JOHNSON CONTROLS

17

Form 201.47-ICOM1

Issue date: 17/11/2022

SECTION 2 - PRODUCT DESCRIPTION

2

Semi-hermetic YORK twin-screw

compressors

Compressors are direct drive, semi-hermetic and

rotary twin-screw type, including: muffler, temperature

actuated off-cycle heater, IP55 terminal board, and pre-

cision machined cast iron housing.

Reliable suction gas cooled, high efficiency, acces-

sible hermetic compressor motor, full suction gas flow

through mesh screen filter, with inherent internal ther-

mal overload protection and external current overload

on all three phases.

Continuous function, microprocessor controlled,

variable speed drive (VSD) must provide valve-less,

smooth capacity control from 100% down to 10% of

chiller capacity.

In addition, elimination of the slide valve and associ-

ated unloading components has resulted in a 50% re-

duction in compressor moving parts.

Evaporator

The evaporator is a two-circuit, series counterflow

shell and tube, hybrid falling film type heat exchanger.

It contains a balance of flooded and falling film tech-

nology to optimize efficiency, minimize refrigerant

charge, and maintain reliable control. A specifically

designed distribution system provides uniform refrig-

erant flow for optimum performance.

Condenser

The YVAA Style B introduces next-gen 4G microchan-

nel coils to the YORK screw compressor chiller line.

This design allows for bigger flow channels, reducing

refrigerant pressure drop by three to four times and

improving condenser performance. The microchan-

nel maximizes condenser heat transfer, resulting in a

smaller footprint, and reduces refrigerant charge by as

much as 50%.

Each condenser coil is a single piece all aluminum

construction including headers, tubes and fins to avoid

galvanic corrosion due to dissimilar metals. Coils and

headers are brazed as one piece. Integral subcooling

is included. The design working pressure is 375 psig

(25.9 barg).

Multiple, standard low sound, high efficiency, variable

speed drive motor driven fans move air through the

coils. They are dynamically and statically balanced,

direct drive with corrosion-resistant glass fiber rein-

forced composite blades molded into low-noise, full

airfoil cross sections, providing vertical air discharge

from extended orifices for efficiency and low sound.

Fan motors are totally enclosed air-over (TEAO),

squirrel-cage type and current protected. The direct

drive motors feature double-sealed and permanently

lubricated ball bearings, cutting down on mainte-

nance cost over the life of the unit. The chiller is also

equipped with the option of variable speed electroni-

cally commutated (EC) motors to provide extra airflow

across coils with lower power consumption, resulting

in higher efficiencies.

Refrigerant circuit

An independent refrigerant circuit is provided per

compressor. Each circuit uses copper refrigerant pipe

formed on computer controlled bending machines to

reduce the number of brazed joints resulting in a reli-

able and leak resistant system.

• Discharge lines are provided with a manual com-

Accessories and

Options on page 19, for service isolation valve.

• The external oil separators, with no moving parts

and designed for minimum oil carry-over, are

mounted in the discharge line of the compressor.

• Liquid line components include: high absorp-

valve.

• A brazed plate heat exchanger is located in each

-

cy.

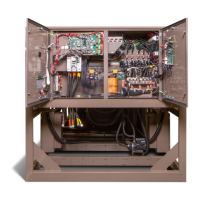

Electrical

Johnson Controls has over 25 years of experience de-

signing variable-speed drives specifically for chiller

applications. The result is an extremely reliable air-

cooled chiller system that offers industry leading ef-

ficiency at real world operating conditions, valve-less

compressor loading/unloading, excellent capacity con-

trol, high power factor and soft start.

Incoming single point power is standard utilizing a

lockable circuit breaker, 115 VAC control transformer,

VSD, fan contactors, ON/OFF unit switch, microcom-

puter keypad and display, Chiller Control and VSD

Logic boards, and relay boards.

Standard design includes IP55 rating, powder painted

steel cabinet with hinged, latched, and gasket sealed

outer doors equipped with wind struts for safer servic-

ing. The panel includes a control display access door so

that display and control features can be accessed with-

Loading...

Loading...