JOHNSON CONTROLS

170

SECTION 9 - MAINTENANCE

Form 201.47-ICOM1

Issue date: 17/11/2022

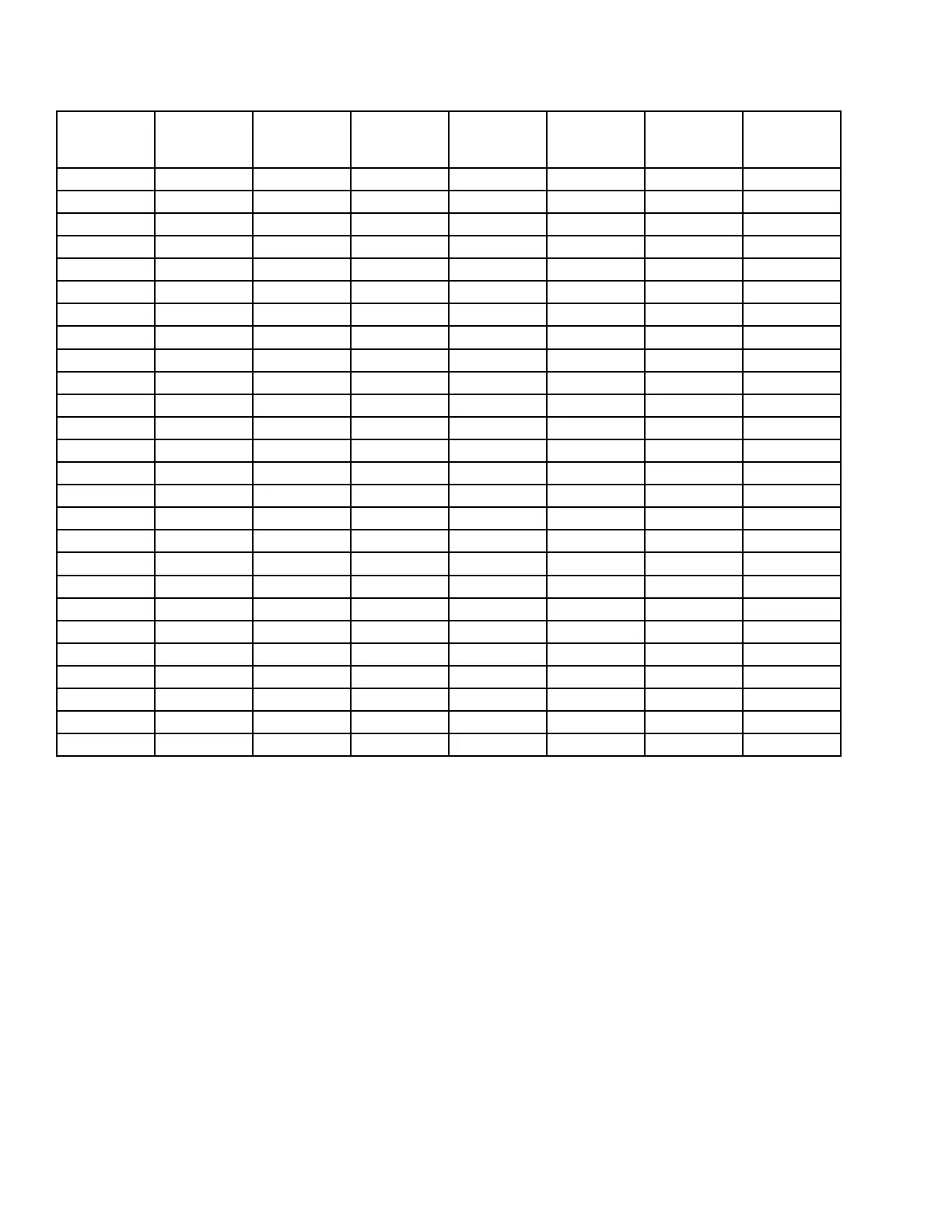

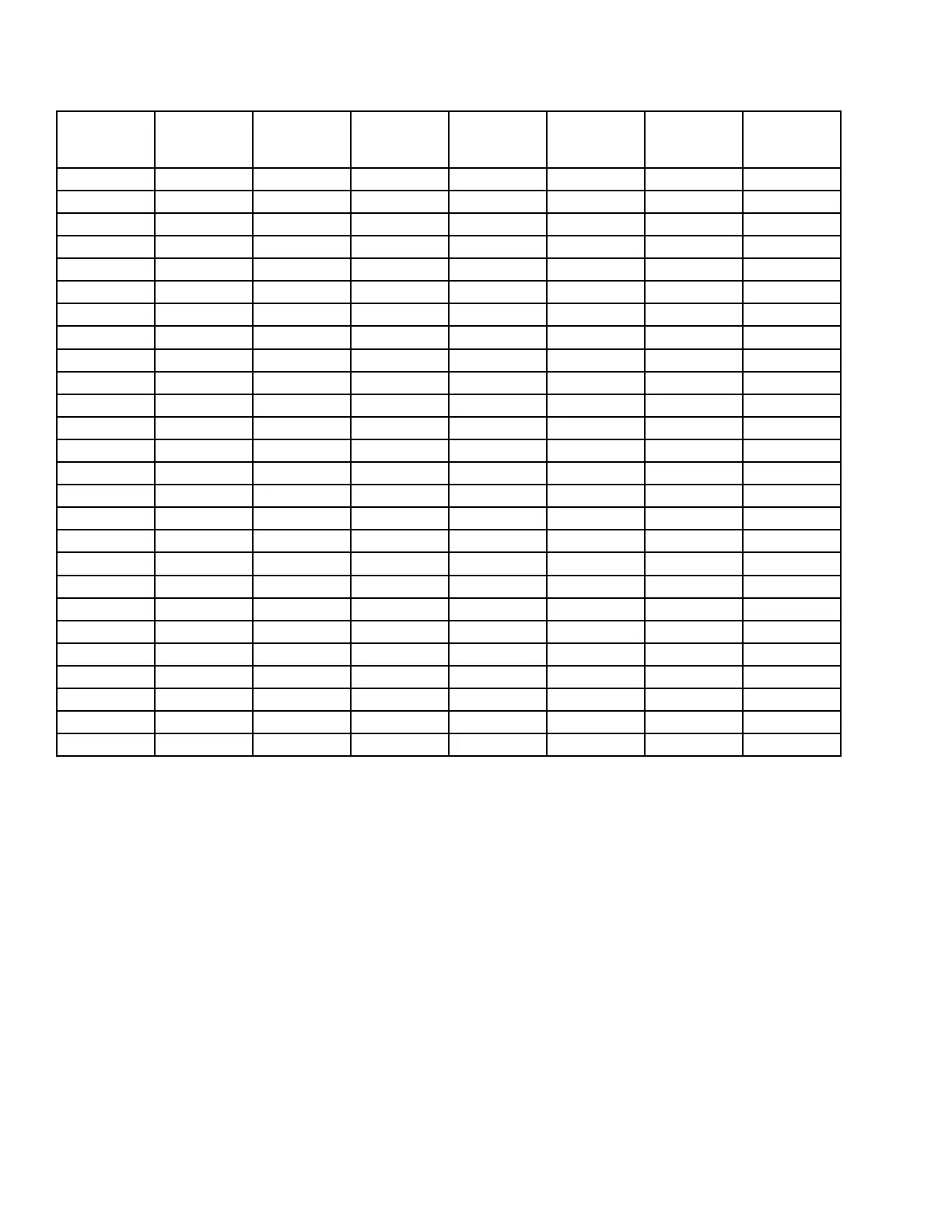

Table 30 - R-513A pressure to saturated temperature conversion

Pressure

psig (bar)

Temperature

average

0

F(

0

C)

Pressure

psig (bar)

Temperature

average

0

F(

0

C)

Pressure

psig (bar)

Temperature

average

0

F(

0

C)

Pressure

psig (bar)

Temperature

average

0

F(

0

C)

0.0 (0.0) -20.5 (-29.1) 130 (8.96) 99.3 (37.4) 260 (17.93) 146.7 (63.8) 390 (26.89) 179.1 (81.7)

5.0 (0.34) -8.4 (-22.4) 135 (9.31) 101.6 (38.7) 265 (18.27) 148.1 (64.5) 395 (27.23) 180.2 (82.3)

10.0 (0.69) 1.4 (-17.0) 140 (9.65) 103.9 (39.9) 270 (18.62) 149.6 (65.3) 400 (27.58) 181.2 (82.9)

15.0 (1.03) 9.8 (-12.3) 145 (10.0) 106.1 (41.2) 275 (18.96) 151.0 (66.1) 405 (27.92) 182.3 (83.5)

20.0 (1.38) 17.2 (-8.2) 150 (10.34) 108.3 (42.4) 280 (19.31) 152.4 (66.9) 410 (28.27) 183.3 (84.1)

25.0 (1.72) 23.8 (-4.5) 155 (10.69) 110.4 (43.5) 285 (19.65) 153.7 (67.6) 415 (28.61) 184.3 (84.6)

30.0 (2.07) 29.8 (-1.2) 160 (11.03) 112.4 (44.7) 290 (19.99) 155.1 (68.4) 420 (28.96) 185.4 (85.2)

35.0 (2.41) 35.3 (1.8) 165 (11.38) 114.5 (45.8) 295 (20.34) 156.4 (69.1) 425 (29.30) 186.4 (85.8)

