9-4 Chapter 9: Inspection and Maintenance 42/24-10 EN Rev. 9

Uras26: Optical Alignment

Definition Optical alignment of the Uras26 analyzer module will minimize asymmetry of the

radiation which falls in through the sample and reference sides of the sample cell.

When should optical

alignment be

performed?

An optical alignment must always be performed

• If the offset drift has fallen below the permissible range (50% of the physical

measurement range)

• After a component (emitter, sample cell, calibration unit /cell, detector) is

installed in or removed from a beam path.

How should optical

alignment be

performed?

Each beam path in the analyzer module must be optically aligned separately. If

there are two detectors in a beam path, the optical alignment should be

performed in the rearmost detector (as seen from the emitter). During an optical

alignment, beam path intensity is varied by means of mechanical apertures and, if

necessary, by turning the emitter case. For this, the system housing must be

opened (see Figure 9-4, page 9-5).

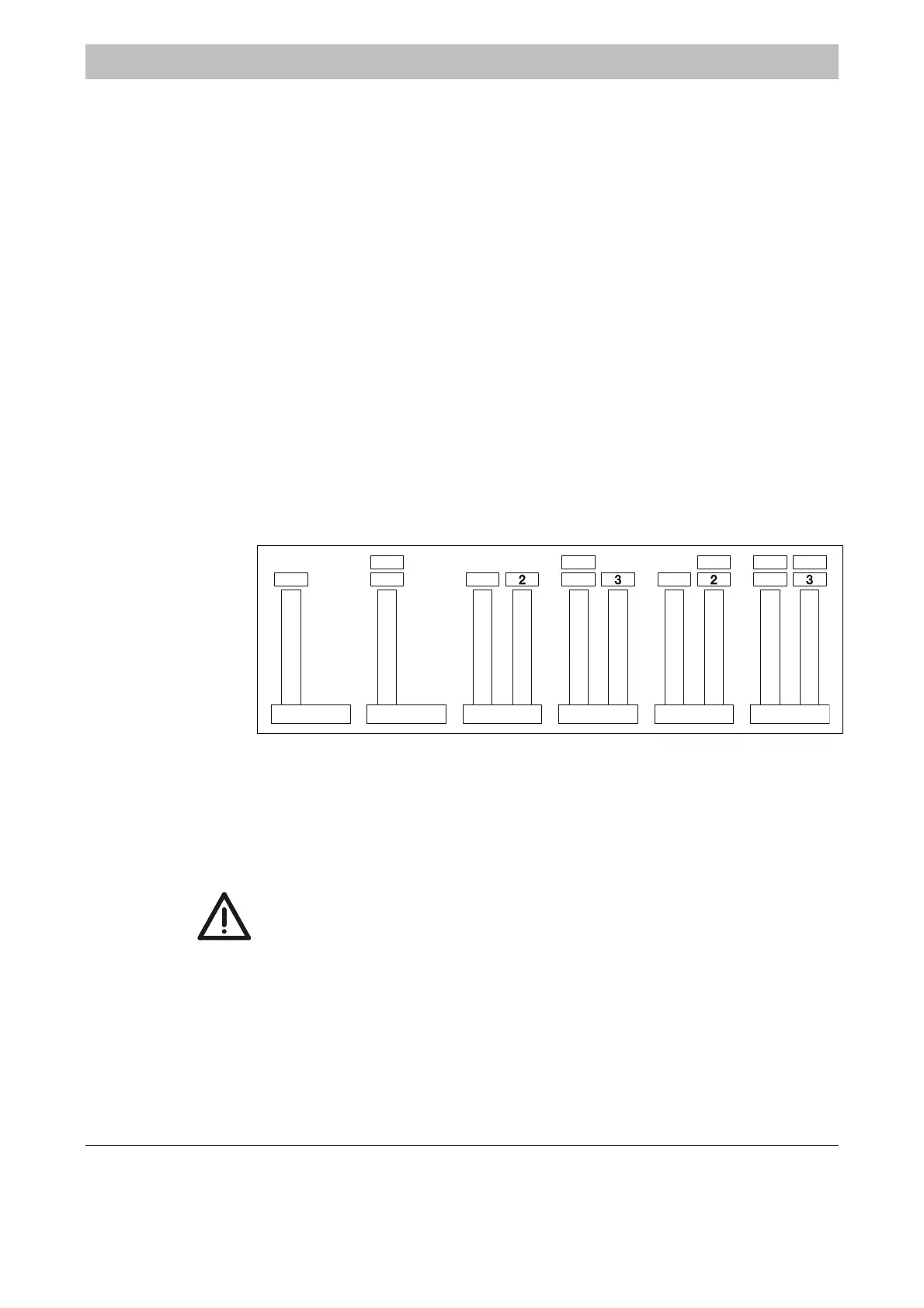

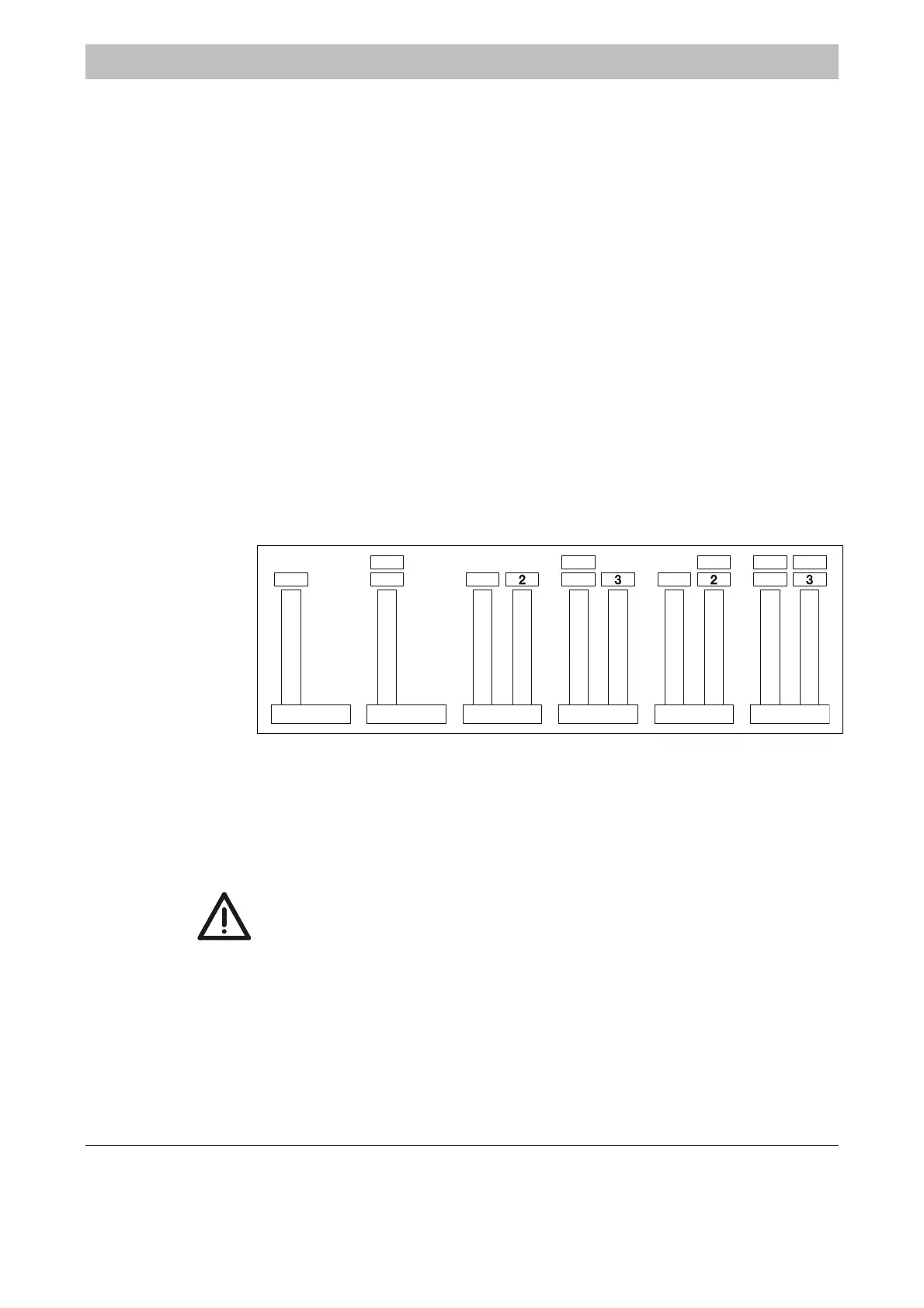

Detector

Arrangement

Figure 9-3 shows the detector layout. Detector numbers correspond to the

numbers assigned to the series of measurement components as shown on the

analyzer module identification plate.

Figure 9-3

Uras26 Analyzer

Module Detector

Numbering

11

2

1 1

2

1

3

1

42

Test Gas During optical alignment the zero gas supply must be turned on.

Emitter Wrench An “emitter wrench” is required to rotate the emitter case (see Figure 9-4, page

9-5). It is affixed to the analyzer module.

CAUTION!

Current-bearing components can be exposed when the covers or parts are

removed, even if this can be done without tools. Current can be present at

some connection points. All work on a gas analyzer that is open and con-

nected to power should only be performed by trained personnel who are

familiar with the risks involved.

Menu Path MENU

→ Maintenance/Test → Analyzer spec. adjustm. →

Optical adjustm.

Continued on next page

Loading...

Loading...