5-20 OM 25-3503 us – Edition 4.1 * * 2503_3503b530.fm

Maintenance

Steel track (option)

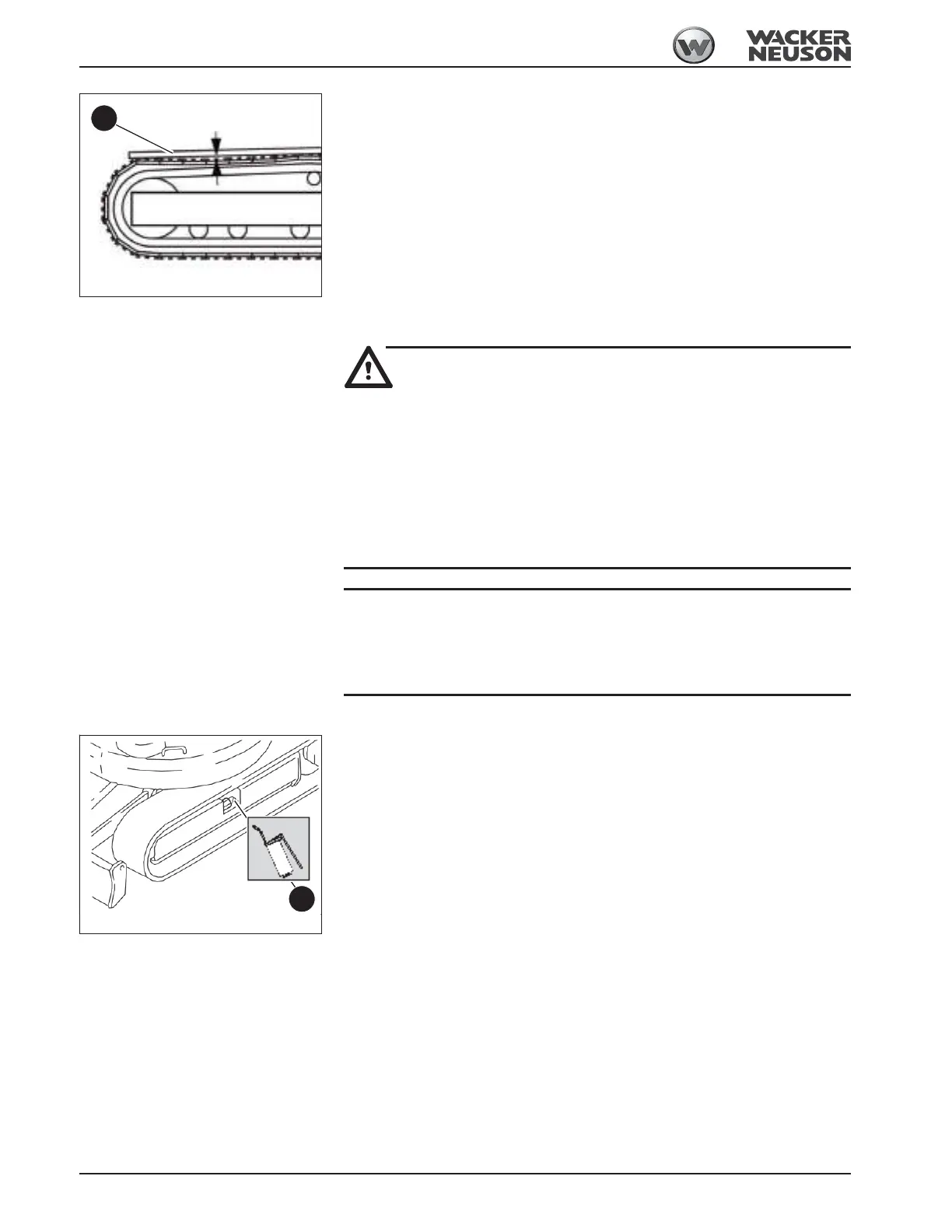

•Place a measuring rod A across the highest points of the track.

•Adjust the correct track tension if the play between the track roller and the

track is not 20 – 25 mm (0.8 - 1 in).

Setting the tracks

Risk of lubricant escaping under high pressure!

Can cause serious injury or death.

• Do not loosen and unscrew the lubricating valve by more than one turn.

• Only the lubricating valve may be loosened.

• Keep your face away from the lubricating valve connection.

➥ Contact a Wacker Neuson service center if this does not reduce track

tension.

Excessive tension of the tracks causes serious damage to the cylinder and the

track.

