Chapter 4 Application Techniques ASDA Series Application Note

4-10 March, 2015

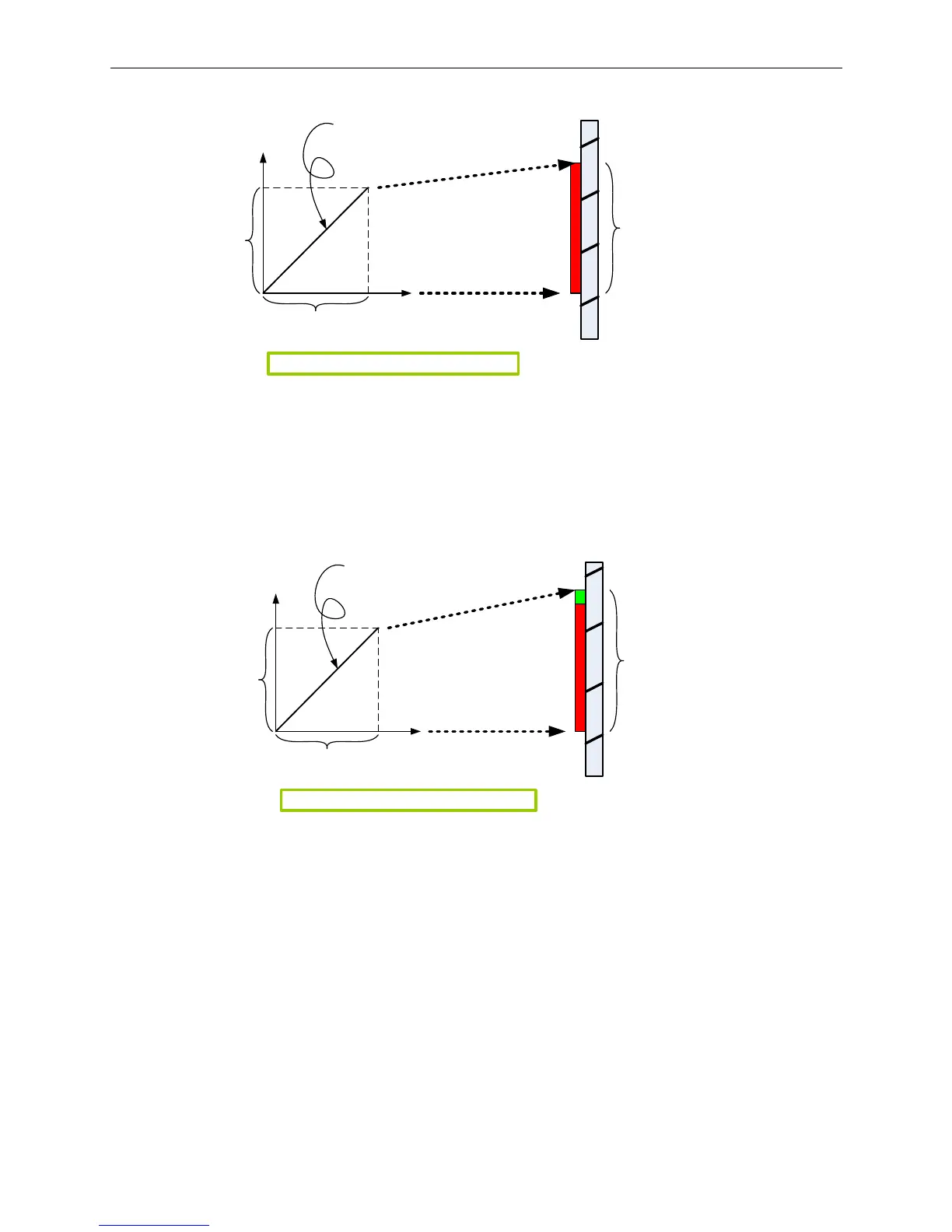

Command from host

controller (pulse)

