JOHNSON CONTROLS

23

Form 201.47-ICOM1

Issue date: 17/11/2022

3

Section 3 - Rigging, handling, and storage

Lifting weights

Refer to the unit nameplate for unit shipping weight.

Note that weight may vary depending on unit configu-

ration at the time of lifting. See Table 5 on page 66

or Table 6 on page 70 for further information regard-

ing shipping and operating weights.

Delivery and storage

To ensure consistent quality and maximum reliability,

all units are tested and inspected before leaving the

factory. Units are shipped completely assembled

and containing refrigerant under pressure. Units are

shipped without export crating unless crating has been

specified on the Sales Order.

If the unit is to be put into storage, before installation,

the following precautions must be observed:

• The chiller must be blocked so that the base is not

permitted to sag or bow.

• Ensure that all openings, such as water connec-

tions, are securely capped.

• Do not store where exposed to high ambient air

temperatures that may exceed relief valve set-

tings. Refer to Long-Term Storage Requirement

- Field Preparation (Form 50.20-NM7).

• The condensers must be covered to protect the coils

-

ticularly where building work is in progress.

• The unit should be stored in a location where there

is minimal activity in order to limit the risk of ac-

cidental physical damage.

• To prevent inadvertent operation of the pressure

relief devices the unit must not be steam cleaned.

• Inspect the unit periodically during storage.

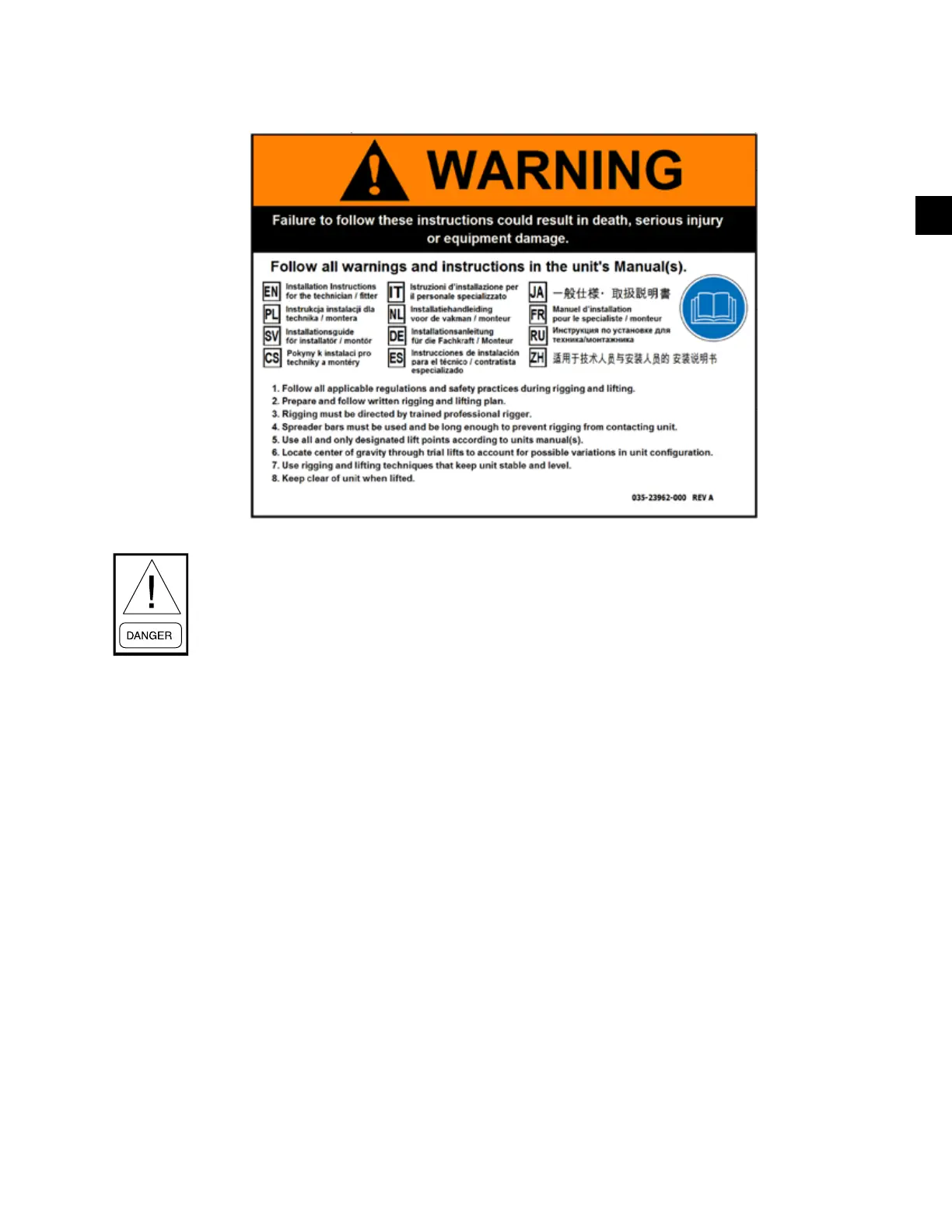

Rigging and lifting must only be done by a professional rigger in accordance with a written

rigging and lifting plan. The most appropriate rigging and lifting method will depend on job specic

factors, such as the rigging equipment available and site needs. Therefore, a professional rigger

must determine the rigging and lifting method to be used, and it is beyond the scope of this manual

to specify rigging and lifting details.

LD19197

Loading...

Loading...