286 Actual signals and parameters

4304 FORCED

OPEN LVL

Defines the speed at brake release. Parameter setting

overrides parameter 4302 BRAKE OPEN LVL setting. After

start, the drive speed is frozen to the set value, until the

motor is magnetized.

The purpose of this parameter is to generate enough start

torque to prevent the motor rotating into the wrong direction

because of the motor load.

0.0 =

NOT SEL

0.0 = NOT SEL

0.0…100.0%

Value as a percentage of the maximum frequency (in scalar

control) or the maximum speed (in vector control). If

parameter value is set to zero, the function is disabled. The

control mode is selected by parameter 9904 MOTOR CTRL

MODE.

1 = 0.1%

4305 BRAKE MAGN

DELAY

Defines motor magnetizing time. After start drive

current/torque/speed is frozen to the value defined by

parameter 4302 BRAKE OPEN LVL or 4304 FORCED

OPEN LVL for the set time.

0 = NOT

SEL

0 = NOT SEL

0…10000 ms

magnetizing time. If parameter value is set to zero, the

function is disabled.

1 = 1 ms

4306 RUNTIME

FREQ LVL

Defines the brake close speed. When frequency falls below

the set level during run, the brake is closed. The brake is re-

opened when the requirements set by parameters

4301…4305 are met.

0.0 =

NOT SEL

0.0 = NOT SEL

0.0…100.0%

Value as a percentage of the maximum frequency (in scalar

control) or the maximum speed (in vector control). If

parameter value is set to zero, the function is disabled. The

control mode is selected by parameter 9904 MOTOR CTRL

MODE.

1 = 0.1%

4307 BRK OPEN

LVL SEL

Selects the torque (in vector control) or current (in scalar

control) applied at brake release.

PAR 4302

PAR 4302 Value of parameter 4302 BRAKE OPEN LVL used. 1

MEMORY Torque value (in vector control) or current value (in scalar

control) saved in parameter 0179 BRAKE TORQ MEM

used.

Useful in applications where initial torque is needed to

prevent unintended movement when the mechanical brake

is released.

2

50 ENCODER Encoder connection.

For more information, see MTAC-01 pulse encoder interface

module user’s manual (3AFE68591091 [English]).