40.0 (2.76) 40.4 (4.6) 170 (11.72) 116.4 (46.9) 300 (20.68) 157.7 (69.8) 430 (29.65) 187.4 (86.3)

45.0 (3.10) 45.1 (7.3) 175 (12.07) 118.4 (48.0) 305 (21.03) 159.0 (70.6) 435 (29.99) 188.4 (86.9)

50.0 (3.45) 49.5 (9.7) 180 (12.41) 120.3 (49.1) 310 (21.37) 160.3 (71.3) 440 (30.34) 189.4 (87.4)

55.0 (3.79) 53.7 (12.1) 185 (12.76) 122.2 (50.1) 315 (21.72) 161.6 (72.0) 445 (30.68) 190.3 (87.4)

60.0 (4.14) 57.7 (14.2) 190 (13.10) 124.0 (51.1) 320 (22.06) 162.9 (72.7) 450 (31.03) 191.3 (88.5)

65.0 (4.48) 61.5 (16.4) 195 (13.44) 125.8 (52.1) 325 (22.41) 164.1 (73.4) 455 (31.37) 192.2 (89.0)

70.0 (4.83) 65.1 (18.4) 200 (13.79) 127.6 (53.1) 330 (22.75) 165.3 (74.1) 460 (31.72) 193.2 (89.6)

75.0 (5.17) 68.5 (20.3) 205 (14.13) 129.3 (54.1) 335 (23.10) 166.6 (74.8) 465 (32.06) 194.1 (90.1)

80.0 (5.52) 71.9 (21.2) 210 (14.48) 131.0 (55.0) 340 (23.44) 167.8 (75.4) 470 (32.41) 195.1 (90.6)

85.0 (5.86) 75.0 (23.9) 215 (14.82) 132.7 (55.9) 345 (23.79) 168.9 (76.1) 475 (32.75) 196.0 (91.1)

90.0 (6.21) 78.1 (25.6) 220 (15.17) 134.3 (56.8) 350 (24.13) 170.1 (76.7) 480 (33.09) 196.9 (91.6)

95.0 (6.55) 81.0 (27.2) 225 (15.51) 136.0 (57.8) 355 (24.48) 171.3 (77.4) 485 (33.44) 197.8 (92.1)

100.0 (6.89) 83.9 (28.8) 230 (15.86) 137.6 (58.7) 360 (24.82) 172.4 (78.0) 490 (33.78) 198.7 (92.6)

105.0 (7.24) 86.6 (30.3) 235 (16.20) 139.1 (59.5) 365 (25.17) 173.6 (78.7) 495 (34.13) 199.6 (93.1)

110.0 (7.58) 89.3 (31.8) 240 (16.55) 140.7 (60.4) 370 (25.51) 174.7 (79.3) 500 (34.47) 200.4 (93.6)

115.0 (7.93) 91.9 (33.3) 245 (16.89) 142.2 (61.2) 375 (25.86) 175.8 (79.9) 505 (34.82) 201.3 (94.1)

120.0 (8.27) 94.4 (34.7) 250 (17.24) 143.7 (62.1) 380 (26.20) 176.9 (80.5)

125.0 (8.62) 96.9 (36.5) 255 (17.58) 145.2 (62.9) 385 (26.54) 178.0 (81.1)

Before charging, establish the starting weight for the

refrigerant cylinder. When the chiller has been vapor

charged to the appropriate saturation pressure, you

might need to use a refrigerant pump to draw vapor

from the chiller and discharge it to the vapor connec-

tion of the refrigerant cylinder. This helps to create a

pressure differential for pushing the refrigerant liquid

from the cylinder to the chiller.

While charging, take every precaution to prevent air

from entering the system. Create a suitable charging

connection from new copper tubing or correctly select-

ed flexible charging hoses. Fit this charging connection

between the system charging valve and the fitting on

the charging drum.

This connection must be as short as possible but long

enough to provide sufficient flexibility for changing

drums. It must also contain a tee fitting with a valve

that can serve as a connection point to a vacuum pump

to evacuate the charging lines.

The charging connection must be evacuated each time

the lines are disconnected for changing cylinders or

any of the components of the charging process.

The charging line must also contain a sight glass.

When liquid charging is performed, the sight glass can

be monitored to determine when the liquid is no longer

being transferred to the chiller.

The refrigerant charge is specified for each chiller

model on the unit data plate or in the factory order form

(FOF) that is provided for every new sale. Charge the

chiller based on the amount specified in the FOF less

10%. For example, for a chiller that requires 500# of

refrigerant, the initial refrigerant charge is 450#, 500

- 50 = 450. This allows room to trim the charge as out-

lined in Checking and trimming the refrigerant charge

on page 172 .

Loading...

Loading...