Application Examples ASDA Series Application Note

3-104 March, 2015

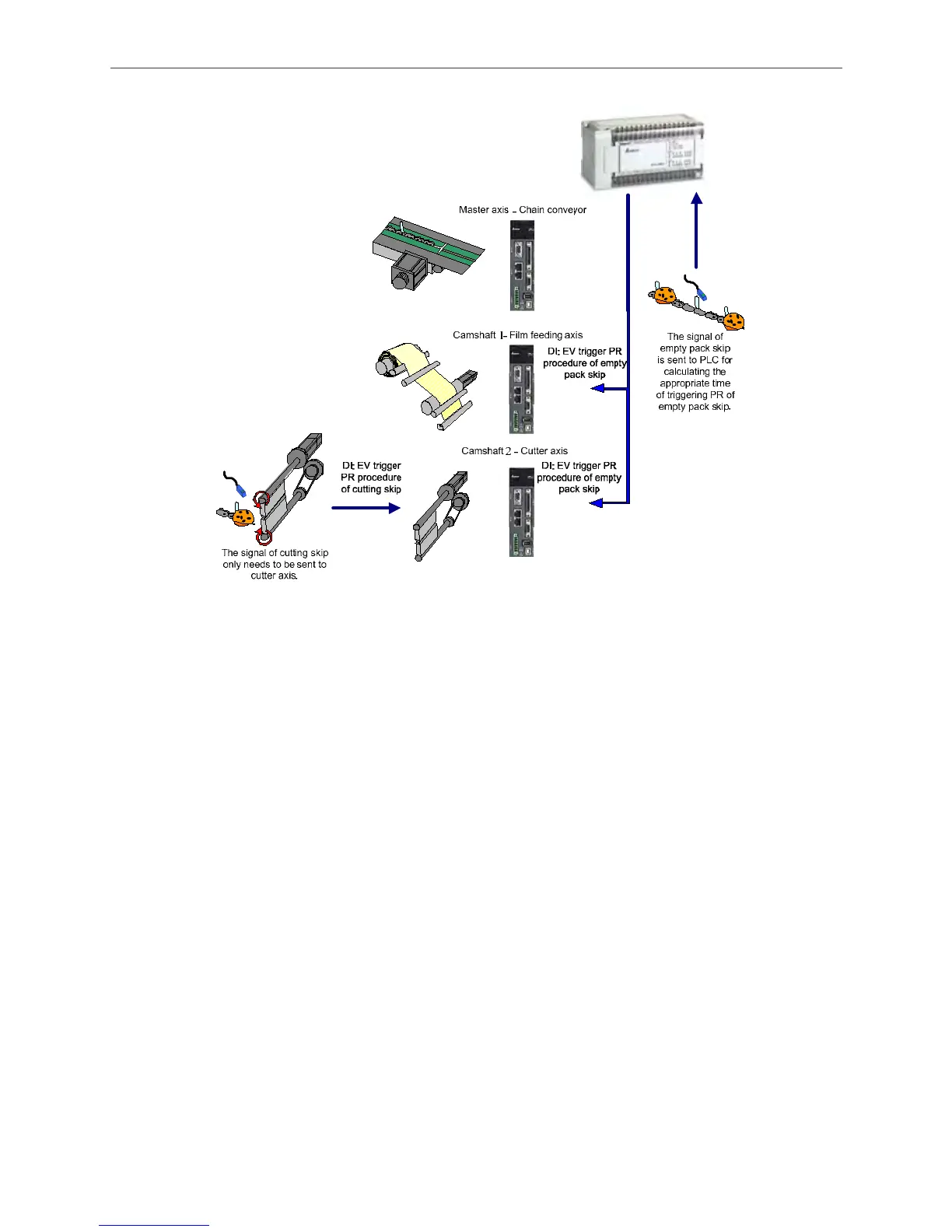

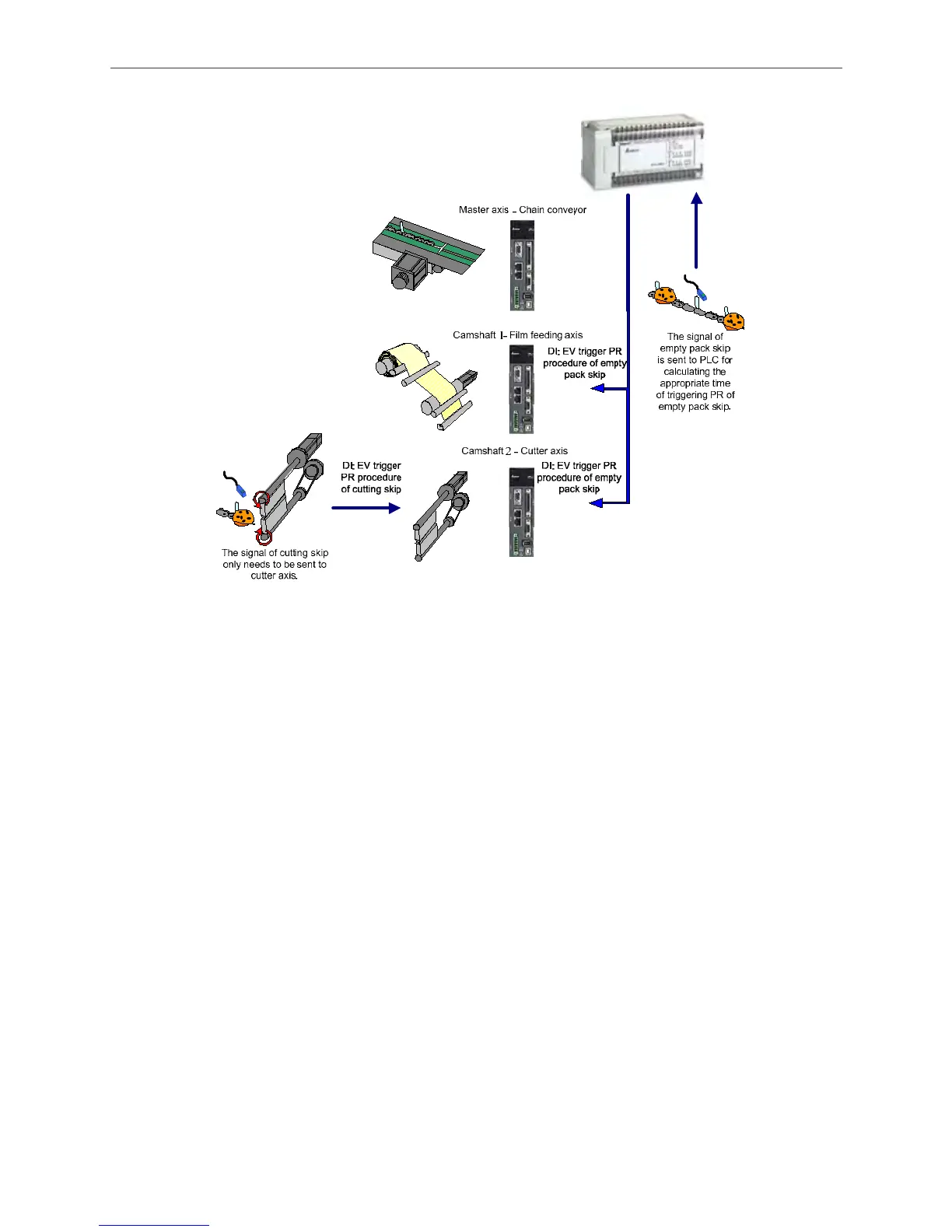

Figure 3.8.3 System Configuration – Signal of Empty Pack Skip and Cutting Skip

3.8.3.2 Features

Synchronous Capture Axis

Synchronous capture axis applying here is to ensure it can automatically adjust its motion and

overcome the problem of incorrect packaging and wrong cutting position when master axis

(material feeding axis) transmits the abnormal pulse to the slaves (film feeding axis and cutter

axis).

In flying shear application, camshaft operates in accordance with the operational distance set by

the receiving pulse of master axis. Therefore, if the master axis is unable to output the set pulse

length, slaves will be unable to cut or pack in correct position. See figure 3.8.4. Assume the salve

axis is set to perform the cutting operation after receiving every 10000 pulses from the master

axis. If the master axis moves the same distance and pulses transmitted are fixed to 10000, then

the camshaft will not go wrong on cutting. If the master axis moves the same distance, but the

slave axis receives 11000 pulses instead of 10000 pulses, the slave axis will still perform the

cutting operation when receiving the 10000

th

pulse and it will therefore have shorter cutting

length. If the master axis moves the same distances, but the slave axis receives 9000 pulses

instead of 10000 pulses, the slave axis will perform the cutting operation when receiving the

10000

th

pulse and it will therefore have longer cutting length.

Loading...

Loading...