Maintenance

INTERNAL

CLEANING

spray or run the water so that the surface is thoroughly

covered to remove all ionized material.

3.

Thoroughly

dry

all PCAs using one of the following

methods:

a. Preferably, the PCA should be dried

in

a low-

temperature drying chamber or infrared drying

rack with

a

temperature range of

49°C

to

72°C

(120°F

to

160°F').

b.

If

neither a clrying chamber nor

a

drying rack is

available, air

dry

the PCA at ambient room tem-

perature for at least two days.

A

satisfactory cleaning method consists of holding the

PCAs

under hot running water until they

are

clean. Follow

this wash with

a

final rinse.

(See

consideration

2,

above.)

6-78.

Cleaning After Soldering

CAUTION

T.M.C.

Cleaner and similar products; can

can

attack

the

nylon

latches and other

plastic pieces.

If

a

PCA has

been

soldered, it should first

be

cleaned with

SPRAYON

T.M.C Cleaner" (rosin

flux

remover) or

equivalent.

The

PCA should then be cleaned with water

as

described above.

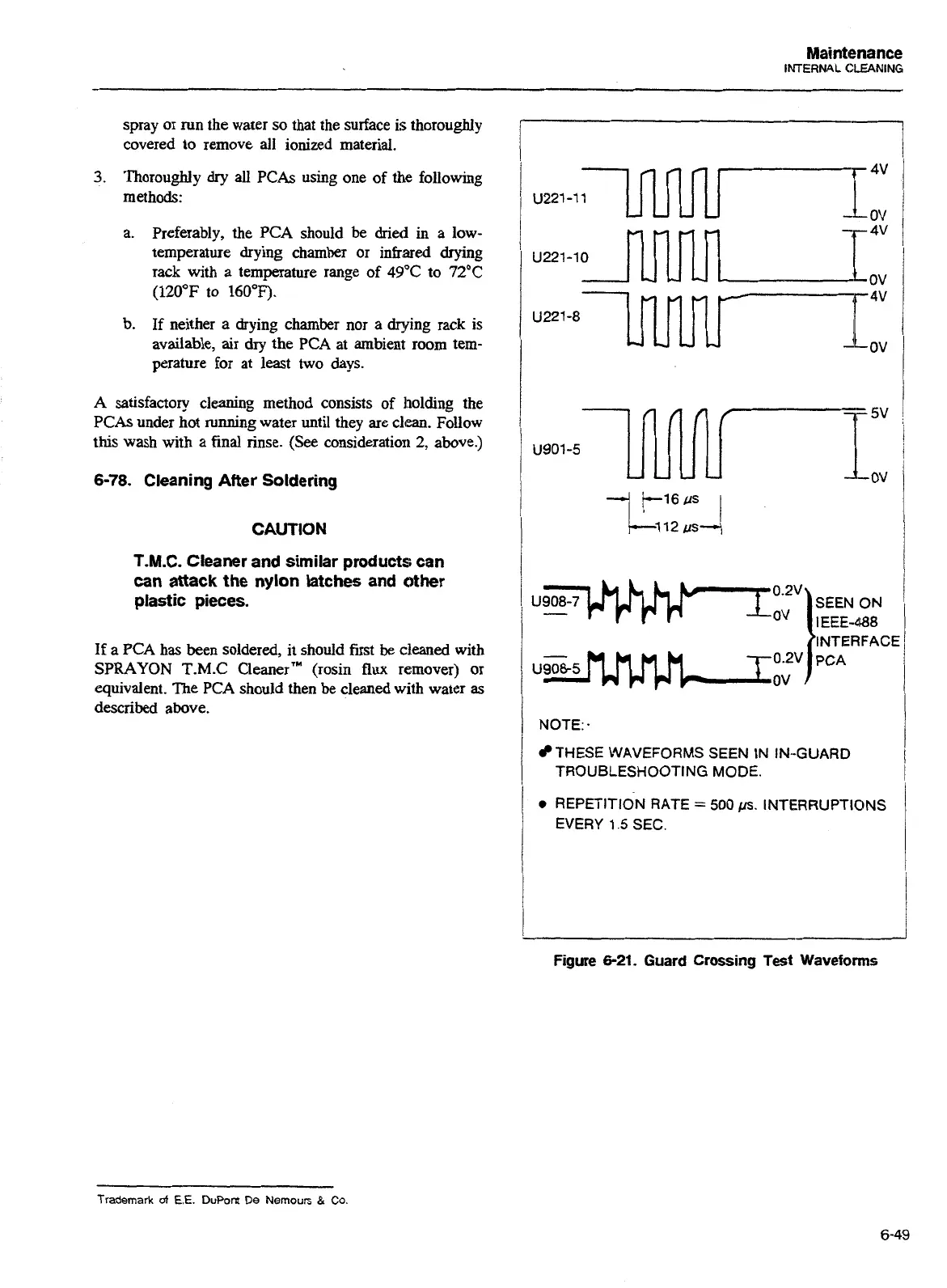

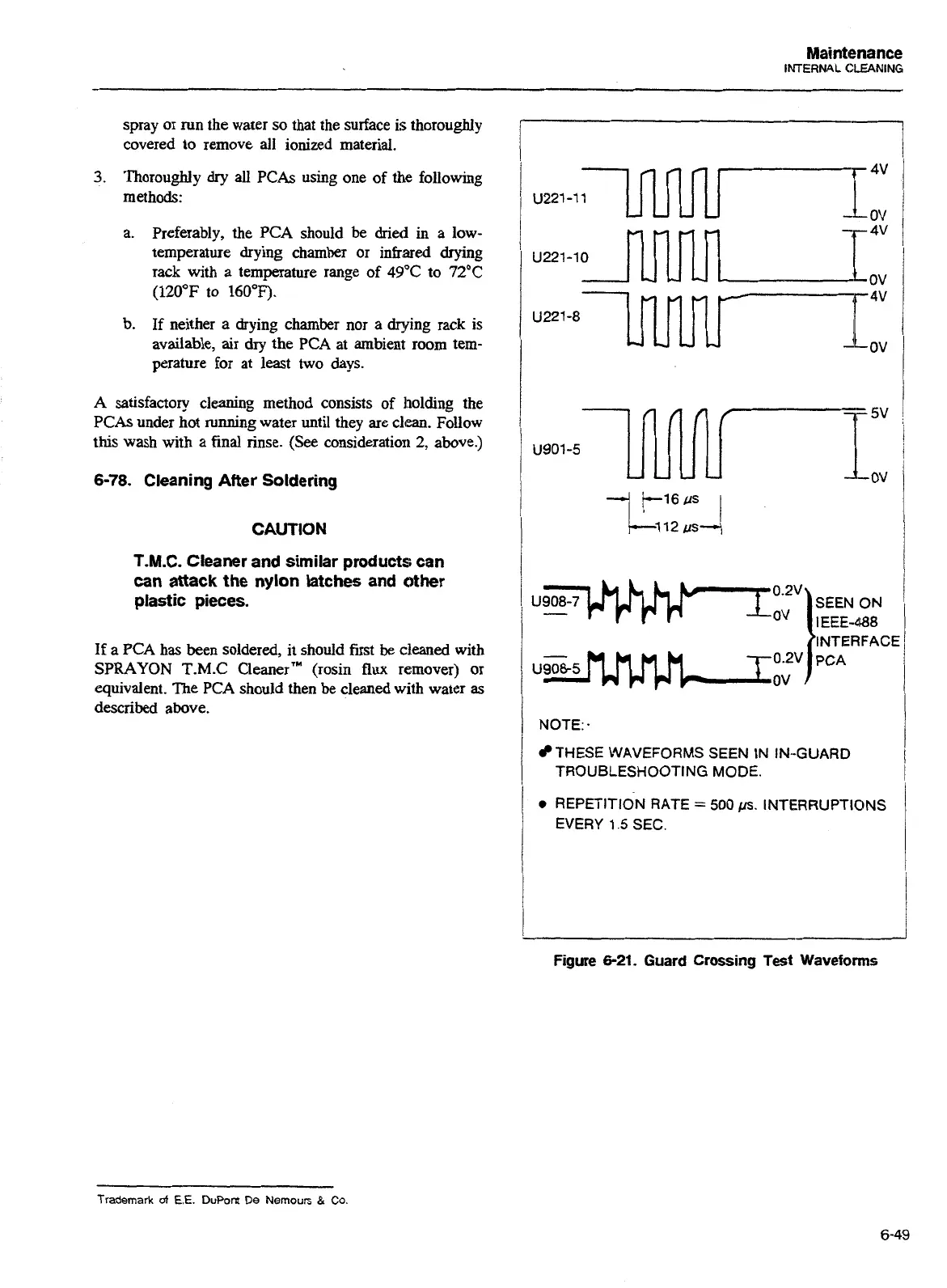

SEEN ON

I

EEE-4188

NOTE:.

THESE WAVEFORMS SEEN IN IN-GUARD

TROUBLESHOOTING MODE.

REPETITION

RATE

=

500

G.

INTERRUPTIONS

EVERY

1.5

SEC.

Figure

6-21.

Guard Crossing

Test

Waveforms

Trademark

of

E.E.

DuPont

De

Nemourj

&

Co.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...