Maintenance

TROUBLESHOOTING

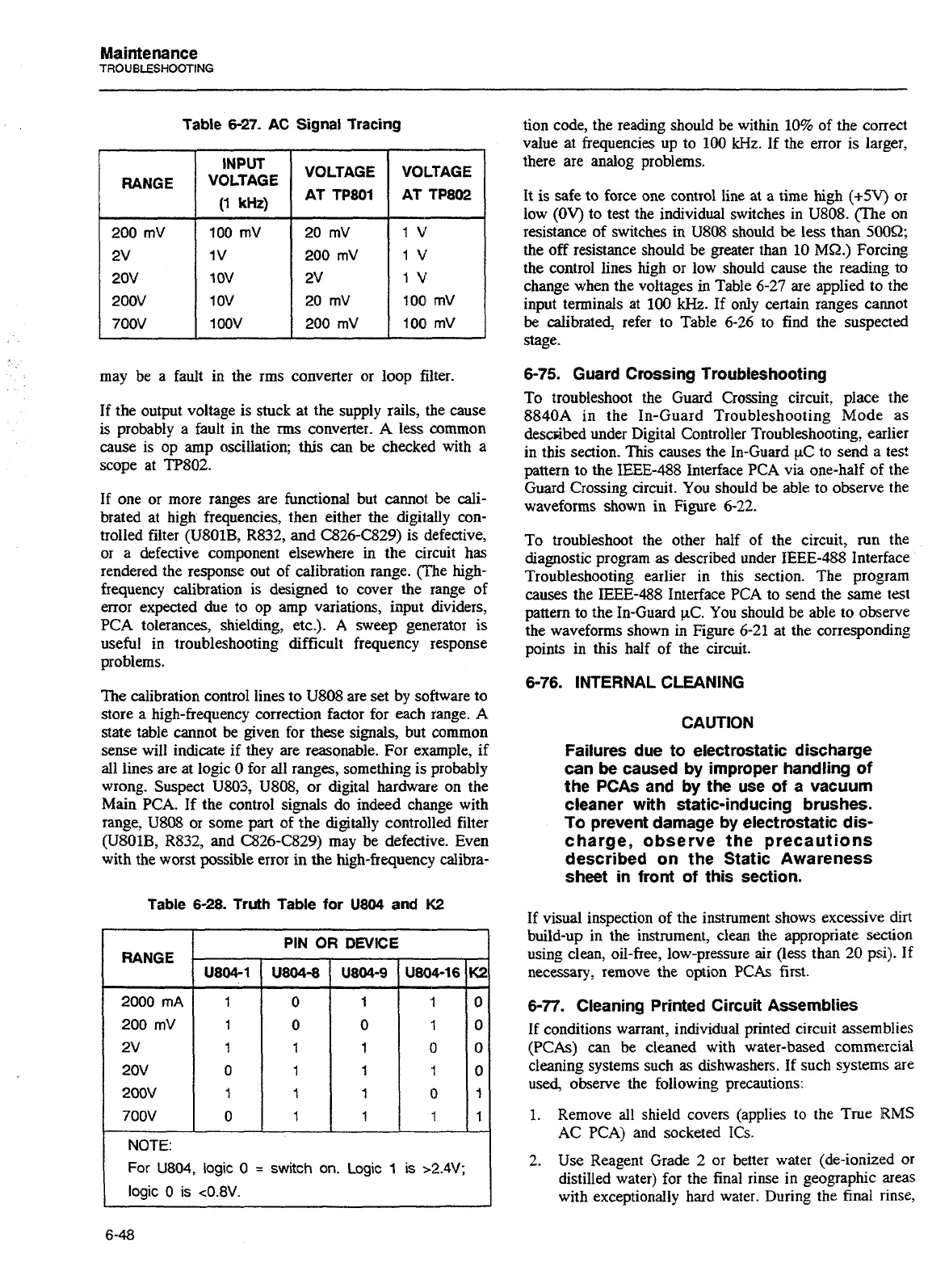

Table

6-27.

AC

Signal Tracing

RANGE

may be a fault in the rms converter or loop filter.

