JOHNSON CONTROLS

166

SECTION 9 - MAINTENANCE

Form 201.47-ICOM1

Issue date: 17/11/2022

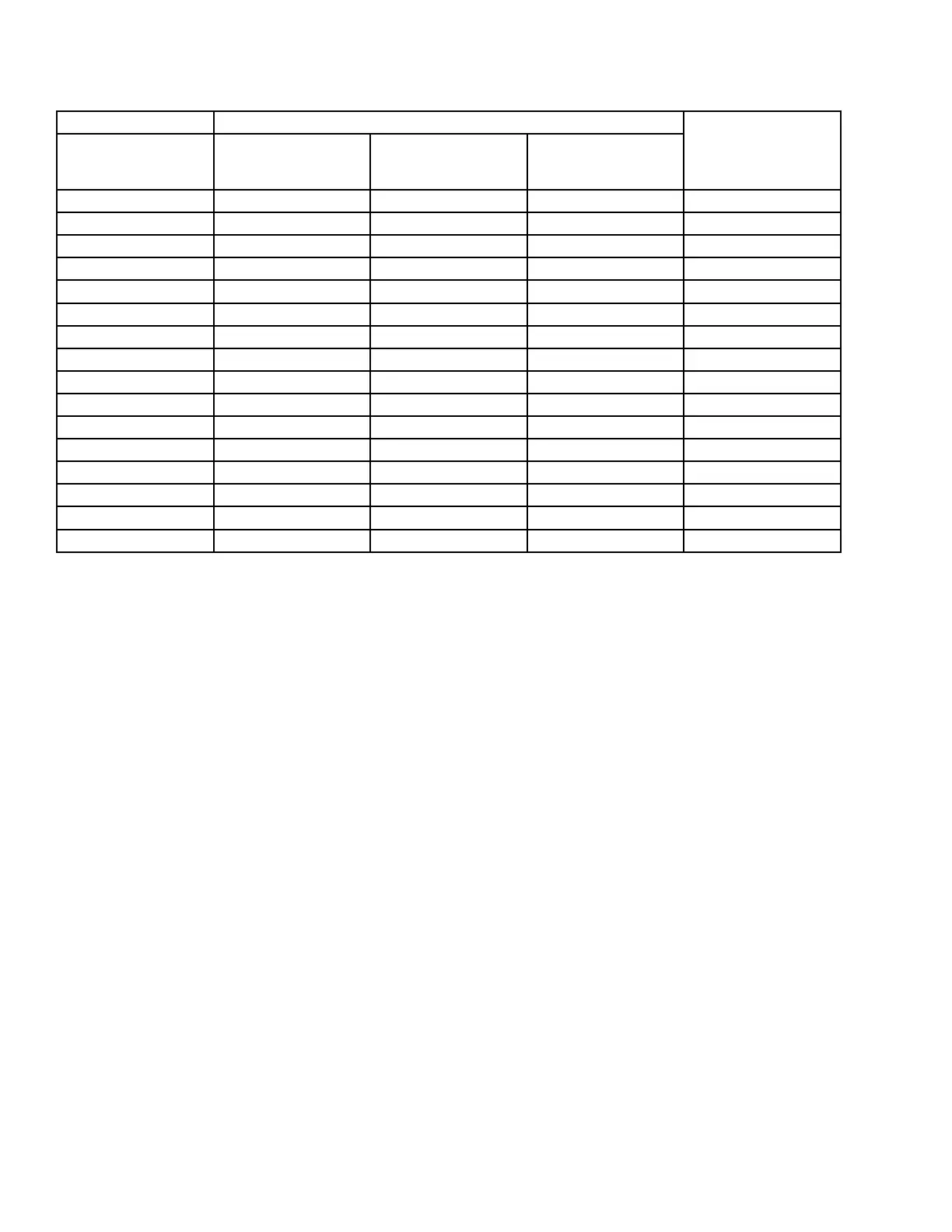

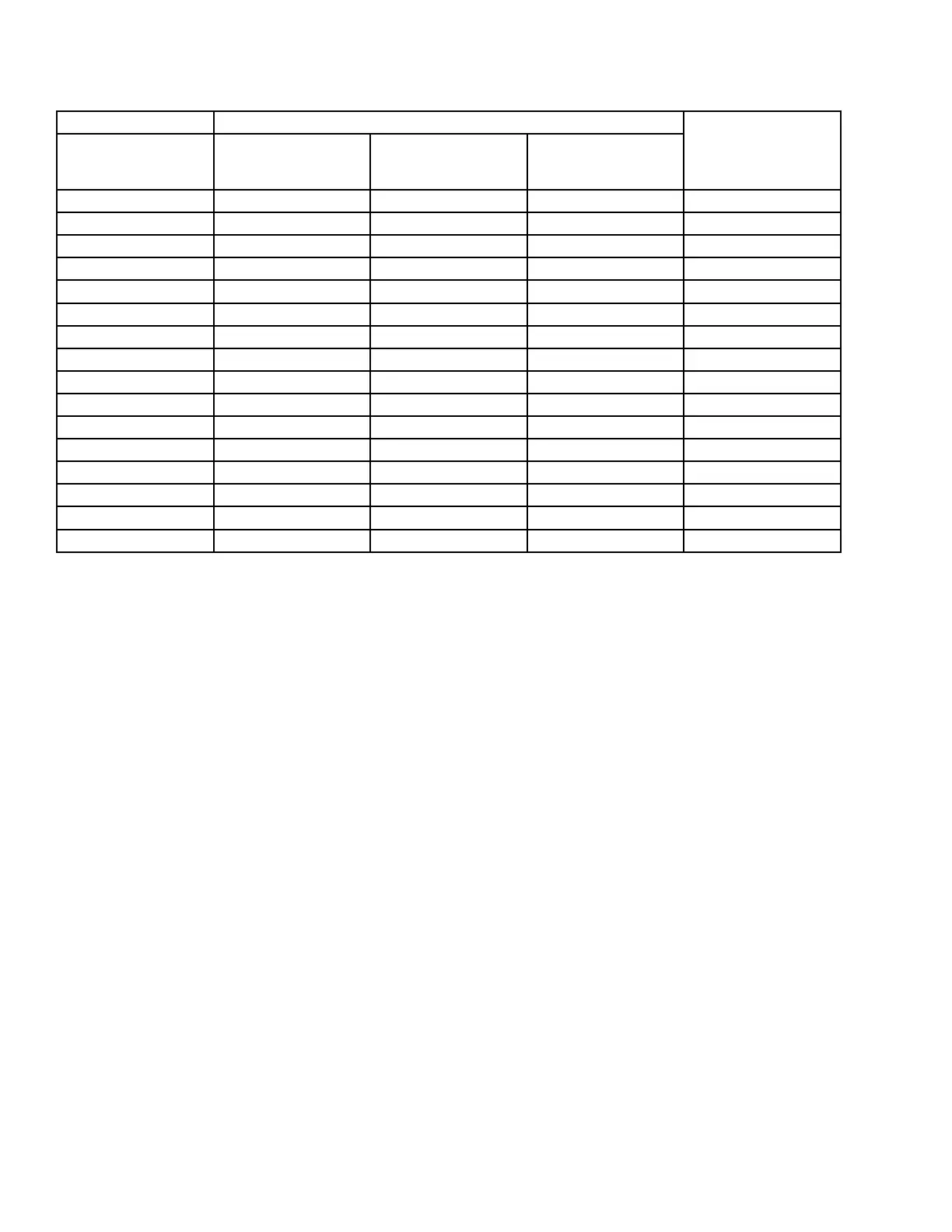

Gauge Absolute

Boiling temperatures

of water, ⁰F

Inches of mercury

(Hg) below one

standard atmosphere

psia Millimeters of

mercury (Hg)

Microns

0 in. 14.6960 760.00 760,000 212

10.240 in. 9.6290 500.00 500,000 192

22.050 in. 3.8650 200.00 200,000 151

25.980 in. 1.9350 100.00 100,000 124

27.950 in. 0.9680 50.00 50,000 101

28.940 in. 0.4810 25.00 25,000 78

29.530 in. 0.1920 10.00 10,000 52

29.670 in. 0.1220 6.30 6,300 40

29.720 in. 0.0990 5.00 5,000 35

29.842 in. 0.0390 2.00 2,000 15

29.882 in. 0.0190 1.00 1,000 1

29.901 in. 0.0100 0.50 500 –11

29.917 in. 0.0020 0.10 100 –38

29.919 in. 0.0010 0.05 50 –50

29.9206 in. 0.0002 0.01 10 –70

29.921 in. 0 0 0

Note:

• One standard atmosphere = 14.696 psia = 760 mm Hg absolute pressure at 32°F = 29.921 in. Hg absolute at 32°F

• psig = pound per square inch gauge pressure = pressure above atmosphere

• psia = pound per square inch absolute pressure = sum of gauge plus atmospheric pressure

• Shell volume = L*π * r2= (Length in feet)*( 3.1416)*(radius squared) = cubic feet

To keep the units consistent, round the length and radius to the nearest tenth of a foot.

• μm = Micron

Table 28 - System pressures

Dehydration

To make sure that there is confidence in the vacuum

decay related to moisture boiling off, only perform the

dehydration process after the system has been thor-

oughly leak checked. The dehydration process is only

needed if the following occurs:

1. The nitrogen holding charge on shipments has

been lost.

2. The system has been open to the atmosphere for

any length of time.

3. Tube leaks have introduced moisture to the refrig-

erant circuit.

4. Indications of moisture contamination have ap-

peared in any of the sight glasses Dehydration of

a refrigerant system can be obtained by the evacu-

ation method because the water present in the

system reacts much as a refrigerant would. How-

ever, the vacuum pressure in the system cannot

always be pulled down to a point where its satura-

tion temperature is considerably below that of the

equipment room temperature due to low ambient

room conditions and other factors. As a result, you

warm water through at least one vessel to raise

the vessel internal temperature. This ensures that

the water, so that a large percentage of it can be

removed by the vacuum pump.

The length of time necessary for the dehydration of a

system depends on the size or volume of the system,

Loading...

Loading...