CONTROLS,

INSTRUMENTS

AND·OPERATION·-',,

....__

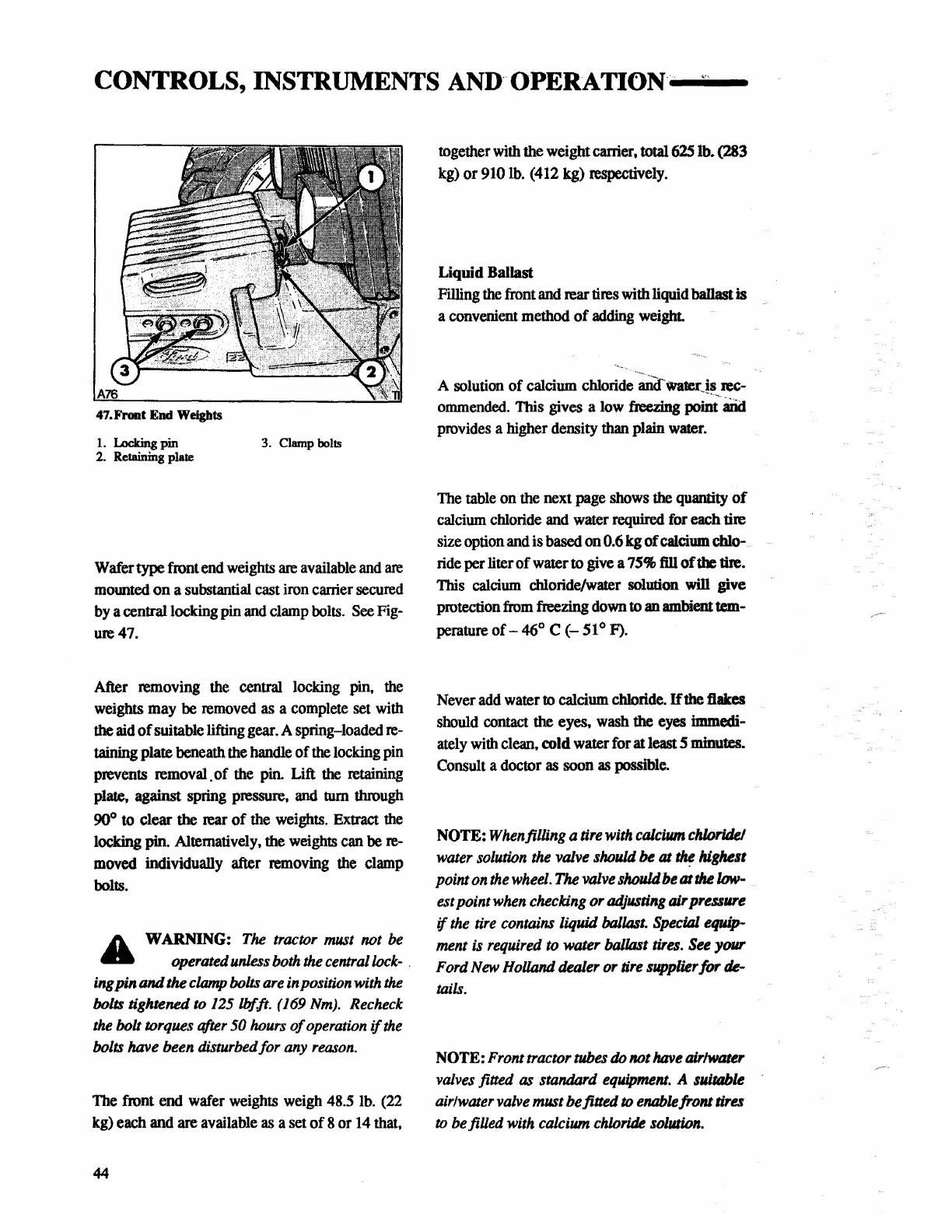

47.Front End Weights

1.

Locking

pin

3. Clamp bolts

2. Retaining plate

Wafer type front end weights

are

available and

are

mowited

on

a substantial cast iron carrier secured

by a central locking pin and clamp bolts.

See Fig-

ure

47.

After removing the central locking pin,

the

weights may

be

removed as a complete set with

the aid

of

suitable lifting gear. A spring-loaded

re-

taining plate beneath the handle

of

the locking pin

prevents removal.

of

the pin. Lift the retaining

plate, against spring pressure, and

tum through

90°

to clear

the

rear

of

the weights. Extract

the

locking pin. Alternatively, the weights can

be

re-

moved

individually

after

removing the clamp

bolts.

A WARNING:

The

tractor must not be

...

operated unless both

the

central

lock-

.

ing pin and the

clamp

bolts are in position with

the

bolts tightened

to

125

lbfft.

(169 Nm). Recheck

the bolt torques

qfter 50 hours

of

operation

if

the

bolts have been disturbed for any

reason.

The front end wafer weights weigh

48.5

lb.

(22

kg) each and

are

available

as

a

set

of

8 or

14

that,

44

together with the weight canier, total

625

lb. (283

kg)

or

910

lb.

(412 kg) respectively.

Liquid

Ballast

Filling the front and rear tires with liquid

ballast

is

a convenient method

of

adding weight

A solution

of

calcium chloride

ancfwaterJs

rec-

ommended. This gives a low

freezing

pohtt

8rid

provides a higher density than plain water.

The table on the next page shows the quantity

of

calcium chloride and water

required.

for each tire

size option

and

is

based

on

0.6

kg

of calcium chlo-

ride per liter

of

water to give a

75%

fill

of

the

tire.

This calcium chloride/water solution will

give

protection

from

freezing down to an ambient

t.em-

perature

of-

46° C

(-

51° F).

Never add water to calcium chloride.

If

the flakes

should contact the

eyes,

wash the

eyes

immedi-

ately with clean, cold water for

at

least 5 minub:s.

Consult a doctor

as

soon

as

JX>Ssible.

NOTE:

Whenfilling a

tire

with

calcium

chloride/

water

solution

the

valve slwuld be

at

~

hi.ghest

point on

the

wheel.

The

valve should be at the low-

est

point when

checking

or adjusting air pressure

if

the

tire

contains

liquid ballast.

Special

equip-

ment

is

required

to

water ballast tires. See

yow

Ford

New

Holland dealer or tire supplier for de-

tails.

NOTE:

Front tractor tubes do not have air/water

valves fitted as standard

equipment.

A

suitable

air/water valve must be fitted

to

enable front tires

to be filled with calcium chloride

solution.

Loading...

Loading...