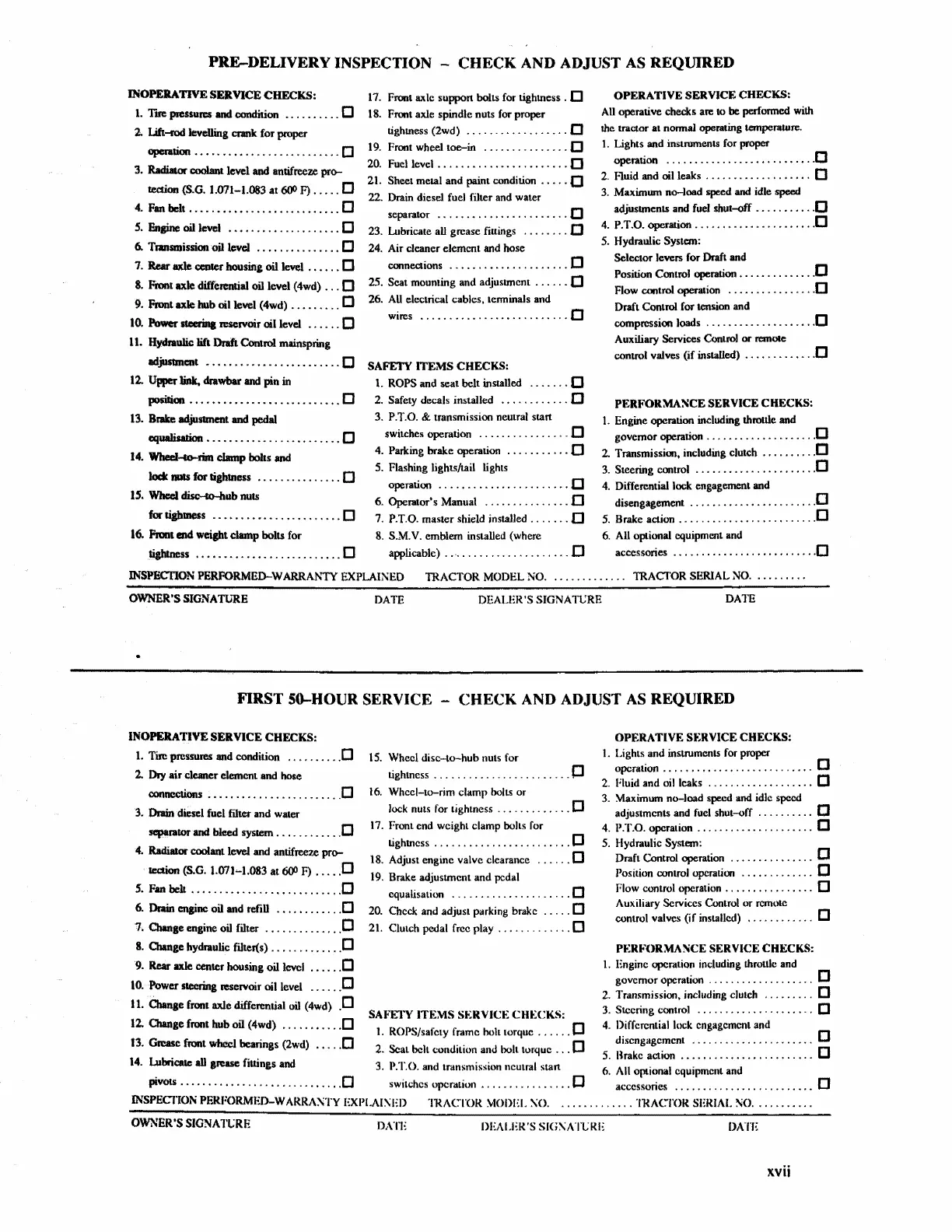

PRE-DELIVERY INSPECTION

CHECK

AND ADJUST

AS

REQUIRED

INOPERATIVE

SERVICE

CHECKS:

1.

Tire

pressures and condition

•.........

0

2.

Uft-rod

levelling crank for proper

operation

..•..•.••••............•..

0

3.

Radiator

coolant level

and

antifreeze

pro-

tection (S.G. 1.071-1.083

at

6()0 F)

.....

0

4.

Fan

belt

.....•••••.................

0

s.

Engine

oil

teve1

....................

D

6. Tnmsmission oil level

...............

0

7.

Rear

axle

CC11ler

housing oil level

..••..

0

8.

Front

ax.le differential oil level (

4wd)

...

0

9.

Front

ax.le

hub

oil level (4wd)

..•......

0

10.

Power

steering

reservoir oil level

......

CJ

11.

Hydraulic

lift

Draft Control mainspring

adjusbnc:nt

•••.•.•••...............

CJ

12.

Upper

link.

drawbar and pin in

position

•••••••••••...•.........••.

0

ll.