200 mV

2v

20v

200v

700V

If the output voltage is stuck at the supply rails, the cause

is probably a fault in the

rms

converter.

A

less common

cause is op amp oscillation; this can be checked with a

scope at TP802.

INPUT

VOLTAGE

(1

kHz)

If one or more ranges are functional but cannot

be

cali-

brated at high frequencies, then either the digitally con-

trolled filter (U801B7 R832, and C826-C829) is defective,

or a defective component elsewhere in the circuit has

rendered the response out of calibration range. (The high-

frequency calibration is designed to cover the range of

error expected due to op amp variations, iilput dividers,

PCA tolerances, shielding, etc.). A sweep generator is

useful in troubleshooting difficult frequency response

problems.

100 mV

1

v

1

OV

1

ov

1 OOV

The calibration control lines to U808 are set by software to

store a high-frequency correction factor for each range. A

state table cannot be given for these signals, but common

sense will indicate if they are reasonable. For example, if

all lines are at logic 0 for all ranges, something is probably

wrong. Suspect

U803, U808, or digital hardware on the

Main PCA. If the control signals do indeed change with

range,

U808 or some part of the digitally controlled filter

(U801B, R832, and C826-C829) may be defective. Even

with the worst possible error in

the

high-frequency calibra-

VOLTAGE

AT TP801

200 rnv

2v

20

rnv 100 rnv

200 rnV 100 rnV

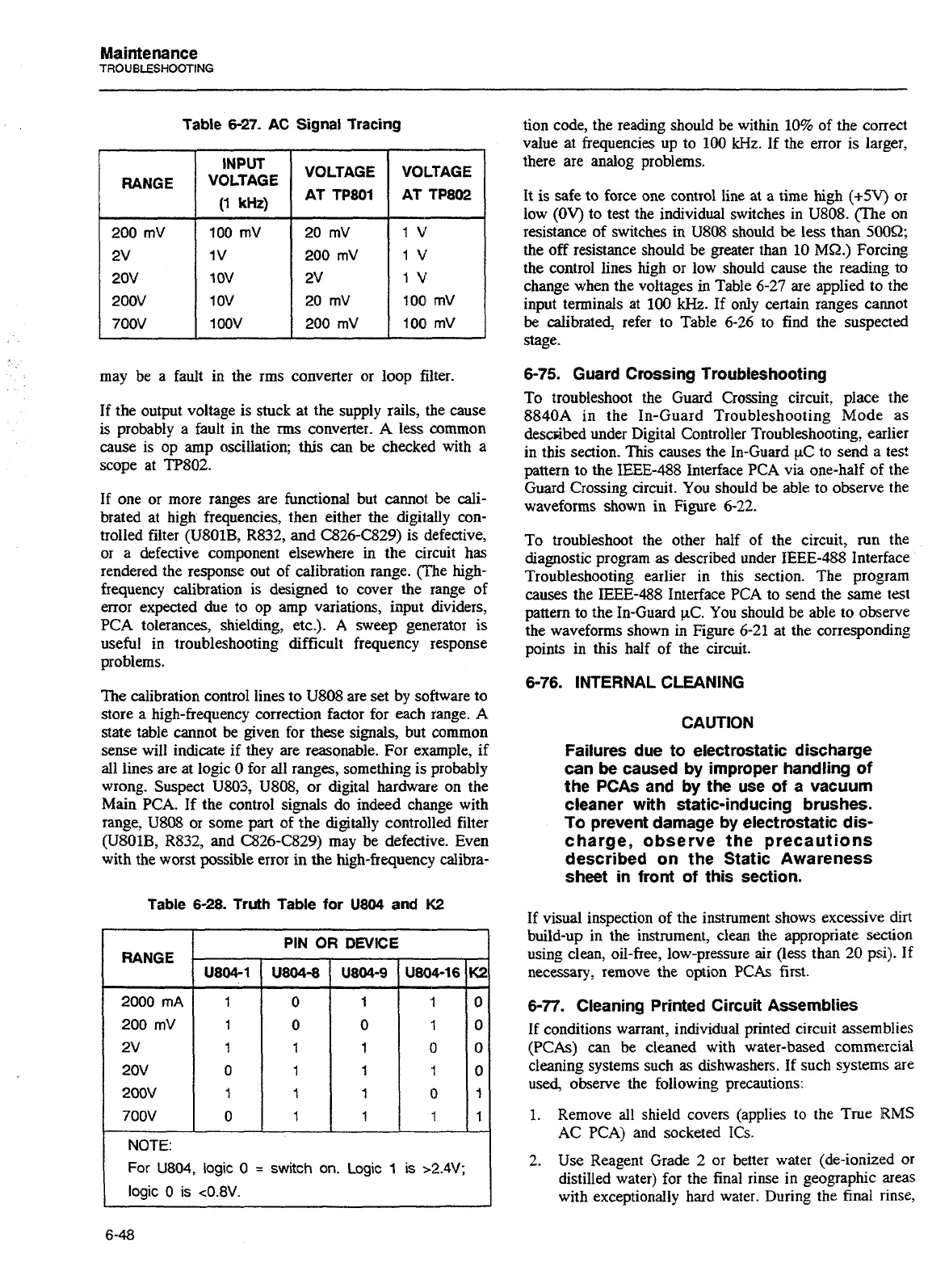

Table

6-28.

Truth

Table

for

US04

and

K2

VOLTAGE

AT TP802

tion code, the reading should be within 10% of the correct

value at frequencies up to

100

kHz. If the error is larger,

there are analog problems.

RANGE

2000

mA

200 mV

2v

20v

200v

700V

It is safe to force one control line

at

a time high

(+SV)

or

low

(OV)

to test the individual switches in U808. (The on

resistance of switches in U808 should

be

less than

50052;

the off resistance should be greater than 10

MQ.)

Forcing

the control lines high or low should cause the reading to

change when the voltages in Table 6-27 are applied to the

input terminals at 100

kHz.

If only certain ranges cannot

be

