ASDA Series Application Note Application Examples

March, 2015 3-39

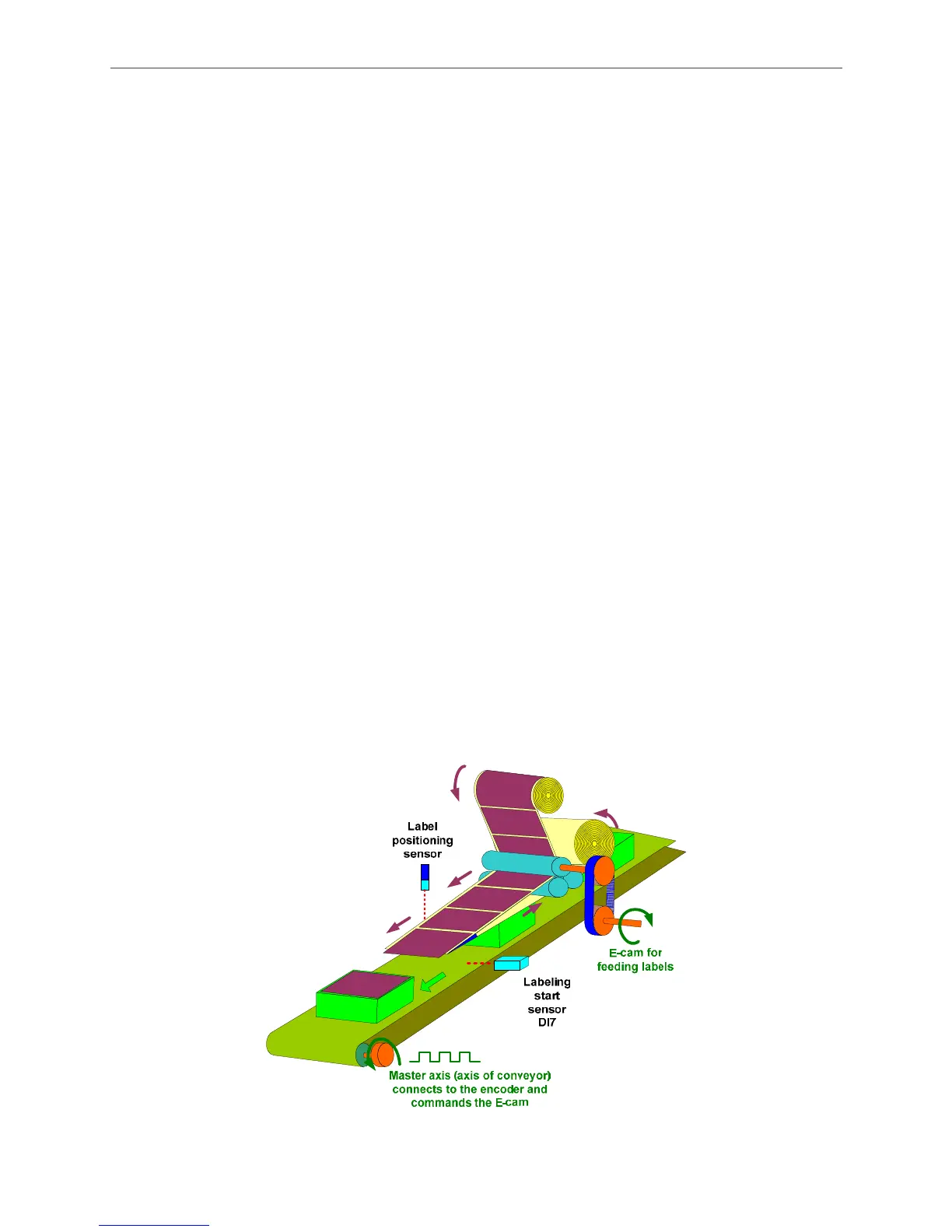

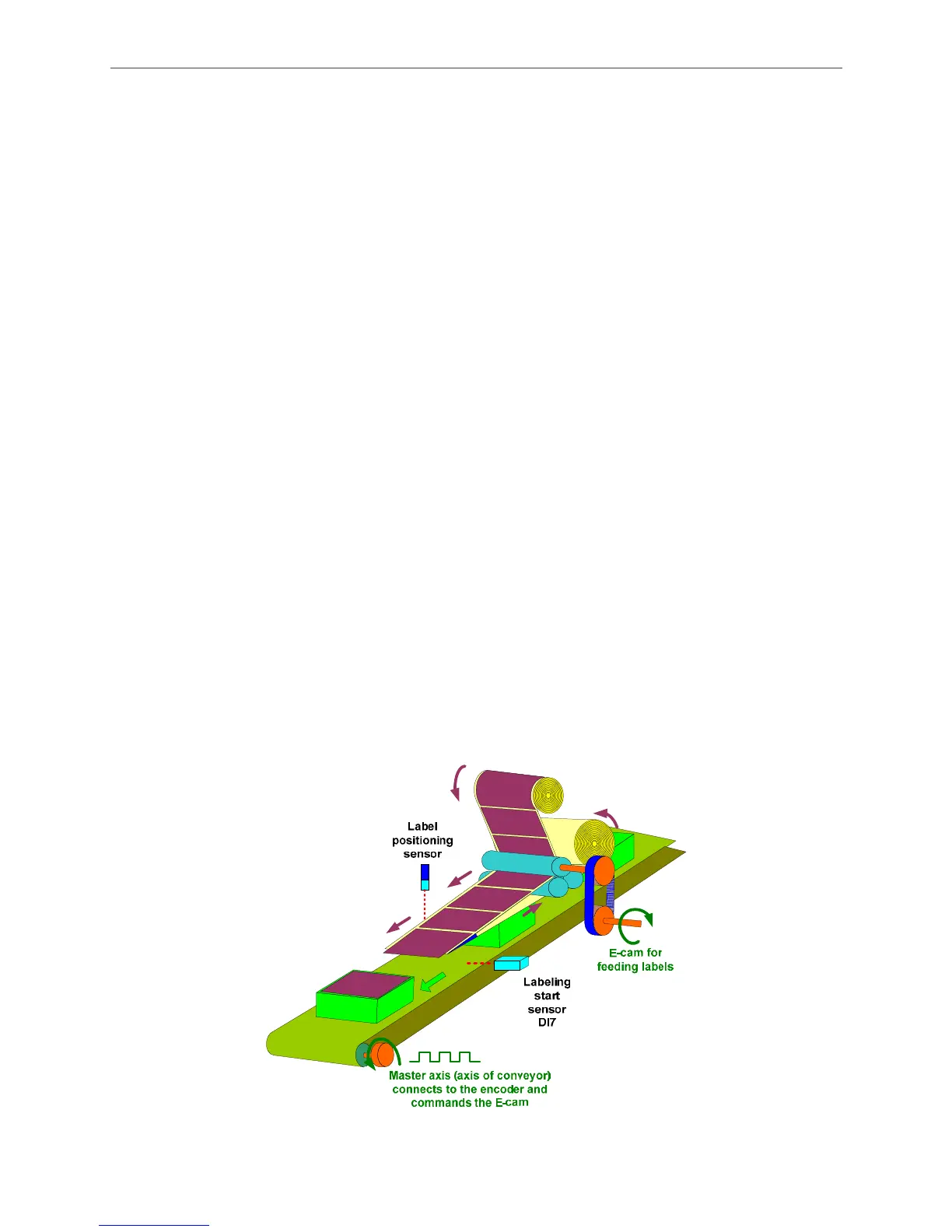

3.3 Application to Labeling Machine

3.3.1 Description

This chapter is aiming at the application of ASDA-A2 on labeling machine. Electronic cam is

applied to control the speed of delivering labels and enables the packages to be delivered in the

same speed so as to labeling. This application could be classified to flying shear. The length of

label should be adjustable, the position should be accurate when delivering labels and the

delivering speed should be the same as the main conveyor. For the convenience of operator,

only photoelectric switch is adjusted in this application, such as label location position and

labeling start position. (No controller and HMI is in the system since ASDA-A2 is good enough to

satisfy all demands.)

Besides the detailed description of labeling motion, this chapter will introduce how E-cam curve

is created in speed section by Delta’s ASDA soft. This curve has a very long constant speed

section, which is the table creation basis in rotary cutoff and similar applications.

Together with PR commands, E-cam can easily satisfy the controlling demand in ASDA-A2.

3.3.2 System Plan

The axis of conveyor is the master axis which is mainly for transporting objects. Camshaft axis is

in charge of controlling the pace of labeling according to the pulse speed sent by master axis,

see diagram 3.3.1. In this application, the label waiting position (controlled by label positioning

sensor) has to be very accurate. The position error should within 1mm only each time. As for the

design of E-cam curve and function, it must consider that the label length should be adjustable.

Thus, the setting of E-cam should be set to the longest length for operation.

Figure 3.3.1 Labeling machine system

Loading...

Loading...