---------------SECTION

B

EVERY 1200 HOURS

or

2 YEARS (whichever occurs first)

carry

out the following:

'9.

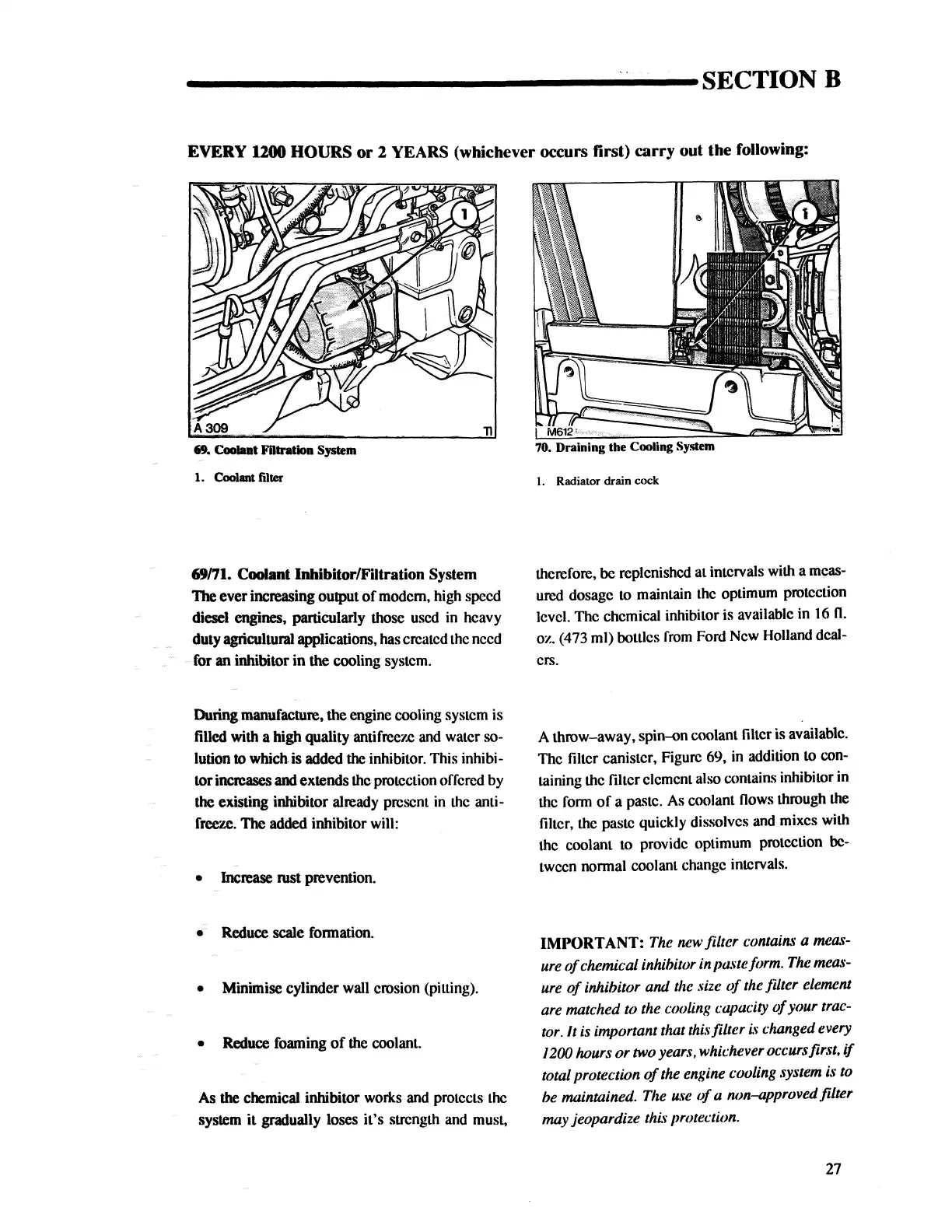

Coolant F'lltntlon System

1. Coolant filter

69/71. Coolant Inhibitor/Filtration System

1be

ever

increasing ouaput

of

modem, high speed

diesel

engines, particularly those used

in

heavy

duty agricultural applications,

ha.~

created the need

for

an

inhibitor

in

the

cooling system.

During_manufaclure,

the

engine cooling system is

filled

with a high quality antifrce7.e and water so-

lution

to

which

is

added

the inhibitor. This inhibi-

tor

increases and

extends

the

protection offered

by

the

existing inhibitor already present in the anti-

freeze.

The

added

inhibitor will:

• Increase rust prevention.

• Reduce scale fonnation.

• Minimise

cylinder

wall erosion (pitting).

• Reduce foaming

of

the coolant.

