7-64 PQM Power Quality Meter GE Power Management

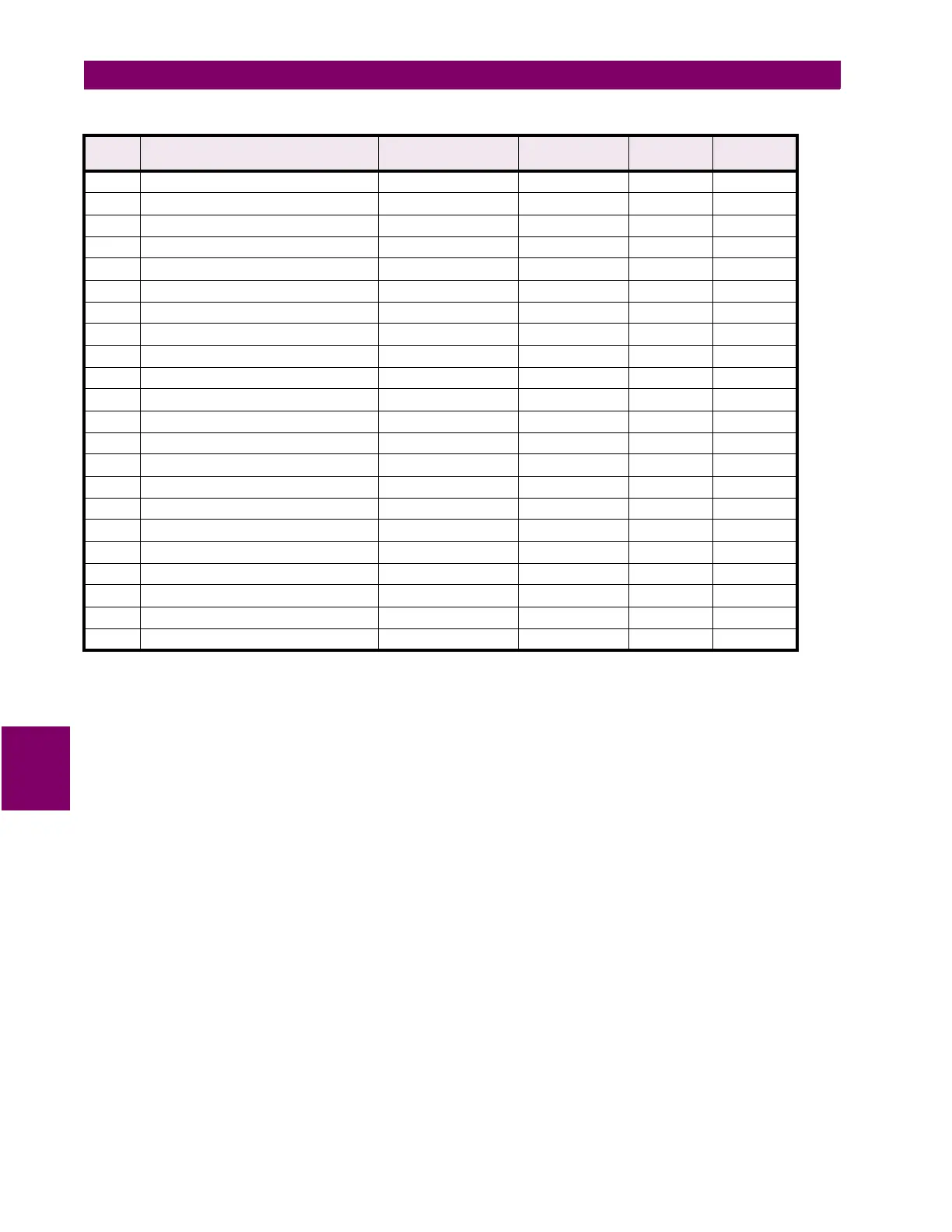

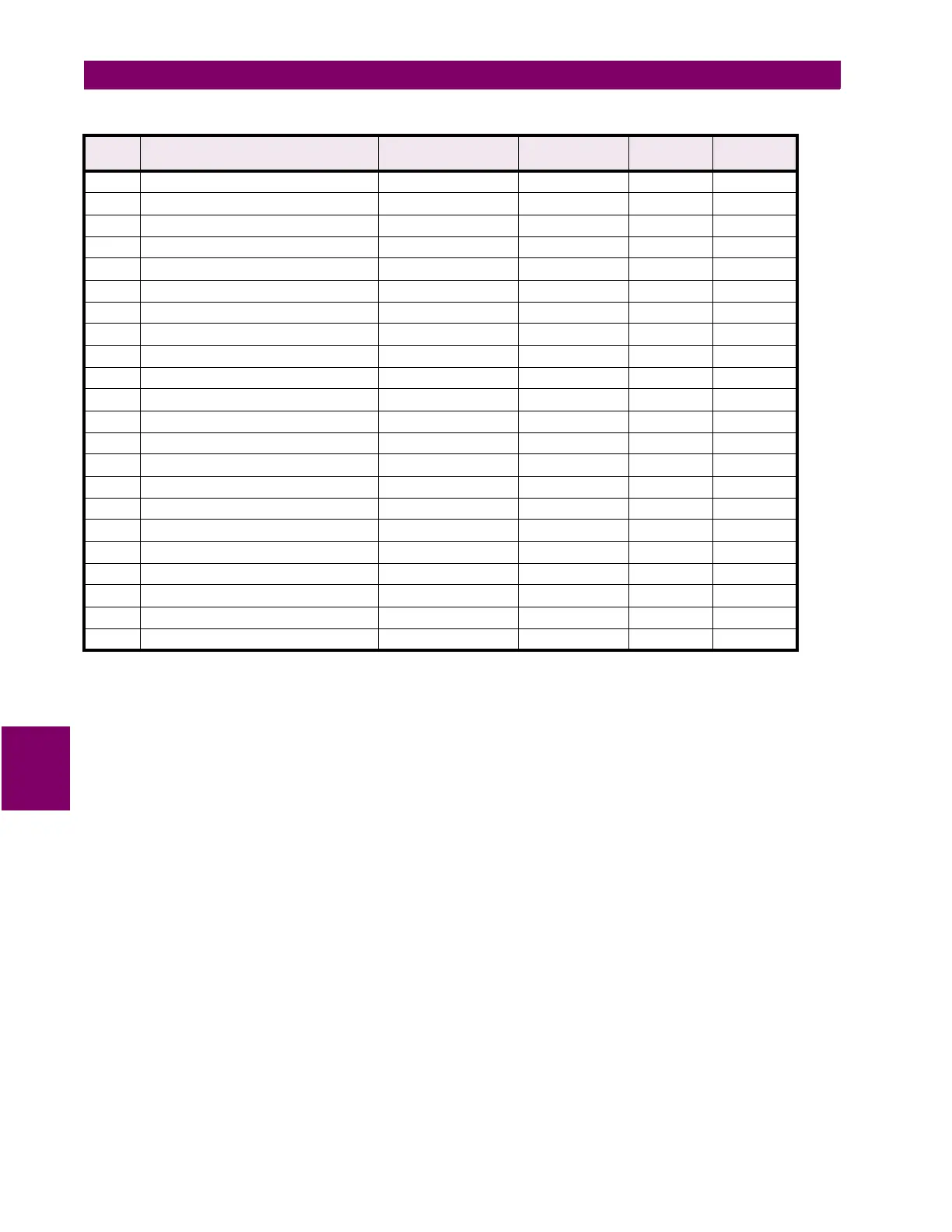

7.3 MODBUS MEMORY MAP 7 MODBUS COMMUNICATIONS

7

38 3 Phase -kWh Used 0 to 65400 1 kWh 0

39 3 Phase -kvarh Used 0 to 65400 1 kvarh 0

40 3 Phase kVAh Used 0 to 65400 1 kVAh 0

41 Phase A Current Demand 0 to 7500 1 A 0

42 Phase B Current Demand 0 to 7500 1 A 0

43 Phase C Current Demand 0 to 7500 1 A 0

44 Neutral Current Demand 0 to 7500 1 A 0

45 3 Phase kW Demand –32500 to +32500 1 kW 0

46 3 Phase kvar Demand –32500 to +32500 1 kvar 0

47 3 Phase kVA Demand 0 to 65400 1 kVA 0

48 3 Phase Current THD 0 to 1000 1 0.1 × %0

49 Three Phase Voltage THD 0 to 1000 1 0.1 × %0

50 Phase A Current THD 0 to 1000 1 0.1 × %0

51 Phase B Current THD 0 to 1000 1 0.1 × %0

52 Phase C Current THD 0 to 1000 1 0.1 × %0

53 Voltage Van THD 0 to 1000 1 0.1 × %0

54 Voltage Vbn THD 0 to 1000 1 0.1 × %0

55 Voltage Vcn THD 0 to 1000 1 0.1 × %0

56 Voltage Vab THD 0 to 1000 1 0.1 × %0

57 Voltage Vbc THD 0 to 1000 1 0.1 × %0

58 Neutral Current THD 0 to 1000 1 0.1 × %0

59 Serial Control –32500 to +32500 1 --- 0

Table 7–12: ANALOG OUTPUT PARAMETER RANGE FOR SERIAL PORTS (Sheet 2 of 2)

NO. ANALOG OUT PARAMETER RANGE STEP UNITS/

SCALE

DEFAULT

*

Due to the fact that –0 and +0 both exist for power factor, the value stored in the PQM serial register is the

opposite of the value shown on the display.

Example: If the range 0.23 lead (–0.23) to 0.35 lag (+0.35) is required, –77 (–100+23)and +65 (100–35) must

be sent.

Loading...

Loading...