SECTION 4 - INSTALLATION

JOHNSON CONTROLS

33

Form 201.47-ICOM1

Issue date: 17/11/2022

4

Water treatment

The unit performance provided in the Design Guide

is based on a fouling factor of 0.018 m/hr °C/kW

(0.0001 fthr°F/Btu). Dirt, scale, grease and certain

types of water treatment will adversely affect the heat

exchanger surfaces and therefore the unit performance.

Foreign matter in the water systems can increase the

heat exchanger pressure drop, reducing the flow rate and

causing potential damage to the heat exchanger tubes.

Aerated, brackish or salt water is not recommended

for use in the water systems. Johnson Controls recom-

mends that a water treatment specialist must be con-

sulted to determine whether the proposed water com-

position adversely affects the evaporator materials of

carbon steel and copper. The pH value of the water

flowing through the evaporator must be kept in a range

between 7 and 8.5.

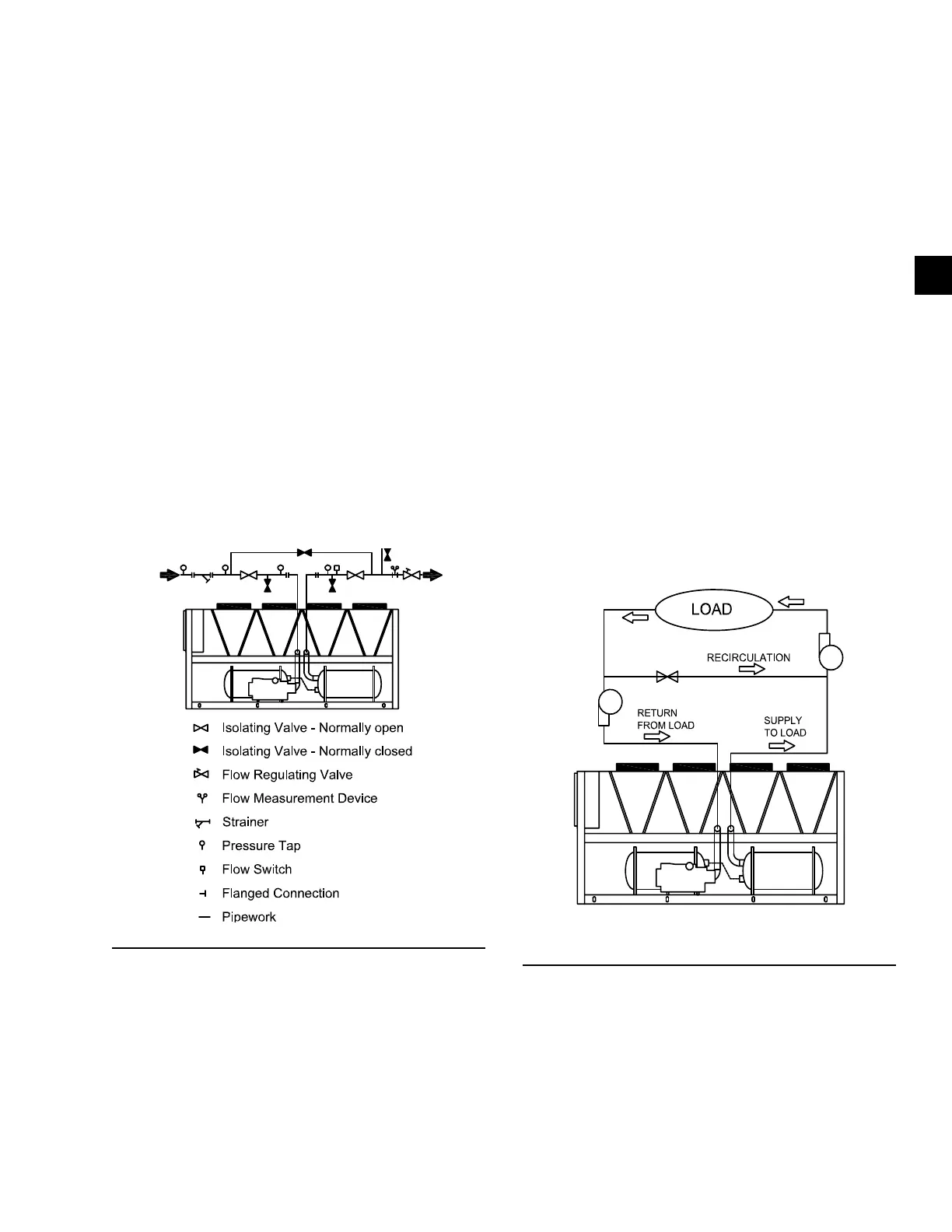

Pipework arrangement

The following is a suggested piping arrangement for

single unit installations.

Figure 10 - Pipework arrangement

LD15151

Minimum water volume

It is good practice to include as much water volume

as possible in a chilled water loop. This increases the

thermal mass and flywheel effect within the system

(that is, the more; the better) which in turn promotes

stable water temperature control and increases reliabil-

ity by reducing compressor cycling.

