SECTION 9 - MAINTENANCE

JOHNSON CONTROLS

177

Form 201.47-ICOM1

Issue date: 17/11/2022

9

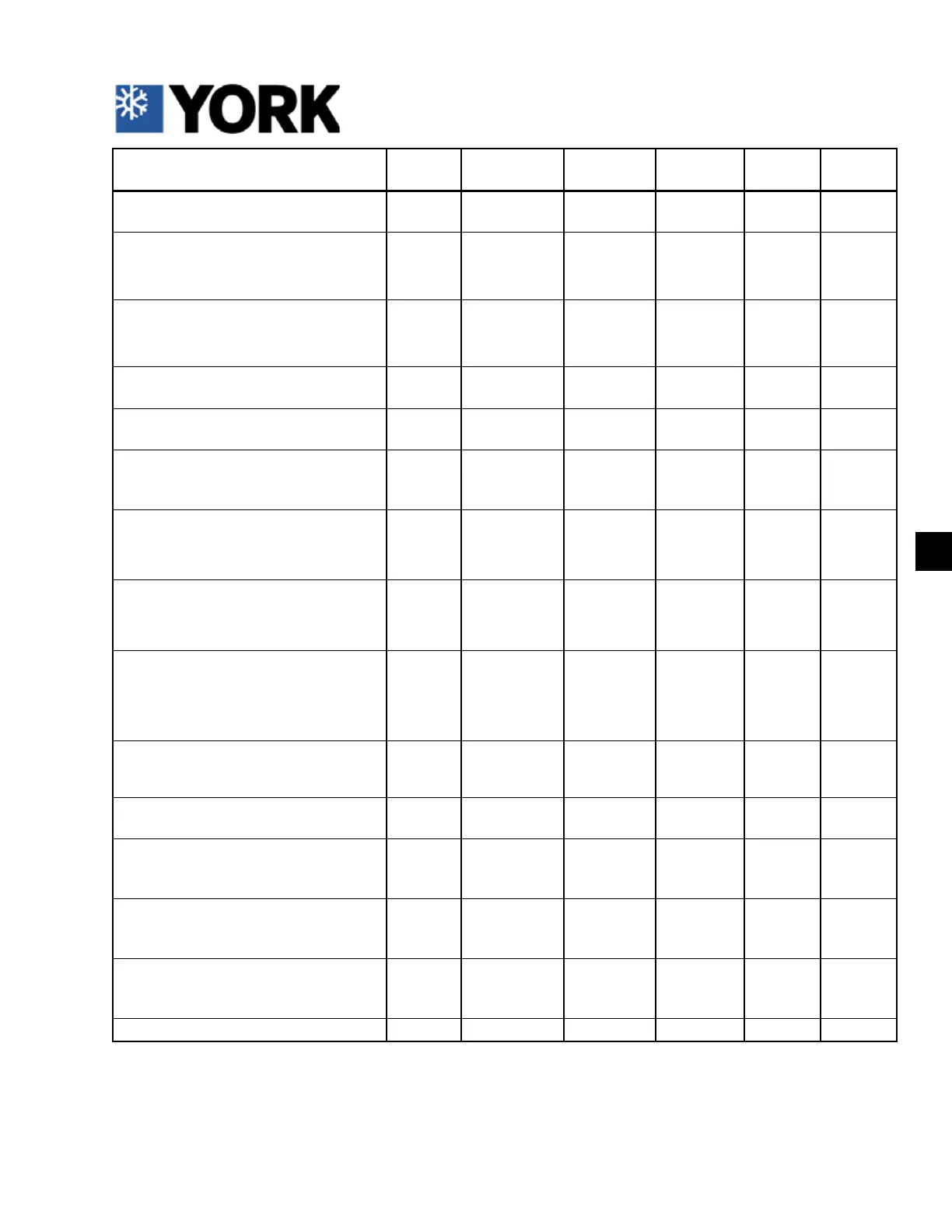

Procedure Weekly Quarterly

Semi-

annually

Annually

Every 5

years

Every *

hours

Check Oil Level in Oil Separator Sight

Glass.

X

Check Liquid Line Sight Glass/Moisture

Indicator.

X

Check refrigerant level in the Evaporator

Sight Glass while running full load for 10

to 15 minutes.

X

Record System Operating Temperatures

& Pressures.

X

Check Condenser Coils for dirt / debris

and clean as necessary.

X

Check Programmable Operating

Setpoints and Safety Cutouts. Ensure

they are correct for the application.

X

Check Compressor and Evaporator

Heater operation.

X*** X

Check Suction Isolation Valve operation if

equipped.

X

Check for dirt in the Panel. Check Door

Gasket sealing integrity.

X

**Leak check the Chiller. X

**Sample Compressor Oil, check for Acid,

and replace if necessary.

X

**Disconnect Power Source and Lock

Out. Check tightness of Power Wiring

connections.

X

Check Glycol concentration on Low Temp.

or other applications where freezing may

be a problem.

X

Replace Corrosion Inhibitor pucks (P/N

026-37706-000) inside the Chiller VSD

Cabinet.

X

VSD Glycol Change. X

* Reserved for customer use for any special site requirements.

** This procedure must be performed at the specic time by an industry certied technician who has been

trained and qualied to work on this type of equipment. A record of this procedure be successfully carried out must be maintained on le by the

equipment owner should proof of adequate maintenance be required at a later date for warranty purposes.

*** Chiller controller cannot detect the failure of heaters, all heaters including compressor and evaporator heater need to be checked weekly and

maintained to be operational in subfreezing regions in winter. Weekly maintenance to heaters and with the chilled water pump controlled by unit

controller is recommended and mandatory.

Maintenance requirements for YVAA chillers

Loading...

Loading...