Maintenance

TROUBLESHOOTING

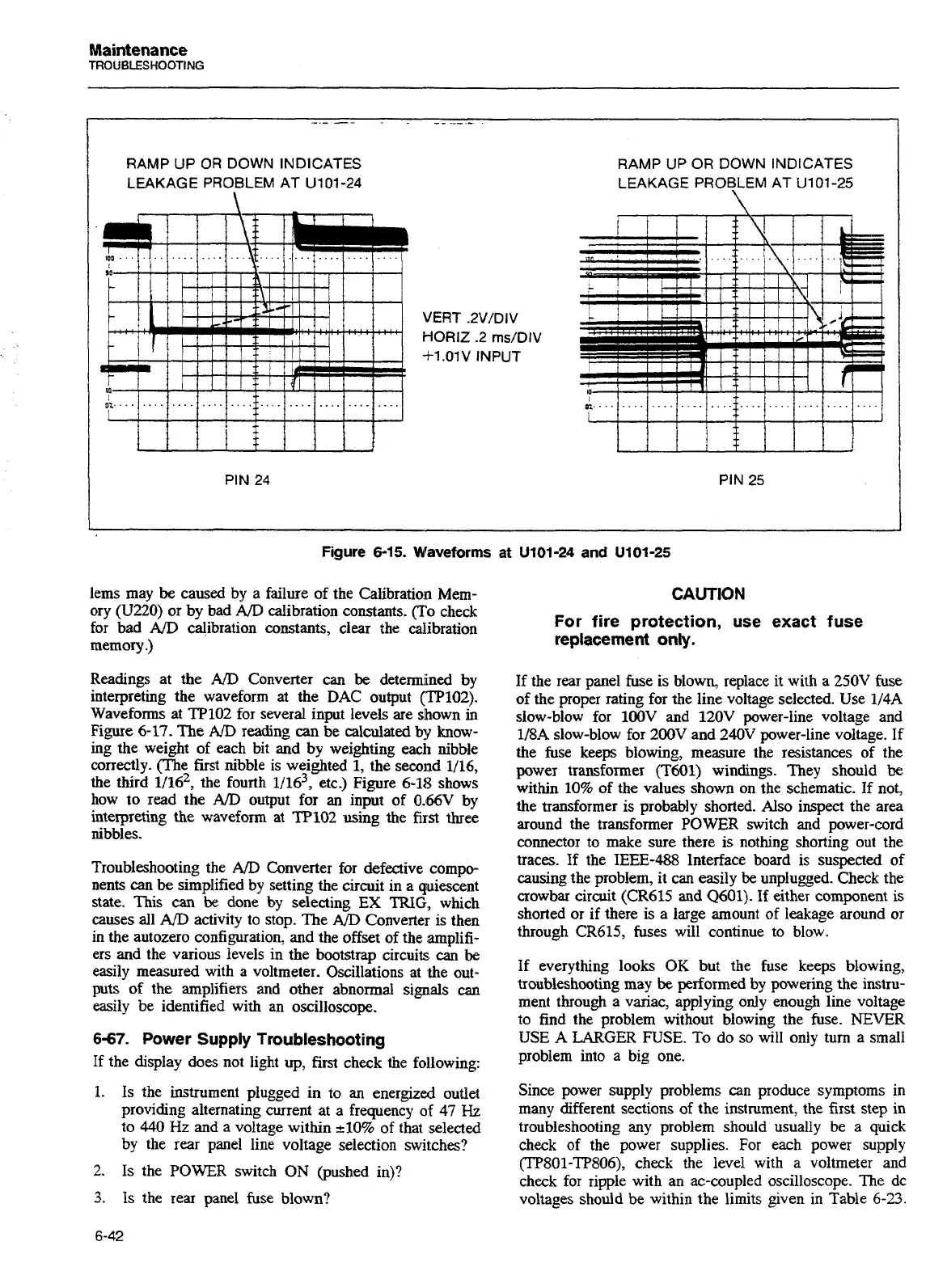

RAMP

UP

OR

DOWN INDICATES

LEAKAGE PROBLEM AT

U101-24

i,,.....

................