As

the

chemical inhibitor works and protects the

system

it

gradually loses

it's

strength and must,

,M612-"--""

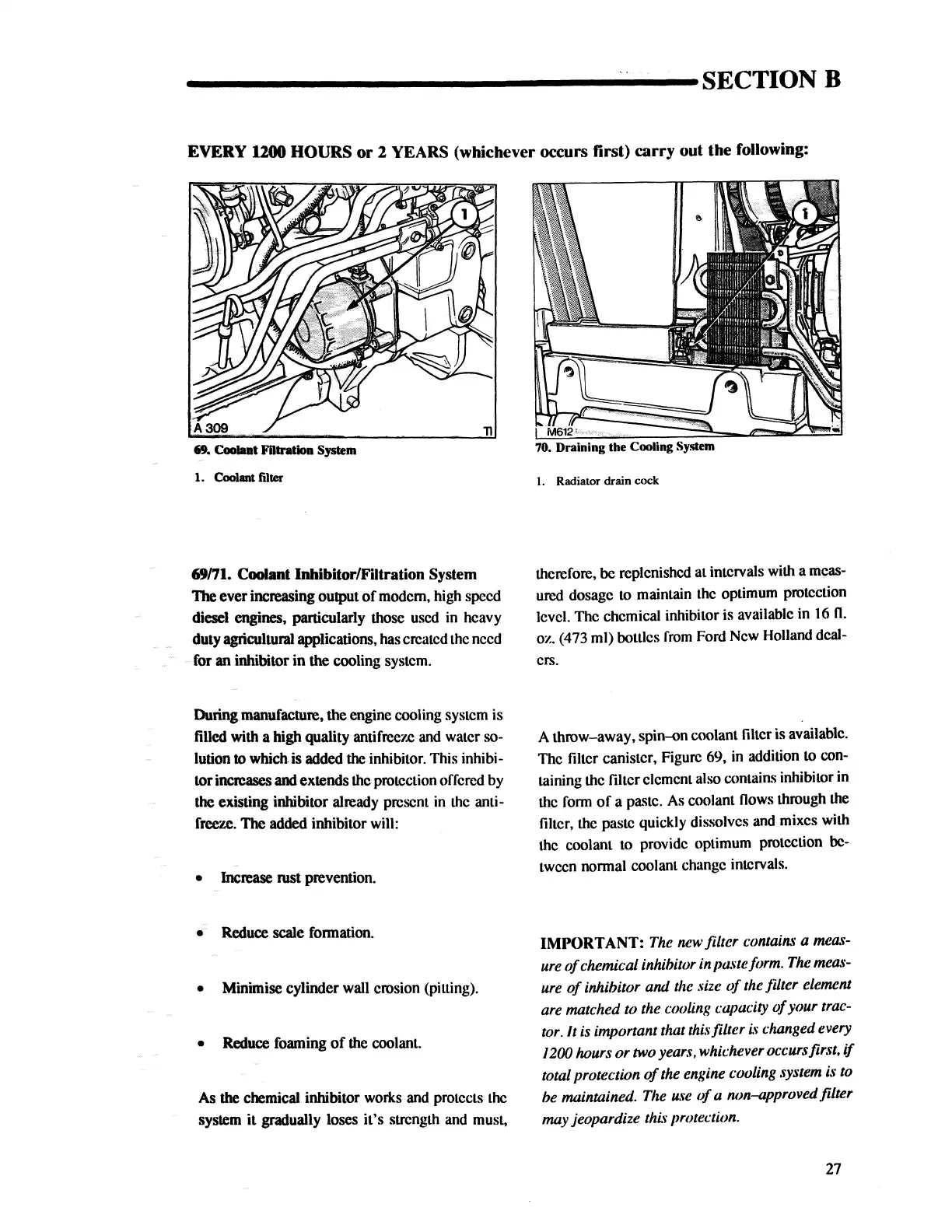

70. Draining the Cooling System

1.

Radiator drain cock

therefore, be replenished

at

intervals with a meas-

ured dosage

to maintain the optimum protection

level.

The

chemical inhibitor

is

available in 16 fl.

07..

(473

ml)

bottles from Ford New Holland deal-

ers.

A

throw-away,

spin-<>n

coolant filter is available.

The

filter canister, Figure

69,

in addition to con-

taining the filter clement also contains inhibitor in

the form

of

a

pa.~te.

As coolant flows through the

filter, the

paste quickly dissolves and mixes with

the coolant

to

provide optimum protection be-

tween normal coolant change intervals.

IMPORT

ANT:

The

new

filter contains a

meas-

ure

of

chemical inhibitor

in

paste

form.

The

mea.~

ure

of

inhibitor and

the

.~ize

of

the filter element

are

matched to the

c()()ling

capacity

of

your

trac-

tor.

It

is

important that

this

filter

is

changed

every

1200

hours

or

two

years, whichever occurs first,

if

total protection

of

the

engine

C()()ling

system is to

be maintained.

The

use

of

a non-approved filter

may

jeopardize this protection.

27

Loading...

Loading...