Application Examples ASDA Series Application Note

3-40 March, 2015

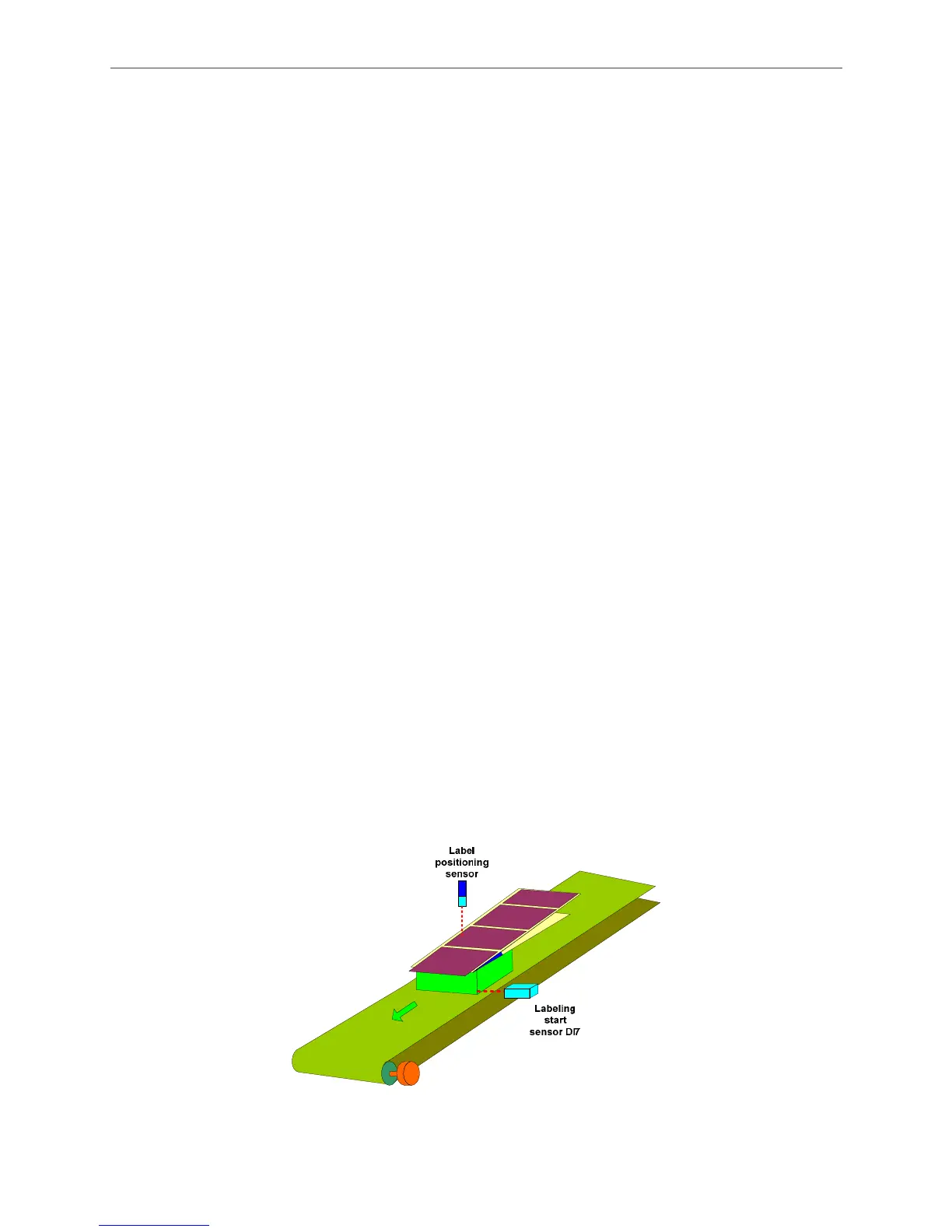

3.3.2.1 Master Axis – Axis of Conveyor

It transports the to-be labeled objects, such as packing box. The pulse signals are sent out to

command the camshaft axis simultaneously in order to control the labeling speed.

3.3.2.2 Camshaft Axis – Label Feeding Axis

Following the command of master axis, the camshaft axis executes labeling according to the

pace of master axis. When delivering the label, the pace should be accurate and stable. It should

be controlled to operate the same speed with the master axis while labeling, otherwise the label

will be pasted uneven.

3.3.2.3 Label Positioning Sensor

The label positioning sensor decides the outstretched length of label while the label is waiting to

be pasted. It can be operated by moving the photoelectric switch (label positioning sensor).

