--------------SECTION

A

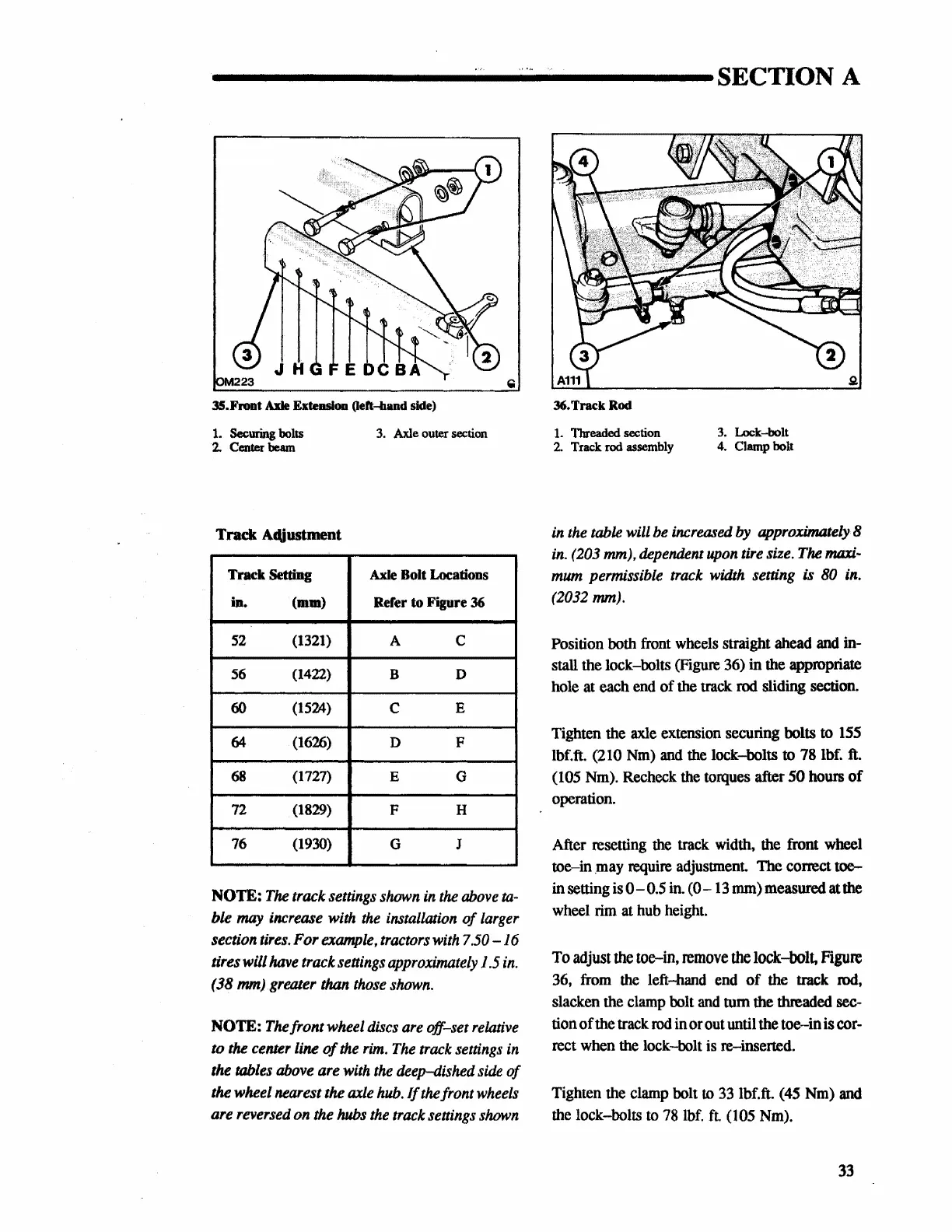

35.Front

Axle Extension (left-band side)

1. Securing bolts

3.

Axle

outer section

2. Center beam

Track Adjustment

Track Setting

Axle

Bolt Locations

in.

(mm)

Refer

to

Figure 36

52

(1321)

A

c

56

(1422)

B

D

60

(1524)

c

E

64

(1626)

D

F

68

(1727)

E

G

72

(1829)

F H

76

(1930)

G J

NOTE:

The

track settings

shown

in

the

above

ta-

ble

may

increase with

the

installation

of

larger

section

tires.

For

example,

tractors

with

7.50-16

tires will

have

track

settings

approximately

1.5

in.

( 38 mm)

.greater

than

those

shown.

NOTE:

The

front wheel

discs

are

off-set

relative

to

the

center line

of

the

rim.

The

track

settings

in

the

tables

above

are

with

the

deep-dished

side

of

the wheel nearest the

axle

hub.