• Tighten the tracks only up to the prescribed measuring distance

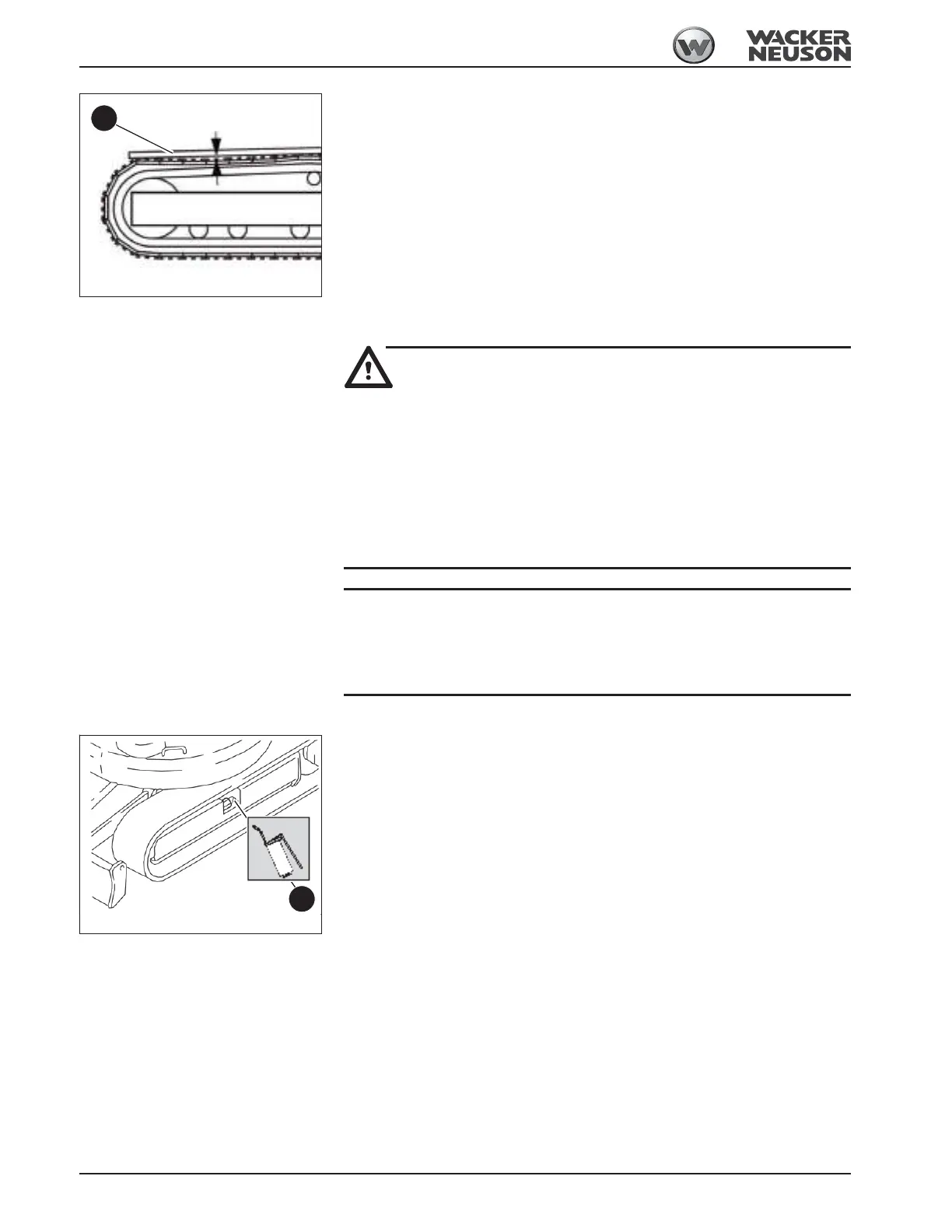

Tightening the tracks

☞ Inject grease with the pump through lubricating valve A

☞ Check the tension is correct by starting the engine, letting it run at idling speed and

slowly performing forward and reverse machine travel and switching it off again

☞ Check the tension of the tracks again

➥ If it is not correct:

☞ Adjust again

☞ Should the track still be slack after injecting more grease, replace the track or the seal

in the cylinder. Contact a Wacker Neuson dealer in this case.

Fig. 285: Checking steel track tension

0.8 – 1 in

20 – 25 mm

A

Fig. 286: Tightening the tracks

A

Loading...

Loading...