88 Rockwell Automation Publication 1756-UM540E-EN-P - December 2017

Chapter 4 Temperature-sensing Analog Modules

Fault and Status Reporting

The module multicasts fault and status data with channel data to the owner and

listening controllers. The data is returned via module tags that you can monitor

in your Logix Designer application.

The following table lists the complete set of fault and status tags for

temperature-sensing modules. Check your module’s configuration in the Logix

Designer application to determine which tags are available. Refer to Analog I/O

Module Tag Definitions on page 181 for specific information on applying tags to

each module.

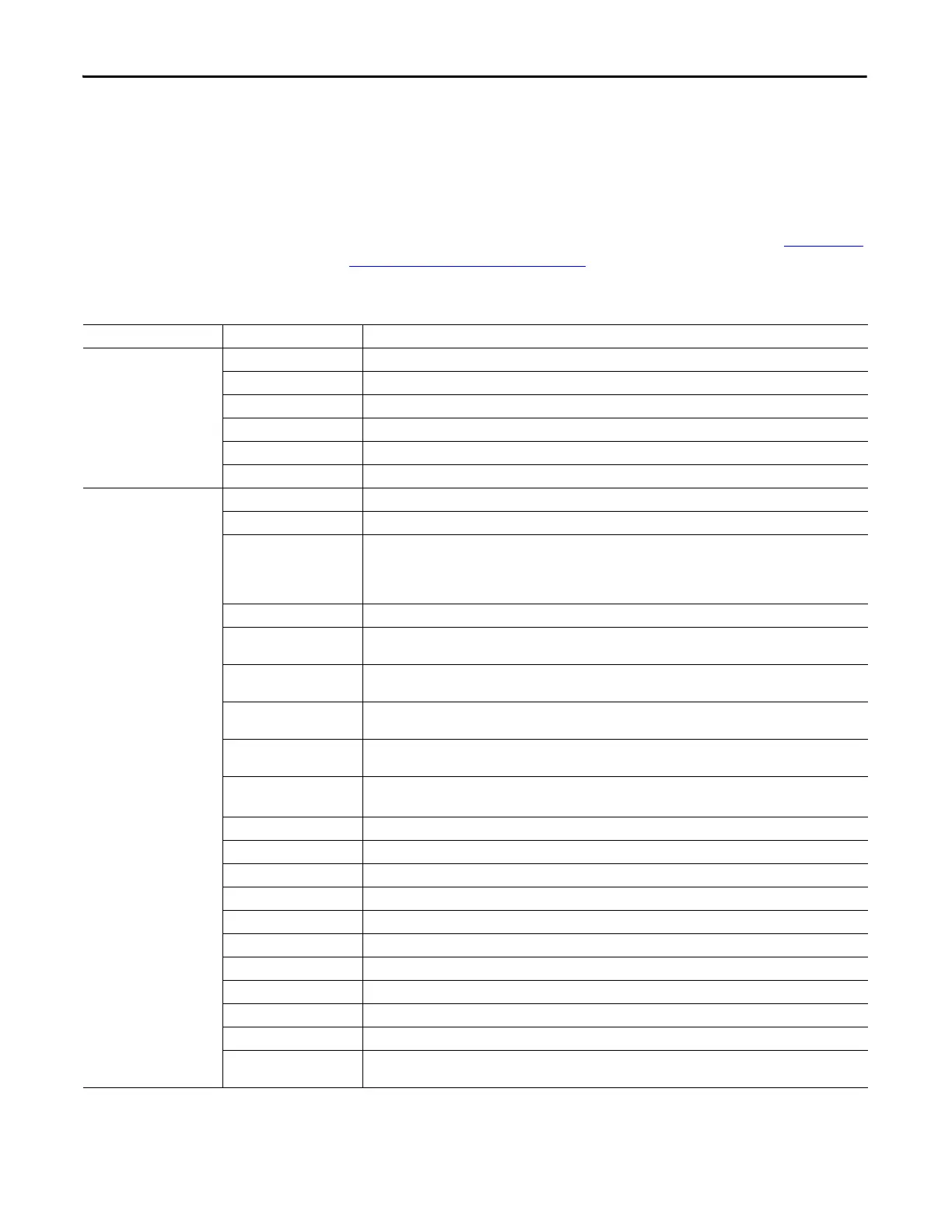

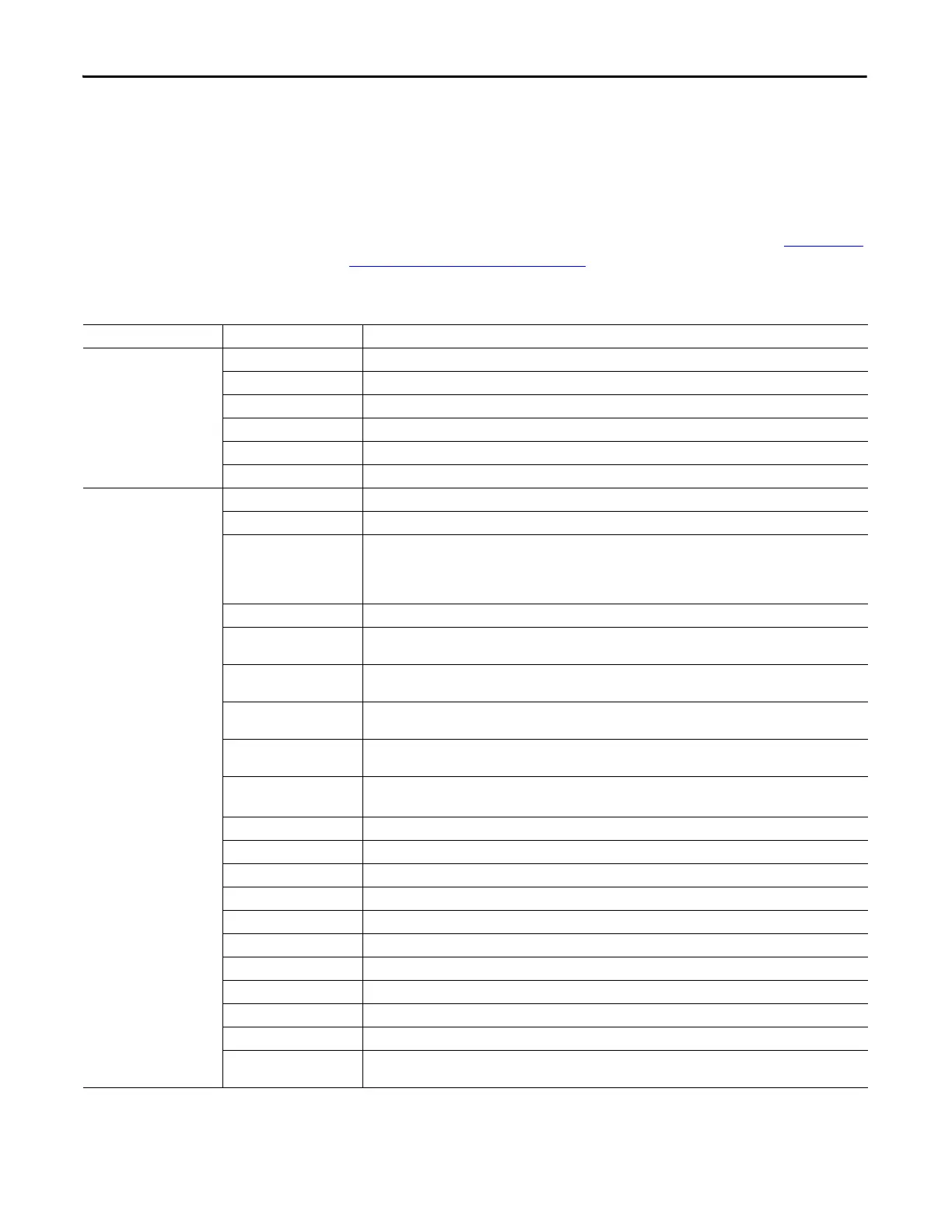

Table 19 - Fault and Status Data Tags

Data Type Tag Name Triggering Event That Sets Tag

Fault

Fault

(1)

The owner-controller loses its connection to the module.

CJ[x].Underrange The cold junction for the channel is below 0 °C.

CJ[x].Overrange The cold junction for the channel is above 86 °C.

Ch[x].Fault The channel data quality is bad.

Ch[x].Underrange The channel data is beneath the absolute minimum for this channel.

Ch[x].Overrange The channel data is above the absolute maximum for this channel.

Status

CIPSyncValid

(1)

Indicates whether the module is synchronized to a valid CIP Sync time master on the backplane.

CIPSyncTimeout

(1)

Indicates whether a valid time master on the backplane has timed out.

CIPSyncOffsetJump

(1)

Indicates a significant jump, that is, 1 ms or greater, in the CST and CIP Sync times sent from the Time Master to the

module. (The Time Master sends the CST and CIP Sync times to the module every second.)

When a significant jump occurs, this tag value becomes 1 but changes to 0 a second later unless another jump

occurred.

Ch[x].Uncertain The channel data can be imperfect.

Ch[x].LLAlarm The I.Ch[x].Data tag value is less than the C.Ch[x].LLAlarmLimit tag value, the O.Ch[x].LLAlarmEn tag is set and alarms