3.3.2.4 Labeling Start Sensor

When DI7 receives the signal from labeling start sensor, it will control E-cam to engage and the

camshaft axis will synchronize with the master axis. When E-cam starts to accelerate and reach

the same speed as master axis, the label will just be pasted on the to-be-labeled object. It will not

disengage until the labeling is completed.

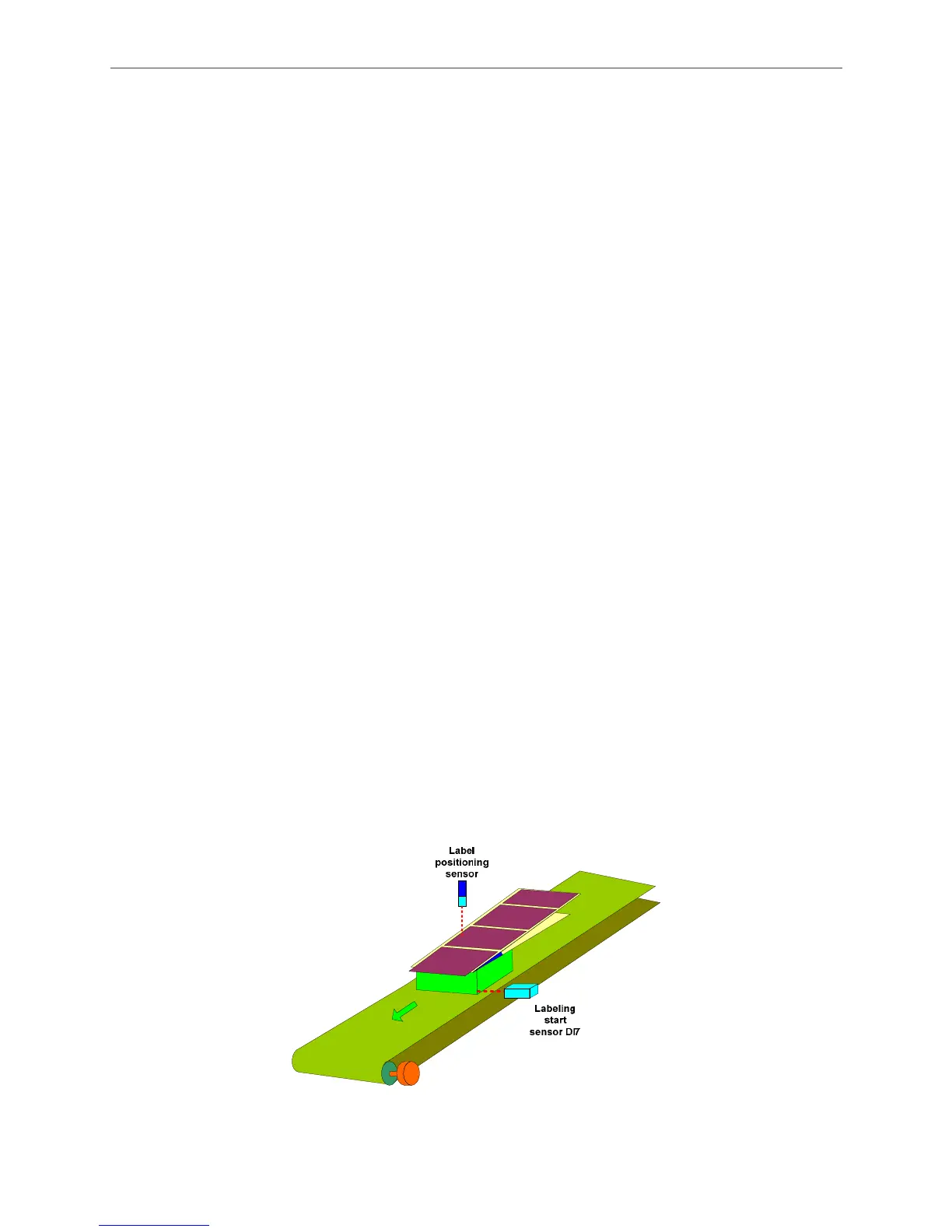

3.3.3 Setting of Servo System

3.3.3.1 Camshaft is Enabled and Starts to Label

When the object on the conveyor is detected by labeling start sensor, the camshaft is enabled.

The label axis follows the master axis until the labeling is completed. Then, the camshaft

disengages and its operation is controlled by label positioning sensor. See Figure 3.3.2 and

3.3.3.

Loading...

Loading...