5001 PULSE NR States the number of encoder pulses per one revolution. 1024 ppr

32…16384 ppr Pulse number in pulses per round (ppr) 1 = 1 ppr

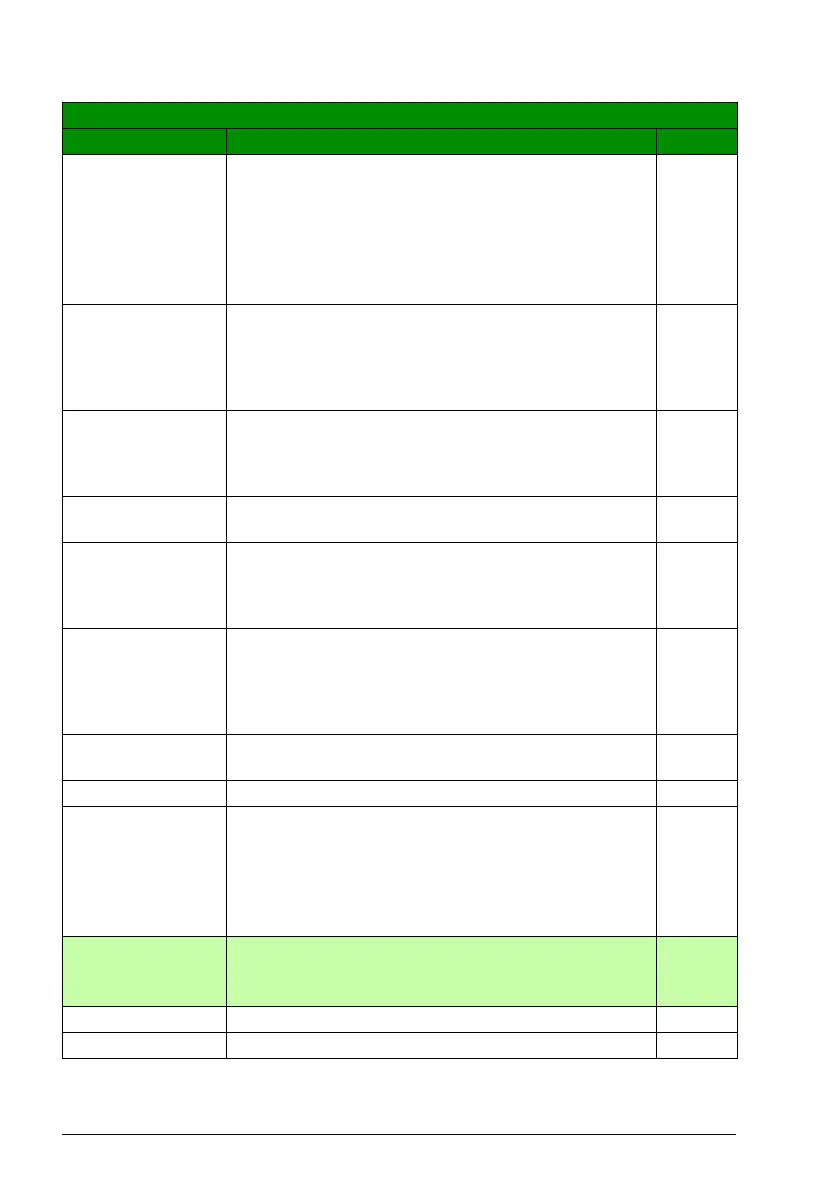

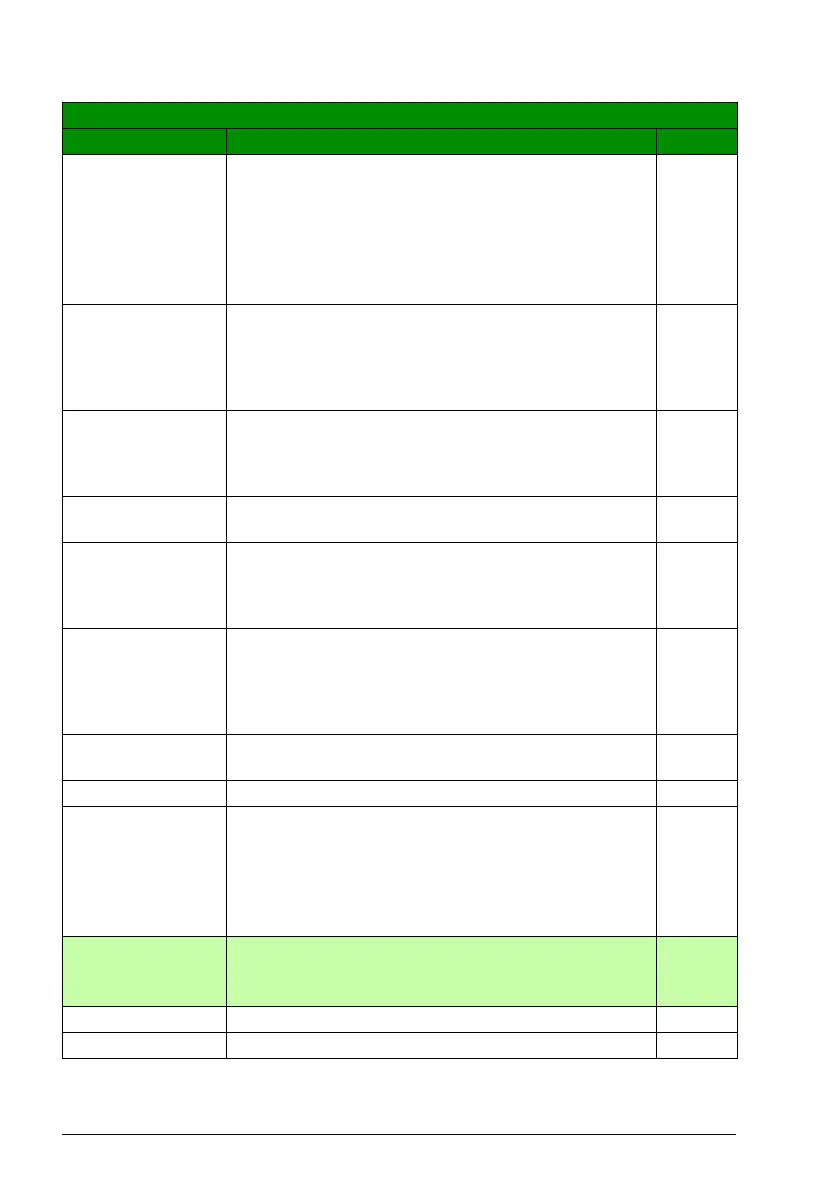

All parameters

No. Name/Value Description Def/FbEq

Loading...

Loading...