ASDA Series Application Note Application Examples

March, 2015 3-91

curve. Set P5-88.U to C could avoid the situation and have the same function as P5-88.U=4,

periodically disengage. Firmware version after V1.027 Sub.6 supports P5-88.U=C). It also can

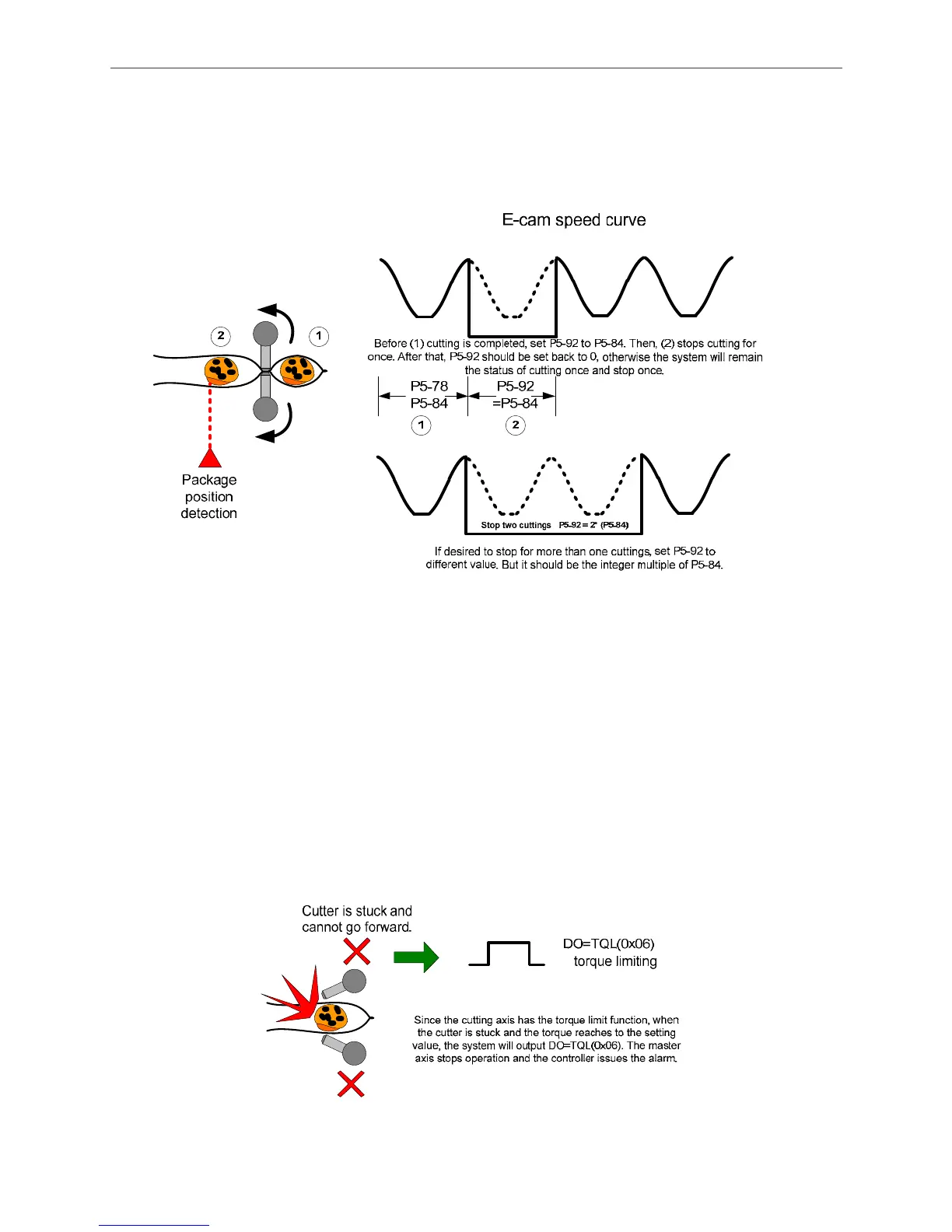

satisfy the demand of one or more cutting skips through adjusting lead pulse (P5-92). See Figure

3.6.11.