Brake adjustment and

pedal

equalilation

•....••.................

CJ

14.

Whee.1.-IO-rim

clamp bolts and

lock

nuas

for

liptness

...............

0

15.

Wheel

disc-to-hub nuts

for

tigbmess

.......................

0

16.

Front end weight clamp bolts for

tightness

..........................

CJ

17. Front axle support bolts for

tightness.

0

18.

Front axle spindle nuts for

proper

tightness

(2wd)

..................

0

19.

Front wheel

toe-in

...............

0

20.

Fuel level

.......................

0

21. Sheet metal

and

paint condition

.....

0

22. Drain diesel fuel filter and water

separator

.......................

0

23. Lubricate all grease fiuings

........

0

24.

Air cleaner

element

and

hose

connections . . .

.•.............

a

25. Scat mounting and adjustment

......

0

26. All electrical cables, tenninals and

wires

...............•..........

0

SAFETY

ITEMS

CHECKS:

1.

ROPS

and

seat

belt installed

.......

0

2. Safety decals installed

............

0

3.

P.T.O.

& transmission neutral start

switches open1tion

................

0

4. Parking brake aperation

...........

0

5. Flashing lights/tail lights

operation

.......................

0

6. Operator's Manual

...............

0

7.

P.T.O.

master

shield installed

.......

0

8.

S.M.V. emblem installed (where

applicable)

......................

D

OPERATIVE

SERVICE

CHECKS:

All operative checks

are

to

be performed

with

the tractor

at

normal operating temperature.

1.

Lights and instruments for

proper

operation

...........................

a

2.

Fluid and oil leaks

...................

a

3. Maximum

no-load

speed

and

idle speed

adjustments

and fuel

shut-off

...........

C

4.

P.T.o. operar.ion

...•..•.•.............

a

5.

Hydraulic System:

Selector levers for Draft and

Position Control operation

..............

C

Flow cootrol operation

................

D

Draft Control for tension and

compression loads

....................

C

Auxiliary Services Control or

remote

control valves

(if

installed)

.............

a

PERFORMASCE

SERVICE

CHECKS:

l.

Engine operation including throttle and

governor operation

....................

C

2.

Transmission, including clutch

..........

C

3. Steering control

......................

D

4.

Differential

Jock

engagement

and

disengagement

...........•.••........

0

5.

Brake action

.........................

D

6.

All optional equipment and

accessories

..........................

D

INSPECTION

PERFORMED-WARRANTY

EXPLAINED

lRACTOR

MODEL NO. . . . . . . . . . . . . . TRACT'OR SERIAL

NO

.........

.

