LUBRICATION AND

MAINTENAN·c·E'~._

___

_

GENERAL MAINTENANCE

The

following

pictures

and

text

detail

service or

adjustment procedures that

are

not

required

to

be

carried out on a routine

basis.

72. Engine

Coolant

In

the

event of a loss of

coolant,

for.

example

a

leaking

hose

or gasket, it

is

important

to

firstly,

correct

the

leak

and

secondly,

top

up

with

a pre-

mixed

solution of

water,

antifreeze

and

inhibitor

of

the

correct proportions.

Ford

New

Holland

recommends

that

a solution of

50%

clean water and

50%

antifreeze,

no

matter

what

degree

of

freeze

protection is

required,

be

pre-mixed with

5%

inhibitor

and

used

as

a top-up

solution. The inhibitor

is

available

from

Ford

New

Holland dealers under

the

part

number

FW-15.

It

is supplied in 16 fl.

oz.

(473

ml)

bottles

and

when

this

amount

is

mixed

with

2.4 U.S.

Gals.

(2.0

Imp.

Gals - 9.0

litres)

of water/antifreeze

solution it

will

provide

the

correct inhibitor

charge.

Always

keep

this pre-mixed

solution

in

a specially

marked container for

top-up

purposes

and

always

investigate

the

cause

of

leakage

and

repair

prop-

erly. Do not

use

anti-leak

additives.

A WARNING: Inhibitor

solution

is

irri-

tating to

eyes

and

skin.

It

contains

buff-

ered potassium hydroxide.

• Avoid contact with

eyes

or prolonged and

re-

peated skin contact.

•

Wear

protective eyewear

when

using.

•

In

case

of

contact with

eyes,

flush

with

water

for

15

minutes and obtain

medical

attention.

•

Wash

skin with

soap

and water after

use.

•

Keep

out

of

reach

of

children.

30

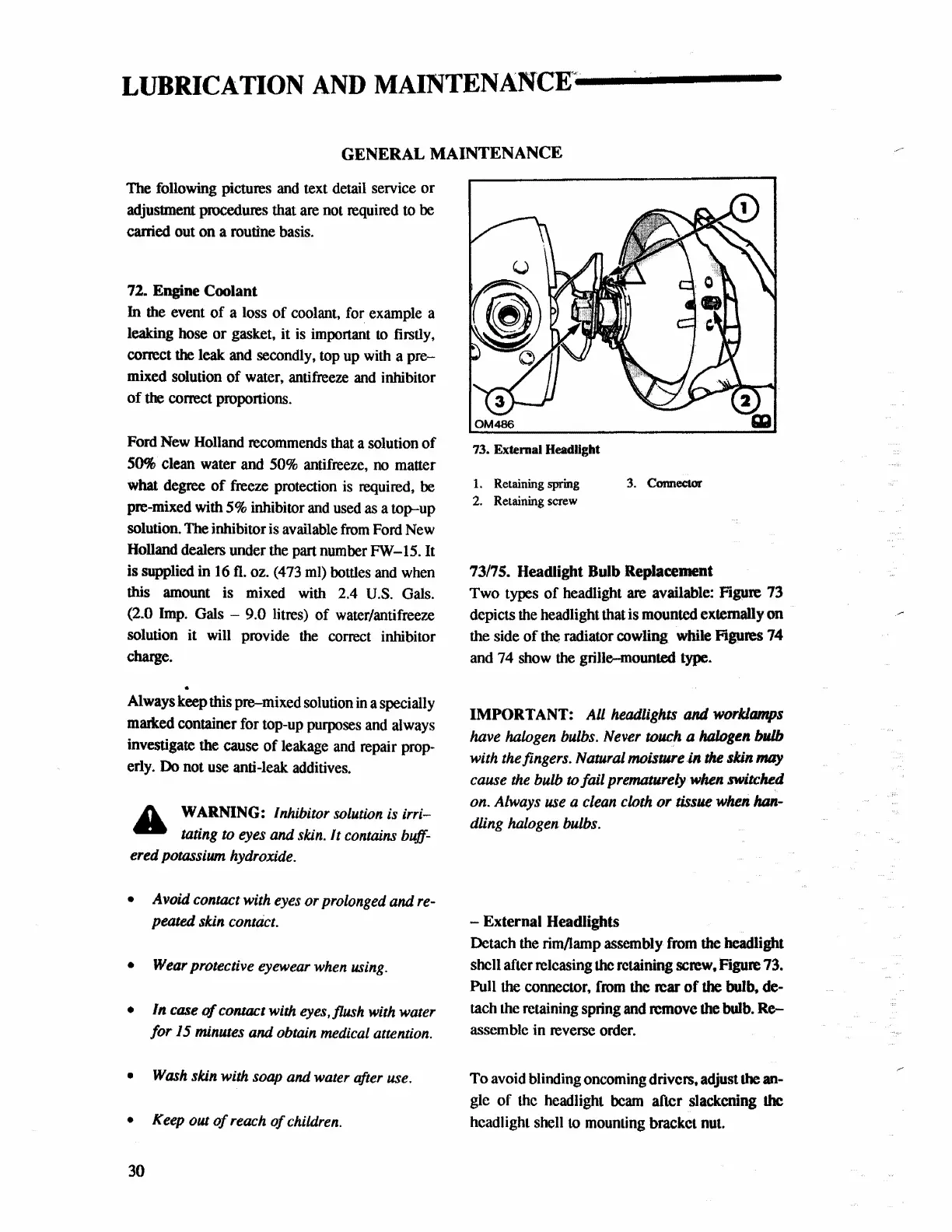

73. External Headlight

1.

Retaining spring

3.

Cmmector

2.

Retaining screw

73/75. Headlight Bulb Replacement

Two

types

of

headlight

are

available: Fipare

73

depicts

the

headlight that

is

mounted externally on

the side

of

the

radiator cowling while

Figures

74

and

74

show

the

grille-mounted

type.

IMPORTANT: All headlights

and

worklamps

have halogen bulbs.

Never

touch a halogen bulb

with the fingers. Natural moisture

.in

the

skin

may

cause

the

bulb to fail prematurely when switched

on. Always

use

a

clean

cloth

or

tissue

when han-

dling halogen bulbs.

- External Headlights

Detach

the

rim/lamp assembly

from

the

headlight

shell after releasing the

retaining

screw,

Figure

73.

Pull

the

connector,

from

the rear

of

the

bulb, de-

tach

the

retaining spring

and

remove

the

bulb.

Re-

assemble in reverse

order.

To

avoid

blinding oncoming drivers, adjust the an-

gle

of

the headlight beam after slackening lhc

headlight shell to

mounting

bracket

nut.

Loading...

Loading...