Figure 3.6.11 Controls cutting by periodical lead pulse

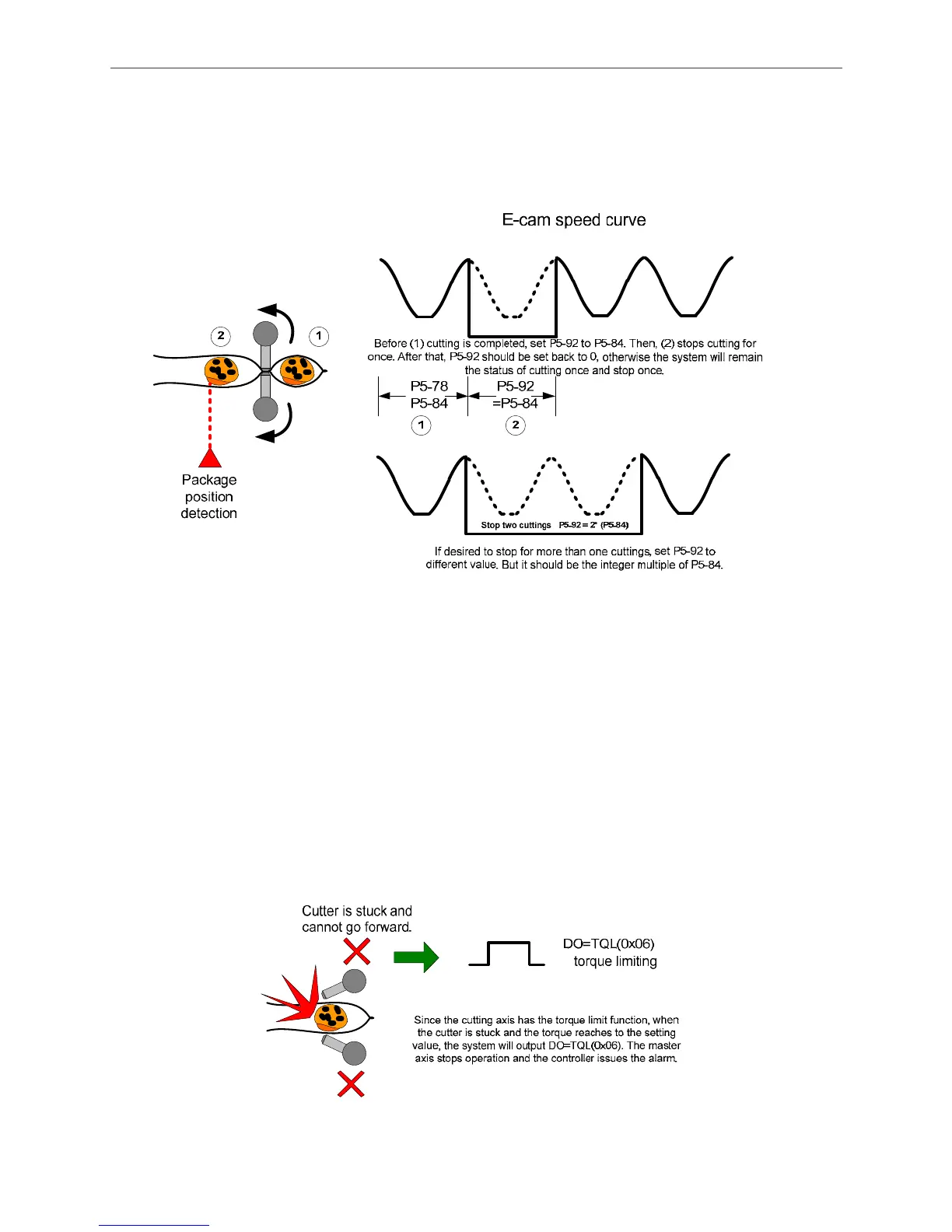

If the system cannot detect the wrong position of the package before entering the cutting area,

then users can apply torque limit function of the servo drive. It could limit the strength of cutter.

When the cutter reaches the setting value of torque limit, the DO signal will be issued to inform

the controller to stop delivering the film. And the alarm will be cleared by the operator. The

camshaft remains at engaging status at the moment and stops operation since the pulse stops

issuing. After removing the package, the master axis will keep delivering the film and the system

will continue the previous cycle. See Figure 3.6.12. Use torque limit as the mechanism protection

when the package is in wrong position, the system program should be taken into consideration. If

the system is in normal operation, and its toque value is close to the maximum value that servo

drive can output, then this way is inappropriate.

Figure 3.6.12 Use the torque limit to protect the mechanism

Loading...

Loading...