are enabled for the channel.

Ch[x].LAlarm The I.Ch[x].Data tag value is less than the C.Ch[x].LAlarmLimit tag value, the O.Ch[x].LAlarmEn tag is set and alarms

are enabled for the channel.

Ch[x].HAlarm The I.Ch[x].Data tag value is greater than the C.Ch[x].HAlarmLimit tag value, the O.Ch[x].HAlarmEn tag is set and

alarms are enabled for the channel.

Ch[x].HHAlarm The I.Ch[x].Data tag value is greater than the C.Ch[x].HHAlarmLimit tag value, the O.Ch[x].HHAlarmEn tag is set and

alarms are enabled for the channel.

Ch[x].RateAlarm The absolute change between consecutive channel samples exceeds the C.Ch[x].RateAlarmLimit tag value.

This alarm only applies to enabled Process alarms.

Ch[x].CalibrationFault The channel is not calibrated or the last attempted calibration for this channel failed.

Ch[x].Calibrating The channel is currently being calibrated.

Ch[x].CalGoodLowRef A valid Low Reference signal has been sampled on this channel.

Ch[x].CalBadLowRef An invalid Low Reference signal has been sampled on this channel.

Ch[x].CalGoodHighRef An valid High Reference signal has been sampled on this channel.

Ch[x].CalBadHighRef An invalid High Reference signal has been sampled on this channel.

Ch[x].CalSuccessful Calibration on this channel is complete and the Calibrating state has been exited.

Ch[x].RateOfChange The change in channel data since last sample in Engineering Units/Second.

Ch[x].Data The channel data in scaled Engineering Units.

Timestamp

(1)

A 64-bit timestamp indicating when all 8 channels were last sampled in terms of CIPSync time.

RollingTimestamp

(1)

16-bit timestamp that ‘rolls’ from 0…32,767 ms. Compatible with existing PID instruction to automatically calculate

sample deltas. The timestamp changes when any one of the output channels is updated.

(1) This tag provides module-wide data and affects all channels simultaneously.

Loading...

Loading...