CONTROLS, INSTRUMENTS

AND

OPERATION·--

OM499

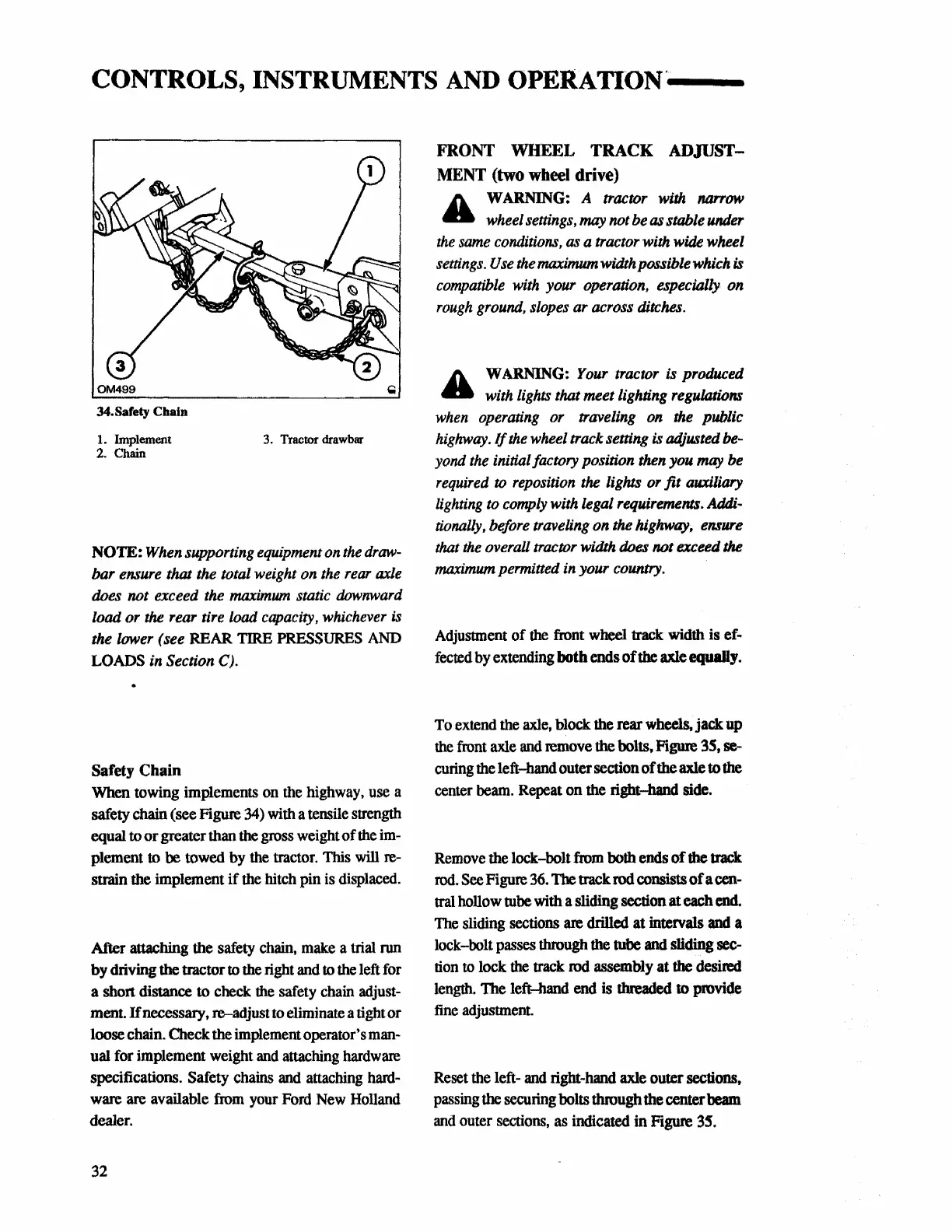

34.Safety Chain

1. hnplement 3. Tractor drawbar

2.

Chain

NOTE:

When

supporting

equipment

on

the

draw-

bar

ensure

that the total weight

on

the

rear

axle

does

not exceed

the

maximum

static

downward

load or

the

rear tire

load

capacity,

whichever

is

the lower (see REAR TIRE PRESSURES

AND

LOADS

in

Section

C).

Safety

Chain

When towing implements

on

the highway,

use

a

safety chain (see Figure 34) with a tensile strength

equal to

or

greater than the gross weight

of

the

im-

plement

to

be

towed by

the

tractor. This will

re-

strain

the

implement

if

the hitch pin is displaced.

After

attaching the safety chain, make a trial run

by driving the tractor to the right and to the left for

a short distance

to

check the safety chain adjust-

ment.

ff

necessary, re-adjust

to

eliminate a tight or

loose chain. Check the implement operator's man-

ual for implement weight

and

attaching

hardware

specifications. Safety chains and attaching hard-

ware are available from your Ford New

Holland

dealer.

32

FRONT WHEEL TRACK ADJUST-

MENT

(two wheel drive)

A

WARNING:

A tractor

with

Mn'OW

4lla wheel

settings,

may

not

be

as

stable

under

the

same

conditions,

as

a tractor

with

wide

wheel

settings.

Use

the

maximum

width possible

which

is

compatible

with

your operation, especially

on

rough

ground,

slopes

ar across

ditches.

A

WARNING:

Your

tractor

is produced

4lla

with

lights

that meet lighting

regulations

when

operating

or traveling

on

the

public

highway.

If

the

wheel

track setting

is

adjusted

be-

yond

the

initial factory position

then

you

may

be

required

to

reposition

the

lights

or fit auxiliary

lighting

to

comply

with

legal

requirements.

Addi-

tionally,

before

traveling

on

the

highway,

ensure

that

the

overall

tractor

width

does

not exceed the

maximum

permitted

in

your

country.

Adjustment

of

the front wheel track width is ef-

fected

by extending both ends

of

the axle equally.

To extend the axle, block the rear wheels, jack up

the front axle

and

remove the bolts, Figure 3S,

se-

curing

the left-hand outer section

of

the axle to the

center beam. Repeat on the right-band side.

Remove

the lock-bolt from both ends

of

the

track

rod.

See

Figure

36.

The

track rod consists

of

a cen-

tral

hollow tube with a sliding section at each

end.

The

sliding sections

are

drilled at intervals and a

lock-bolt

passes

through

the

tube

and

sliding sec-

tion

to

lock the track rod assembly

at

the

desired

length. The left-hand

end

is

threaded

to

provide

fine adjustment.

Reset the left- and right-hand

axle outer sections,

passing

the

securing

bolts through the center beam

and

outer sections, as indicated in Figure 35.

Loading...

Loading...