Command

from the servo

PUU

200 pulse

200

PUU

Conversion capability of

E-Cam curve toward command

from host controller

Moving distance

of the mechanism

20 mm

1 pulse 1 PUU 0.1 mm

Figure 4.2.4 The Proper Correlation when No Tolerance Exists

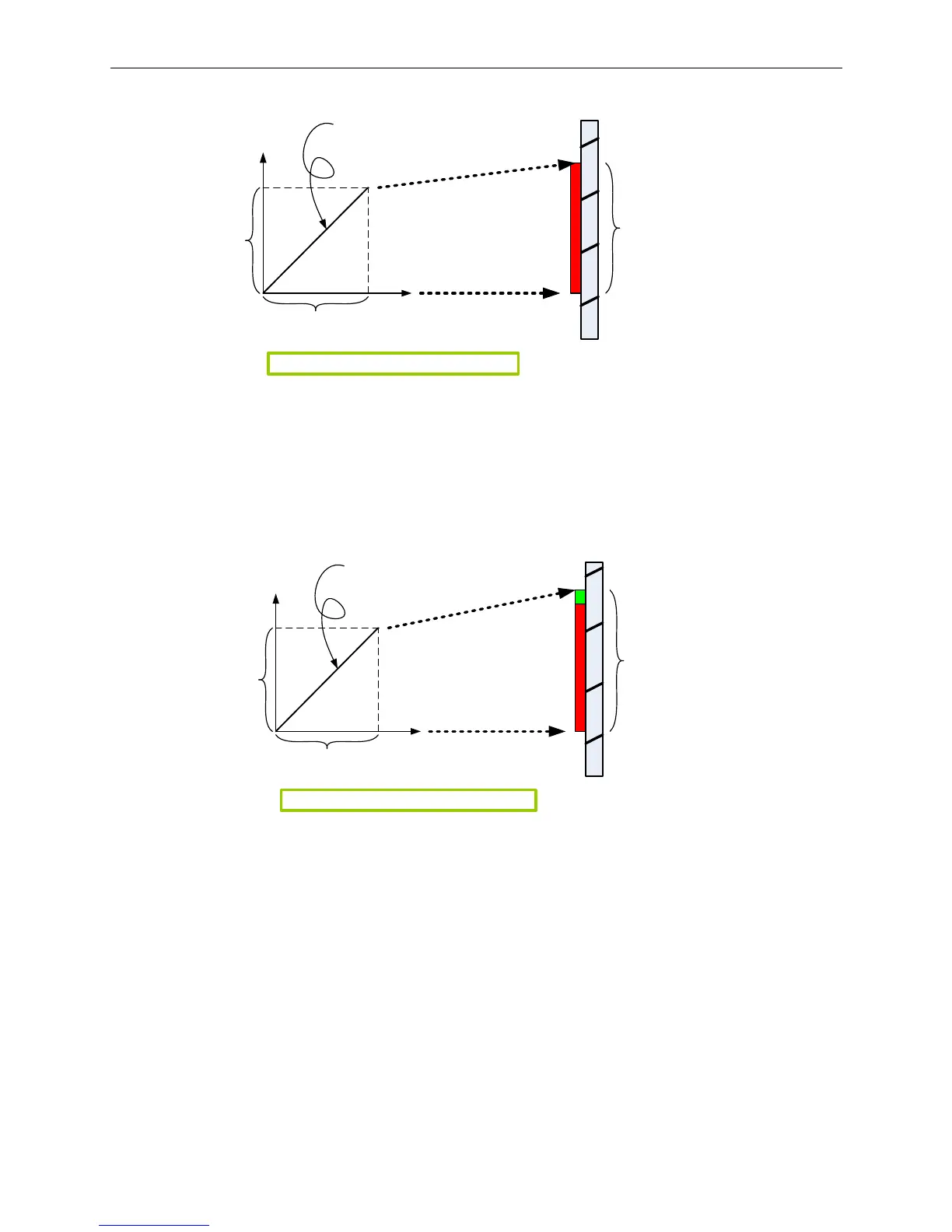

When there is a tolerance on the lead screw, the actual moving distance is 22 mm. The

correlation will be: 1 pulse 1 PUU 0.11 mm. Regarding this motion, the command resolution

was 0.1 mm/pulse and now becomes 0.11 mm/pulse. This is caused by the tolerance between

pitches.

Command from host

controller (pulse)

Command from

Servo Drive

PUU

200 pulse

200

PUU

Conversion capability of E-Cam

curve toward command from host

controller

Moving distance

of mechanism

22 mm

1 pulse 1 PUU 0.11 mm

Figure 4.2.5 The Inconsistent Correlation when Tolerance Exists

In this case, an E-Cam curve can be used to modify the command resolution. If the new

correlation of E-Cam curve is 1 pulse 0.9091 PUU 0.1 mm, the correlation between host

command and the actual moving distance will be 1 pulse 0.1 mm. By applying the E-Cam

function, the command resolution of the host controller can be identical without being affected by

the tolerance. There is one thing worth noticing, the feedback pulse number from motor will differ

from the command value. For example, when the command is 220 pulse, the feedback pulse

from motor is 200 PUU and the actual moving distance of mechanism is 22 mm.

Loading...

Loading...