output!

• Have the oil changed by a Wacker Neuson service center

– see chapter 5.17 Maintenance plan (overview) on page 5-38 (Tier III) or –

see chapter Maintenance plan (Tier IV) on page 5-43 (Tier IV)

Checking the oil level

Information!

Check the oil level once a day.

We recommend checking it before starting the engine. After stopping a warm

engine, wait at least 5 minutes before checking.

☞ Proceed as follows:

•Park the machine on level ground

•Stop the engine!

•Raise the control lever base

•Let the engine cool down

•Open the engine cover

•Clean the area around the oil dipstick with a lint-free cloth

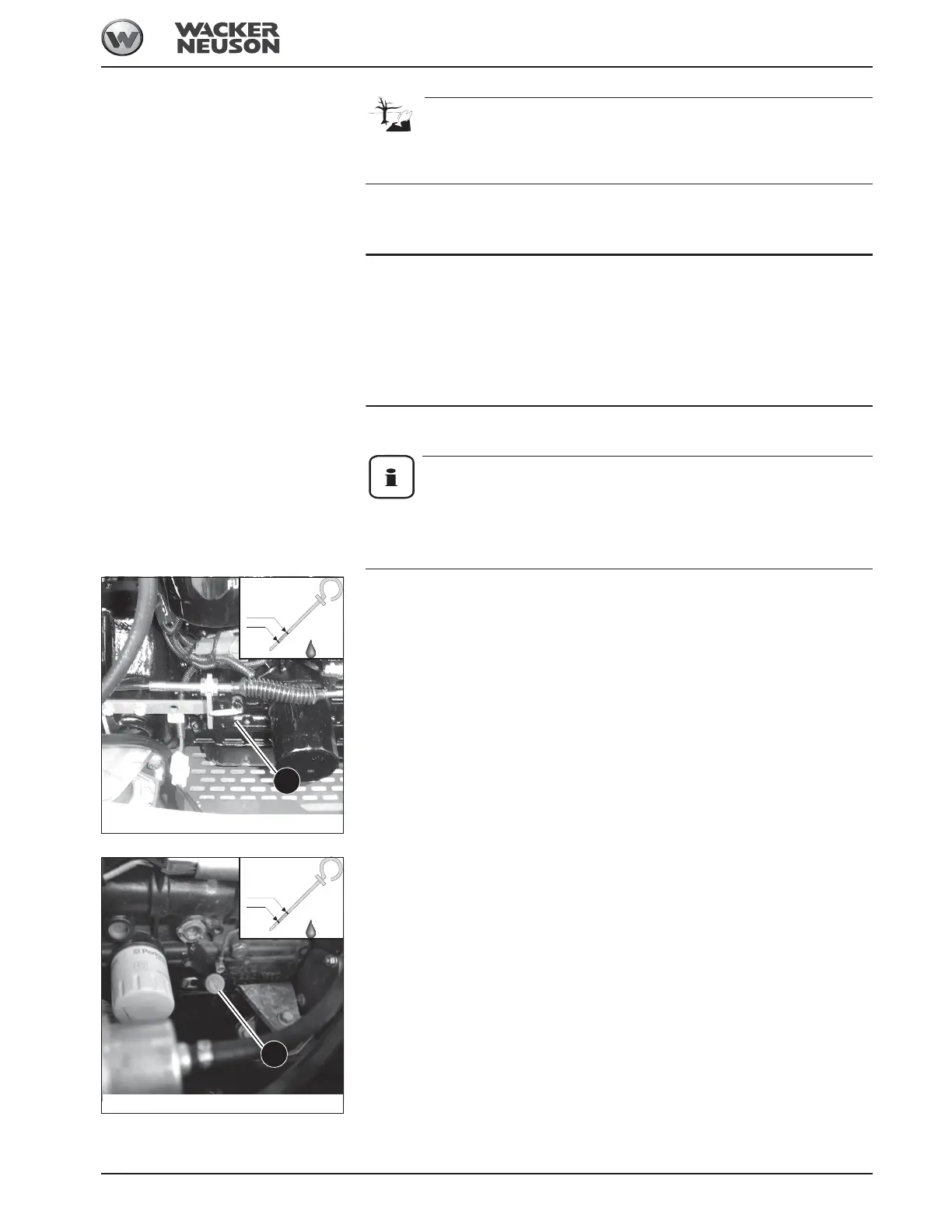

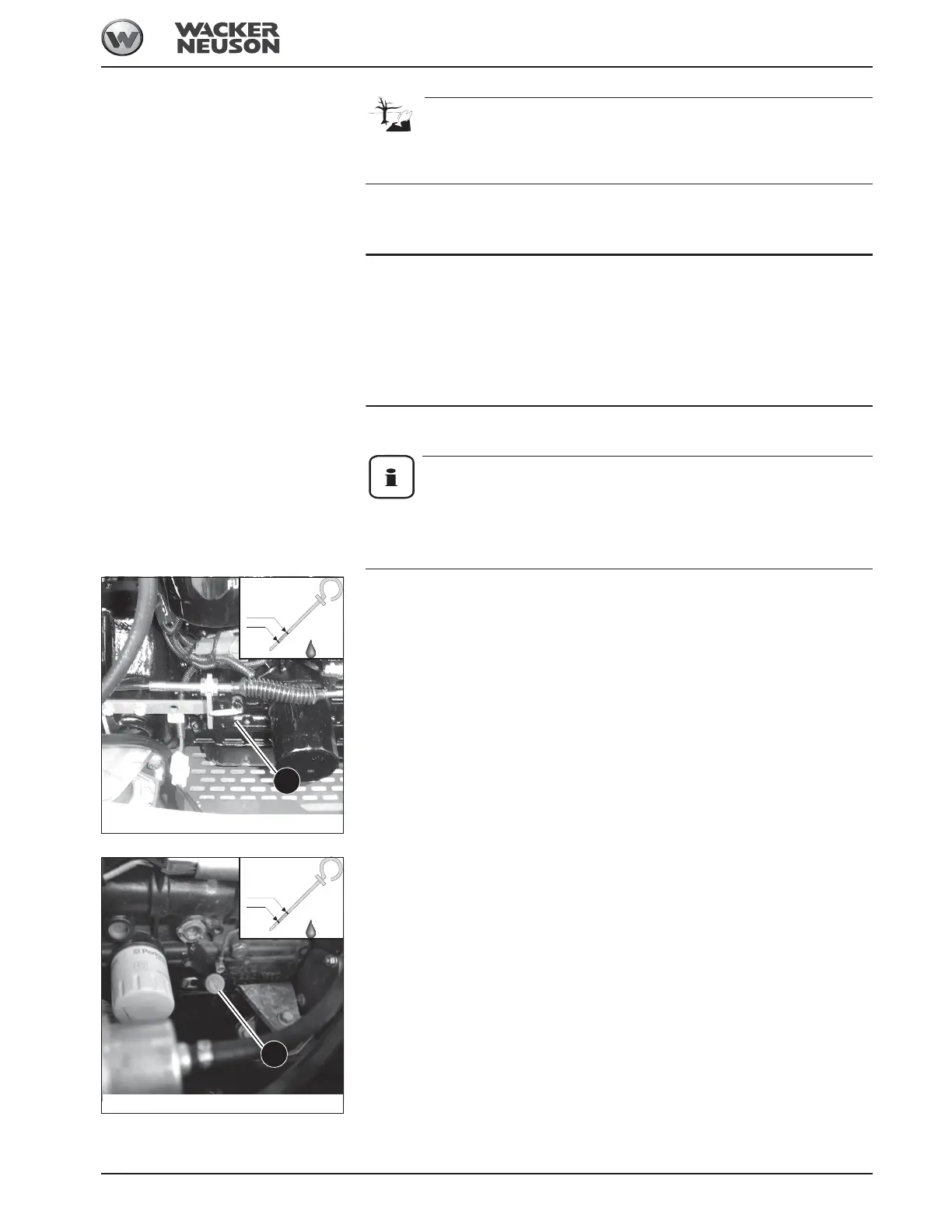

•Oil dipstick A (Tier III) or B (Tier IV)

☞ Pull it out

☞ Wipe it with a lint-free cloth

☞ Push it back in as far as possible

☞ Withdraw it and read off the oil level

☞ However if necessary, add oil at the latest when the oil reaches the MIN mark on the oil

dipstick A or B

Fig. 267: Checking the oil level

Fig. 268: Checking the oil level

Loading...

Loading...