If

thefrontwheels

are reversed on the

hubs

the

track settings

shown

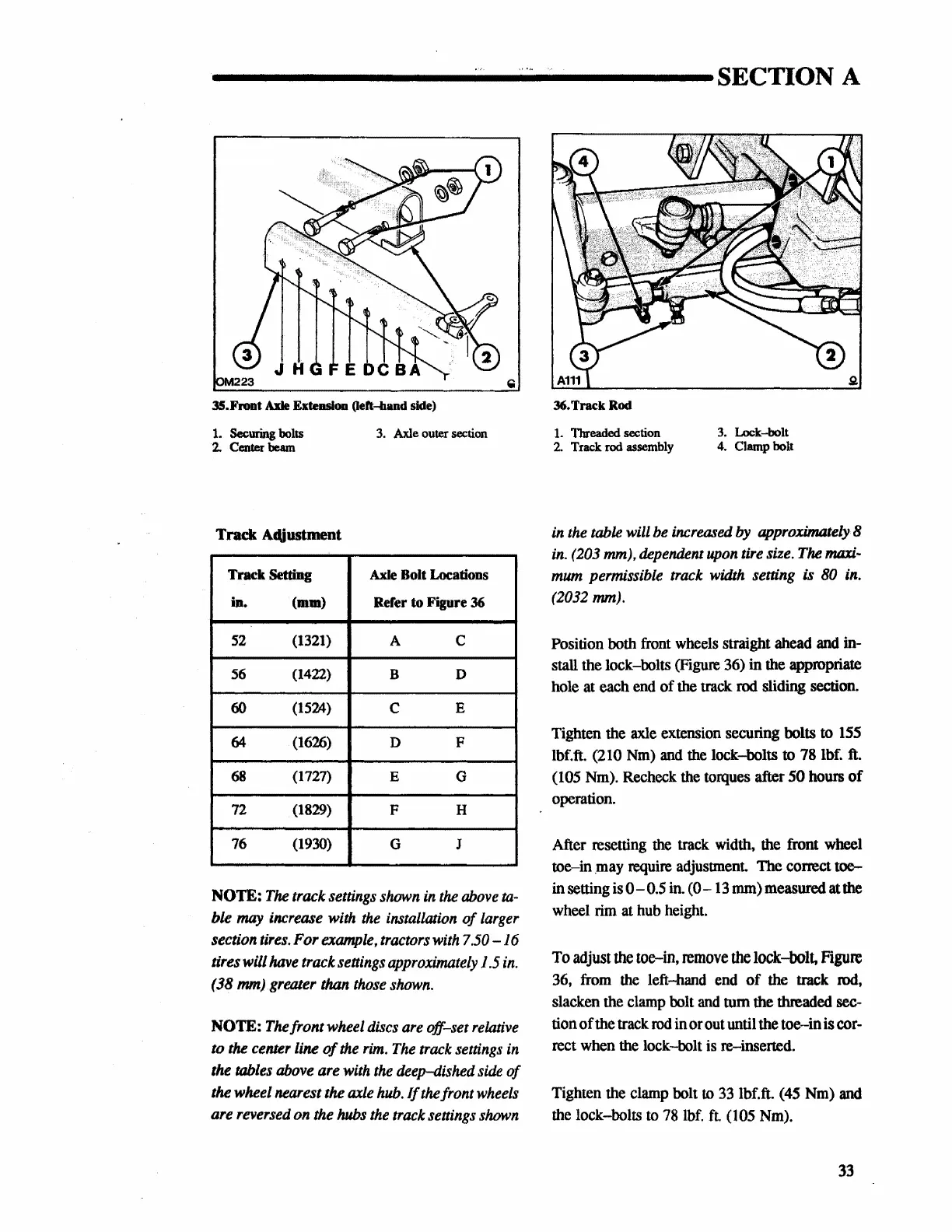

36.

Track

Rod

1.

Threaded section

3.

Lock-bolt

2.

Track rod

assembly

4.

Clamp bolt

in

the

table will

be

increased

by

approximately 8

in.

(203

mm), dependent

upon

tire size.

The

maxi-

mum

permissible

track

width

setting is 80

in.

(2032 mm).

Position both front wheels straight ahead and in-

stall the lock-bolts (Figure 36)

in

the appropriate

hole at each end

of

the track rod sliding section.

Tighten the axle extension securing bolts

to

155

!bf.ft.

(210 Nm) and the lock-bolts to 78 lbf. ft.

(105 Nm). Recheck the torques after

50

hours

of

operation.

After resetting the track width, the front wheel

toe-in

.may require adjustment.

The

correct

toe-

in

sening is

0-0.5

in.

(0-13

mm) measured at the

wheel rim at hub height.

To

adjust

the

toe-in,

remove

the

lock-bolt,

Figure

36, from the left-hand end

of

the track rod,

slacken the clamp bolt and

tum

the

threaded

sec-

tion

of

the track rod

in

or

out until the

toe-in

is

cor-

rect when the lock-bolt is re-inserted.

Tighten the clamp bolt

to

33 lbf.ft. (45 Nm) and

the lock-bolts to 78 lbf.

ft.

(105 Nm).

33

Loading...

Loading...