1

1

PIN

24

VERT .2V/DIV

HORIZ

.2

rns/DIV

+1.01V

INPUT

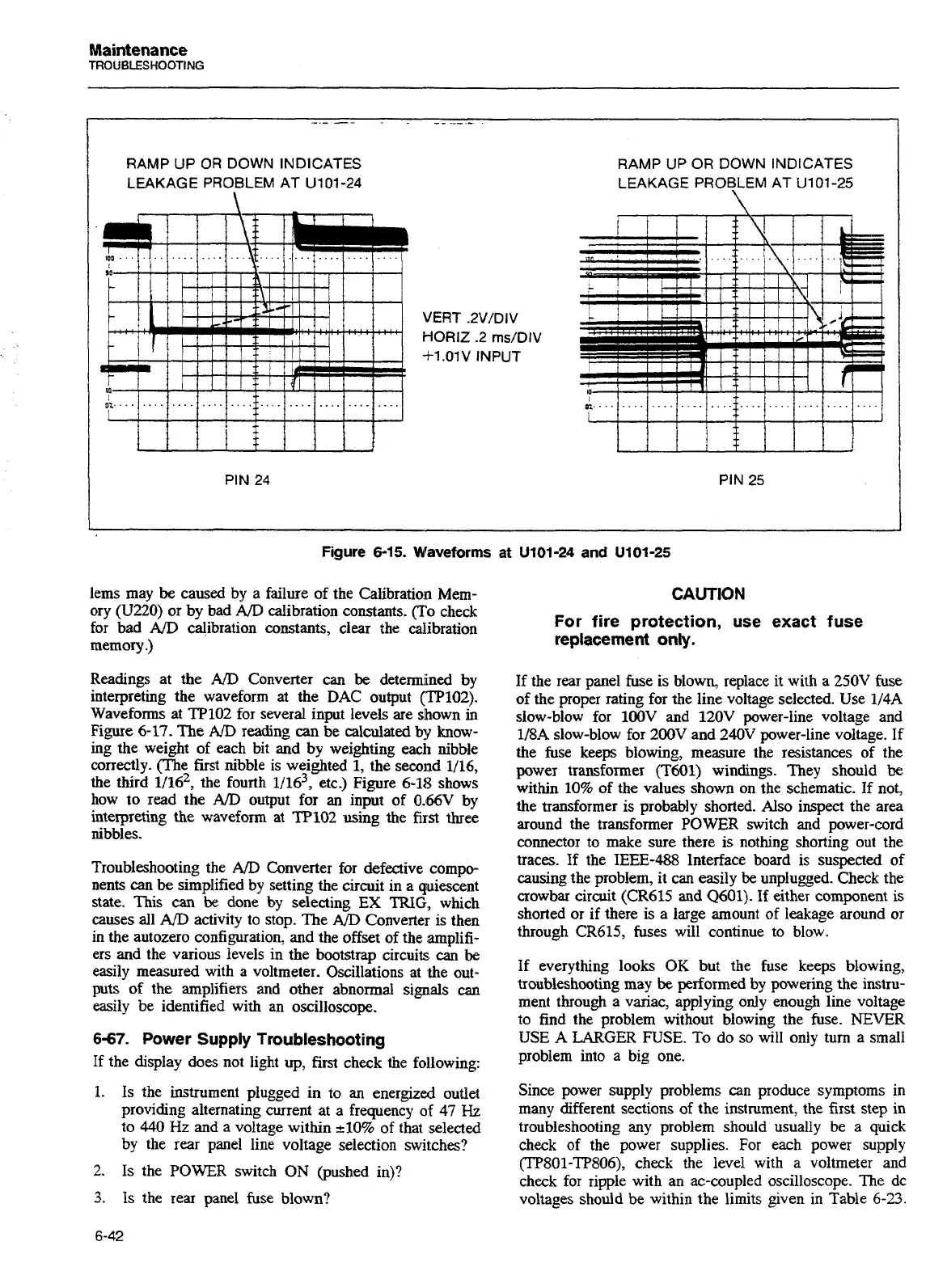

RAMP

UP

OR

DOWN

INDICATES

LEAKAGE

PROBLEM

AT

U101-25

\

PIN

25

Figure

6-15.

Waveforms

at

U101-24

and

U101-25

lems may

be

caused by a failure of the Ca1ibratio:n Mem-

ory (U220) or by bad

A/D

calibration constants. (To check

for bad

AID

calibration constants, clear the calibration

memory

.)

Readings at the

AD

Converter can

be

determined by

interpreting the waveform at the DAC output (T'P102).

Waveforms at TP102 for several input levels are slhown

in

Figure 6-17. The

AJD

reading

can

be calculated by know-

ing the weight of each bit and by weighting each nibble

correctly. (The first nibble is weighted

1,

the second 1/16,

the third 1116~~ the fourth l/16~, etc.) Figure 6-18 shows

how to read the

A/D

output for

an

input of O.&V by

interpreting the waveform at TP102 using the first three

nibbles.

Troubleshooting the

A/D

Converter for defective compo-

nents

can

be

simplified by setting the circuit in a quiescent

state. This

can

be done by selecting

EX

TRIG, which

causes all

AID

activity to stop. The

AD

Converter is then

in the autozero configuration, and the offset of the arnplifi-

ers and the various levels in the bootstrap circuits

can

be

easily measured with a voltmeter. Oscillations at ,the out-

puts of the amplifiers and other abnormal signals

can

easily be identified with an oscilloscope.

6-67.

Power Supply Troubleshooting

If the display does not light up, first check the foilowing:

1.

Is the instrument plugged in to

an

energized outlet

providing alternating current at a frequency

of

47

Hz

to 440

Hz

and a voltage within 210% of that selected

by the rear panel line voltage selection switches?

2.

Is the

POWER

switch

ON

(pushed in)?

3.

Is the rear panel fuse blown?

CAUTION

For fire protection, use exact fuse

replacement only.

If the rear panel fuse is blown, replace it with a 250V fuse

of the proper rating for the line voltage selected. Use

114A

slow-blow for lOOV and 120V power-line voltage and

1/8A slow-blow for

200V

and 240V power-line voltage. If

the fuse keeps blowing, measure the resistances of the

power transformer (T601) windings. They should

be

within 10% of the values shown on the schematic. If not,

the transformer is probably shorted. Also inspect the area

around the transformer POWER switch and power-cord

connector to make sure there is nothing shorting out the

traces. If the IEEE-488 Interface board is suspected of

causing the problem, it can easily

be

unplugged. Check: the

crowbar circuit (CR615 and Q601). If either component is

shorted or if there is a large amount of leakage around or

through

CR615, fuses will continue to blow.

If everything looks

OK but the fuse keeps blowing,

troubleshooting may

be

performed by powering the instru-

ment through a variac, applying only enough line voltage

to find the problem without blowing the fuse.

NEVER

USE

A

LARGER FUSE. To do so will only turn a simall

problem into a big one.

Since power supply problems can produce symptoms in

many different sections of the inst~ment, the first step in

troubleshooting any problem should usually be

a

quick

check of the power supplies. For each power supply

(TP801-TP806), check the level with a voltmeter and

check for ripple with an ac-coupled oscilloscope.

The

dc

voltages should be within the limits given in Table

6-23.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...