For air conditioning applications, a minimum of 3

gallons/ton is required. with a preferred gallon/ton

ratio to be within the 5 to 8 range. For process applica-

tions, a minimum of 6 gallons/ton ratio is required with

preference towards a range of 7 to 11. Install a tank or

increase pipe sizes to provide sufficient water volume.

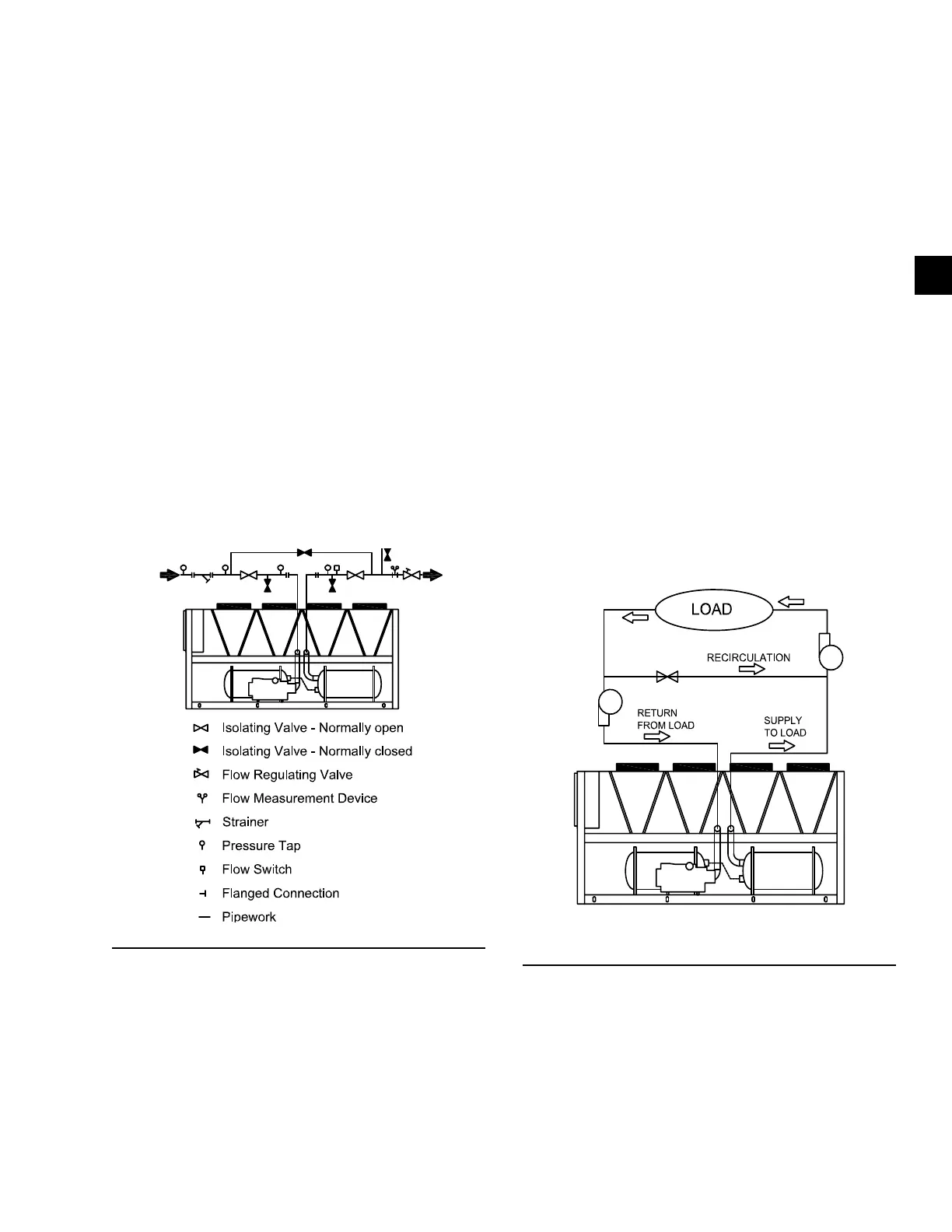

Leaving water temperature out of range

The YVAA chiller line has a maximum leaving water

temperature of 21.1°C (70°F). Where process applica-

tions require a chilled water temperature higher than

what the chiller provides, a simple piping change can

remove the problem. By using a mixture of chiller-

cooled water and returning process water, the chilled

water entering the process can be held at the required

temperature. A tank can also be used to meet high

leaving water temperature requirements.

Each YVAA evaporator has a minimum and maximum

flow rate. Some process applications require a flow

rate that is out of range for the evaporator. In those ap-

plications, a piping change can remove the problem.

In applications where the required flow rate is less than

the evaporator’s minimum allowable, the chilled water

can be recirculated to the chiller.

Figure 11 - Leaving water temperature out of range

suggested layout

LD15049

Loading...

Loading...