OWNER'S

SIGNATURE

DATE

DEALER'S SIGNATURE

DATE

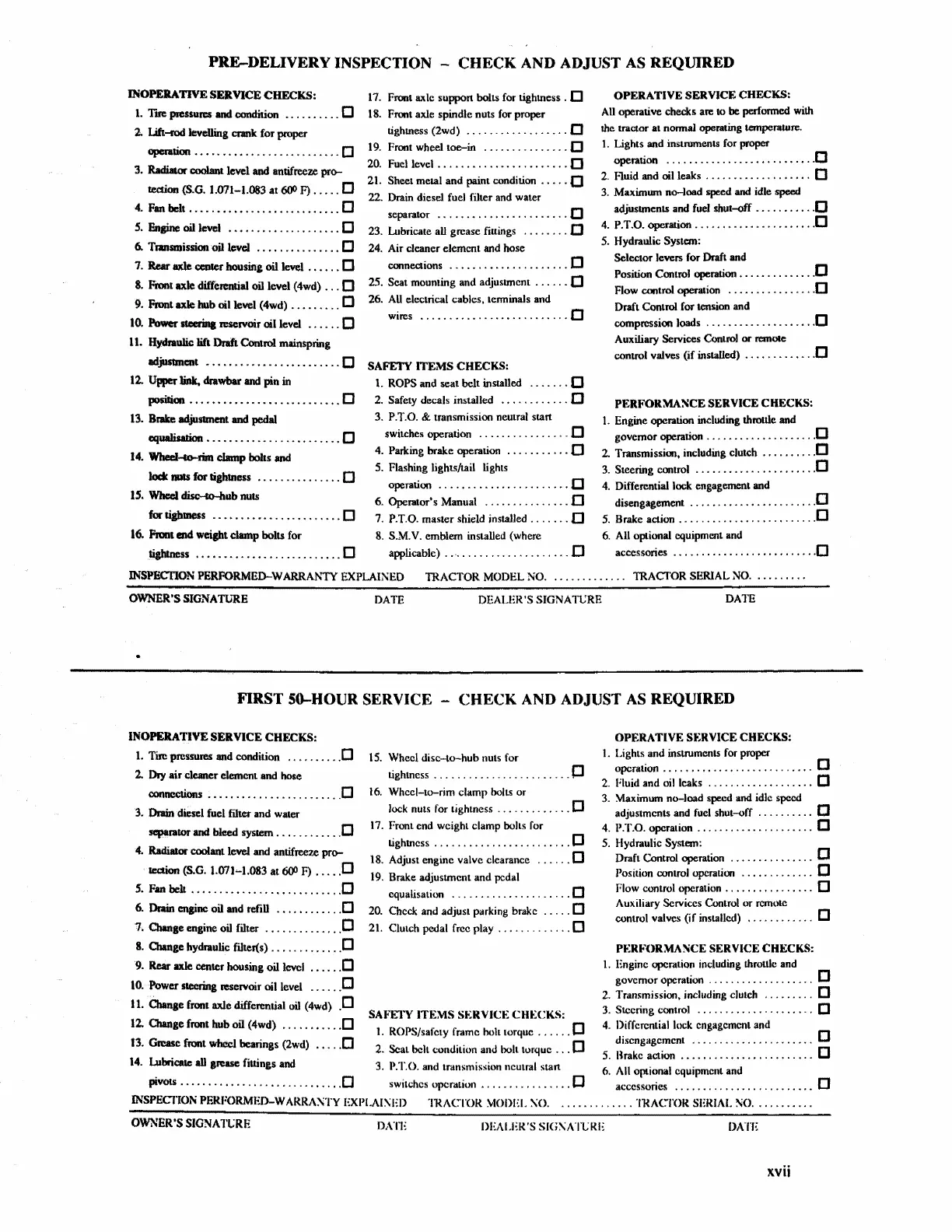

FIRST

SO-HOUR SERVICE

CHECK

AND ADJUST

AS

REQUIRED

INOPERATIVE SERVICE

CHECKS:

1.

Tire pressures

and

condition

..••......

D

15.

Wheel

disc-to-hub

nuts for

2.

Ory

air

cleaner element and hose

tightness

........................

CJ

connections

....•...................

0

16.

Wheel-to-rim

clamp

bolts

or

3.

Drain

diesel fuel filter and water

lock nuts for Lightness

.............

0

separator and bleed system

..........•.

CJ

4.

Radial.Or

coolant level and antifreeze

pro-

tection (S.G.

1.071~1.083

at

WI

F)

.....

0

5.

Fan

bek

...........................

CJ

17. Front end weight

clamp

bolts for

tightness

........................

0

18. Adjust engine valve clearance

......

CJ

19.

Brake adjustment

and

pedal

equalisati<m

..................

-

..

a

6.

Drain

engine

oil and refill

............

D

20.

Check and adjust parking brake

.....

0

7. Change engine oil filter

..............

0

21.

Clutch pedal free play

.............

0

8.

Oiange hydraulic filter(s)

.............

0

9.

Rear

axle

cenler

housing oil level

......

CJ

10. Power steering reservoir oil level

......

CJ

11.

Oiange

front

a:xle

differential oil (4wd)

.D

12.

Change front

hub

oil (4wd)

...........

CJ

13.

GR':BSc

front

wltcel

bearings (2wd)

.....

D

SAFETY

ITEMS

SERVICE

CHECKS:

1.

ROPS/safoty frame bolt torque

......

CJ

2. Scat belt condition and bolt torque

...

0

14. Lubricate

all

grease fittings and 3. P.T.O. and transmission neutral start

OPERATIVE

S1':RVICE

CHECKS:

I. Lights

and

instruments for proper

operation

...........................

a

2. Fluid

and

oil leaks . . . . . . . . . . . • . . . . . . . D

3.

~aximum

no-load

speed and idle speed

adjustments and fuel shut--uff

..........

CJ

4.

p:r.o. operation

.....................

a

5.

Hydraulic System:

Draft Control operation . . . . . . . . . . . . . . . D

Position control operation . . . . . . . . . . . . . 0

Flow control operation . . . . . . . . . . . . . . . . 0

Auxiliary Services Control or remote

control valves

(if

installed)

............

a

PERFORMANCE

SI<:RVICE

CHECKS:

1.

Engine opcnllion including throttle and

governor

operation -. . . . . . . . . . . . . . . . . . a

2. Transmission, including clutch

.........

0

3. Steering control . . . . . . . . . . . . . . . . . . . . C

4.

Differential luck engagement and

disengagement . . . . . . . . . . . . . . . . . . . . . . a

5.

Hrake action

........................

0

6. All optional equipment and

pivots . . . . . . •

.....................

D switches operation

................

D accessories

.........................

D

INSPECl'ION

PERFORMED-WARRA~TY

EXPl.Al~ED

TRACTOR

'.VIODEI.

'.'\O.

.

............

TRACTOR SERIAL

~O

..........

.

OWNER'S

SIGNA

Tt:RF.

DATE

DEALER'S

SIG~ATt;RE

DATE

xvii

Loading...

Loading...