144 Rockwell Automation Publication 1756-UM540E-EN-P - December 2017

Chapter 8 Calibrate the ControlLogix Analog I/O Modules

Difference between

Calibrating an Input Module

and an Output Module

Although the purpose of calibrating analog modules is the same for input and

output modules, to improve the module’s accuracy and repeatability, the

procedures that are involved differs for each:

• When you calibrate input modules, you use current, voltage, or ohms

reference signals to send a signal to the module to calibrate it.

• When you calibrate output modules, you use a digital multimeter (DMM)

to measure the signal that the module is sending out.

To maintain the factory calibration accuracy of your module, we recommend

instrumentation with the specifications listed in Table 23

. A high-resolution

DMM can also be used to adjust a voltage/current calibrating source to its value.

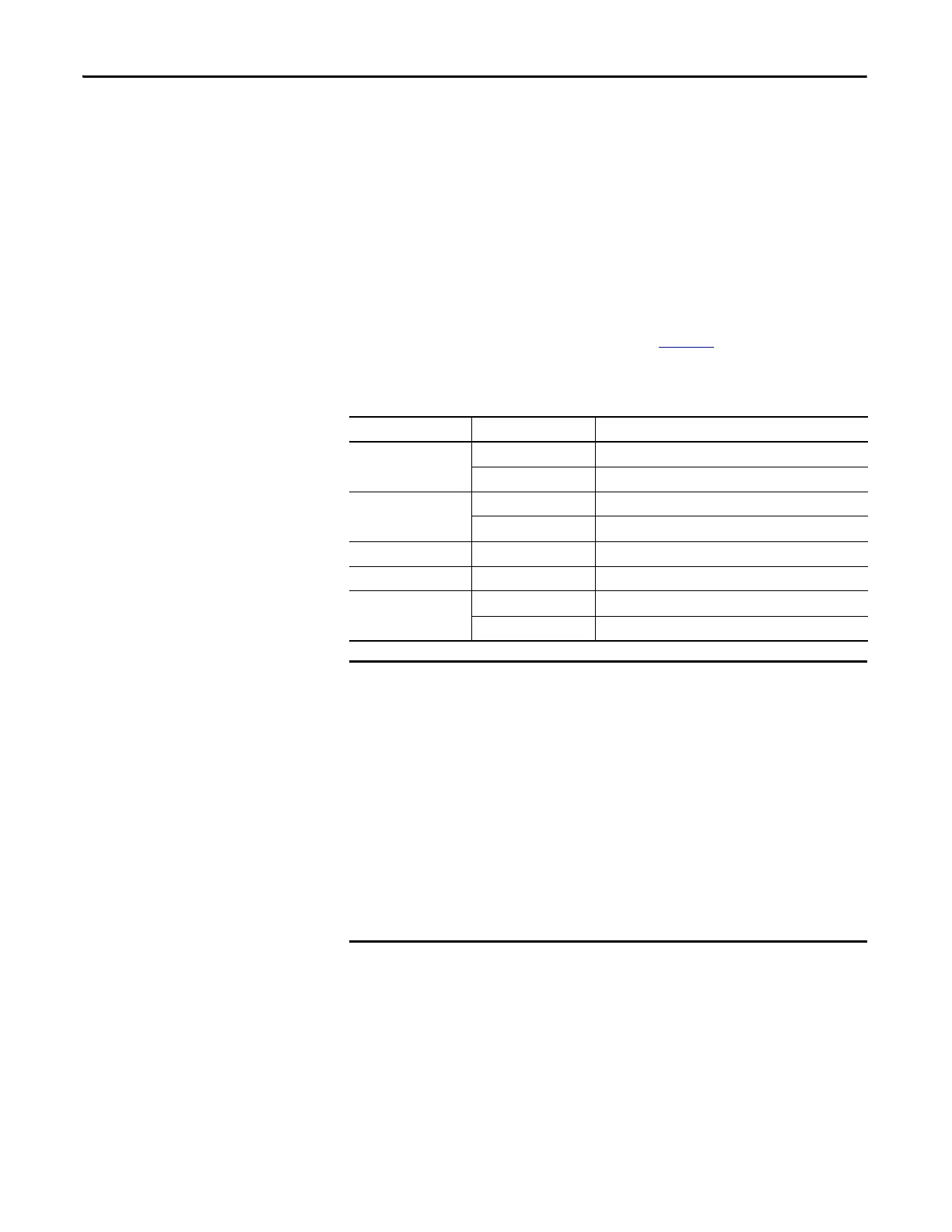

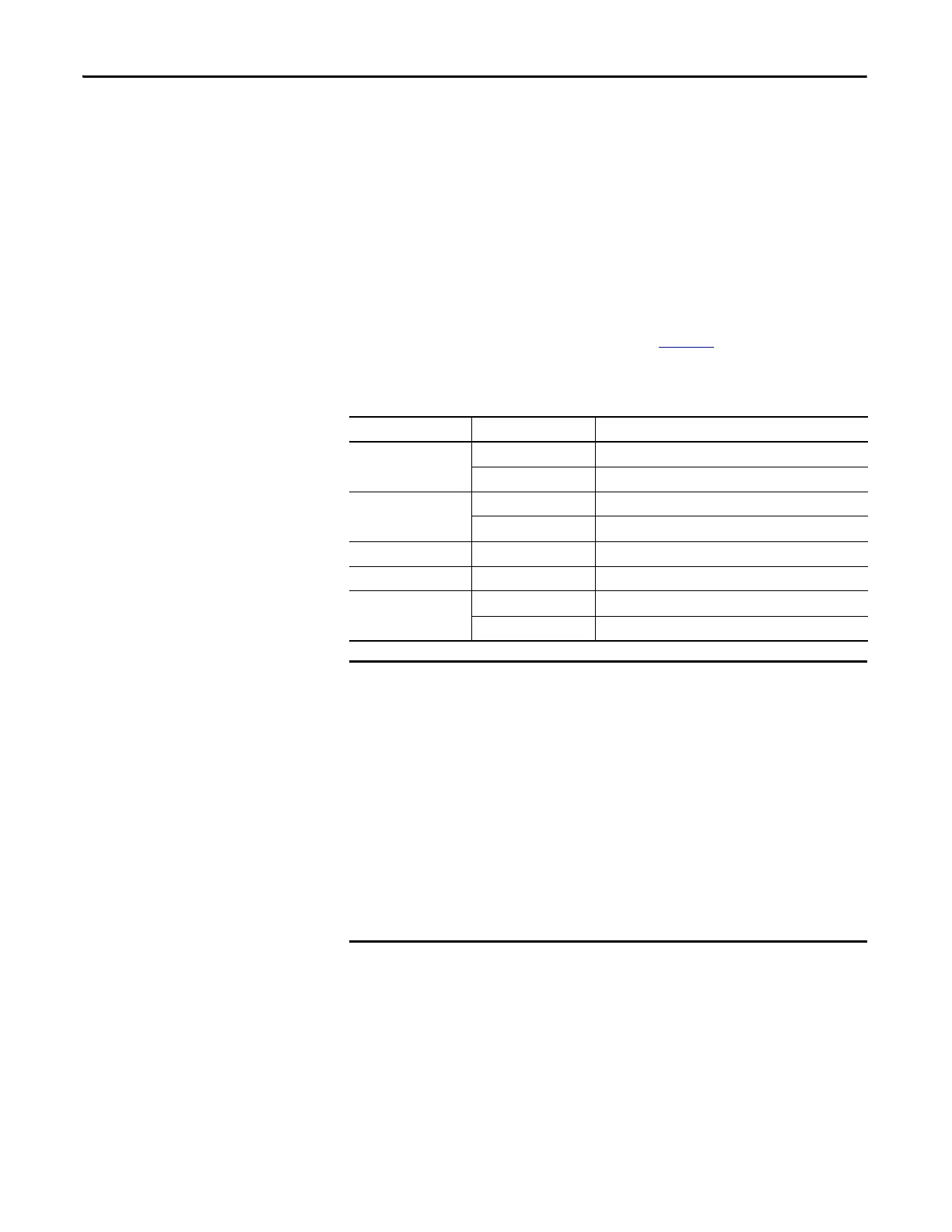

Table 23 - Calibration Instrumentation Specifications

Module Channel Input Type Recommended Instrument Specifications

1756-IF8I Current (mA) 1.00…20.00 mA source ±100 nA current

Voltage (V) 0…10V source ±2 µV voltage

1756-IRT8I RTD 1.0…487.0 Ω resistors ±0.01%

Thermocouple (mV) 0…100 mV source ±0.5 µV

1756-IR12 RTD 1.0…487.0 Ω resistors ±0.01%

1756-IT16 Thermocouple (mV) 0…100 mV source ±0.5 µV

1756-OF8I Current (mA) DMM with resolution better than 0.15 µA

Voltage (V) DMM with resolution better than 1.0 µV

Do not calibrate your module with an instrument that is less accurate than

those recommended. The following events can result:

• Calibration appears to occur normally but the module gives inaccurate

data during operation.

• A calibration fault occurs, forcing you to abort calibration.

• The I.Ch[x].CalibrationFault tag is set for the channel you attempted to

calibrate.

You can clear the tag by completing a valid calibration or cycling power

to the module. In this case, you must recalibrate the module with an

instrument as accurate as recommended.

Loading...

Loading...