calibrated, refer to Table 6-26 to find the suspected

stage.

6-75.

Guard Crossing Troubleshooting

To troubleshoot the Guard Crossing circuit, place the

8840A in the In-Guard Troubleshooting Mode as

described under Digital Controller Troubleshooting, earlier

in this section. This causes the In-Guard

pC

to send

a

test

pattern to the IEEE-488 Interface PCA via one-half sf the

Guard Crossing circuit. You should

be

able to observe the

waveforms shown in Figure 6-22.

NOTE:

For

U804,

logic

0

=

switch

on. Logic

1

is

>2.4V;

logic

0

is

c0.8V.

PIN

OR

DEVICE

To troubleshoot the other half of the circuit,

run

the

diagnostic program

as

described under IEEE-488 Interface

Troubleshooting earlier in this section. The program

causes the

IEEE-488

Interface PCA to send the same test

pattern to the In-Guard

PC.

You should be able to observe

the waveforms shown in Figure 6-21 at the corresponding

points in this half of the circuit.

U804-1

1

1

1

0

1

0

6-76.

INTERNAL CLEANING

CAUTION

U804-8

0

0

1

1

1

1

Failures due to electrostatic discharge

can

be

caused

by

improper handling

of

the PCAs

and

by

the

use of a vacuum

cleaner with static-inducing brushes.

To

prevent damage

by

electrostatic dis-

charge, observe the precautions

described on the Static Awareness

sheet in front of this section.

If visual inspection of the instrument shows excessive dirt

build-up in the instrument, clean the appropriate section

using clean, oil-free, low-pressure air (less than 20 psi). If

necessary, remove the option PCAs first.

U804-9

1

0

1

1

1

1

6-77.

Cleaning Printed Circuit Assemblies

If conditions warrant, individual printed circuit assem.blies

(PCAs)

can

be cleaned with water-based commercial

cleaning systems such

as

dishwashers. If such systems are

used, observe the following precautions:

U804-16

'1

'I

0

,t

0

I

1.

Remove all shield covers (applies to the True

RMS

AC PCA) and socketed ICs.

K2

0

0

0

0

I

1

2. Use Reagent Grade

2

or better water (de-ionized or

distilled water) for the final rinse in geographic areas

with exceptionally hard water. During the final rinse,

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...