6-16 PQM Power Quality Meter GE Power Management

6.6 POWER ANALYSIS 6 SOFTWARE

6

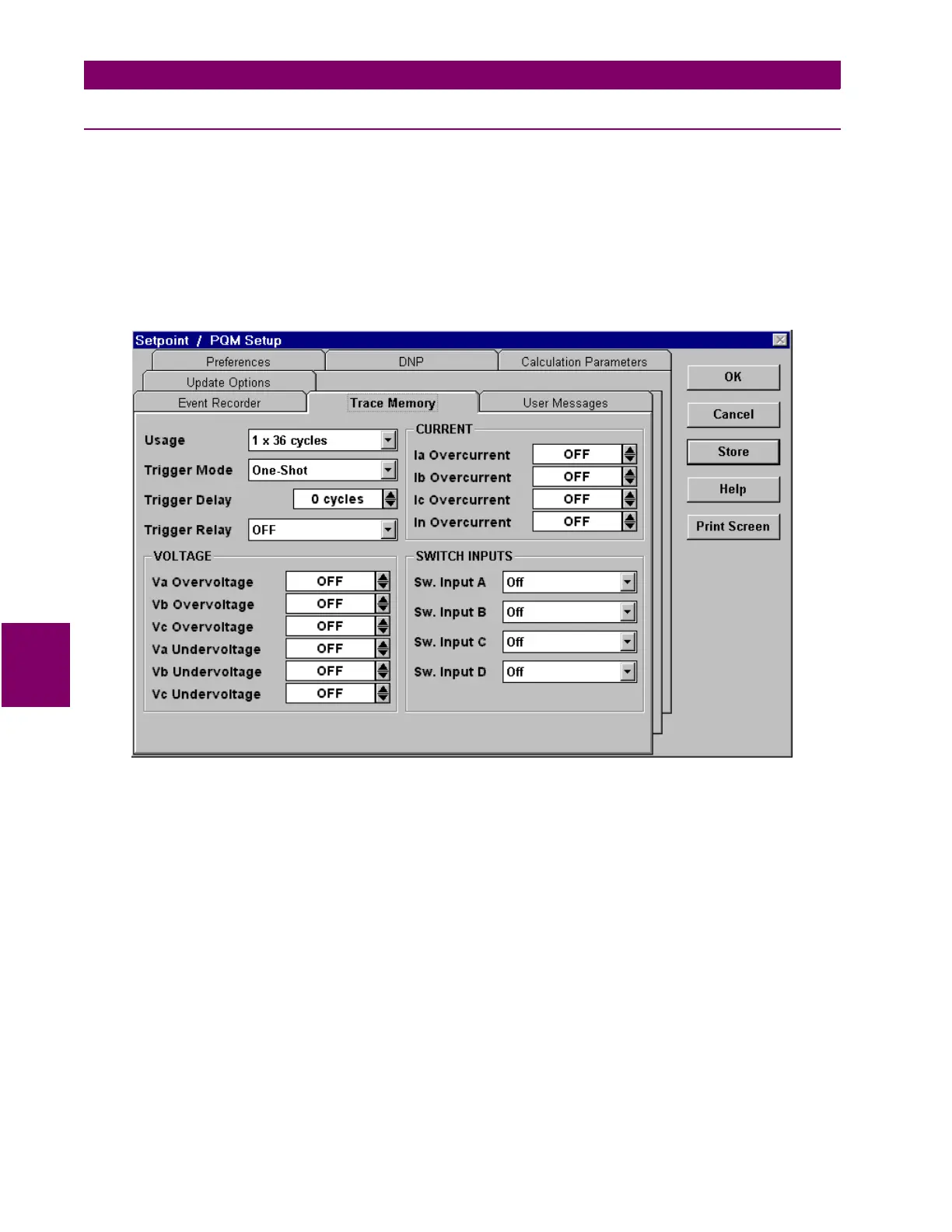

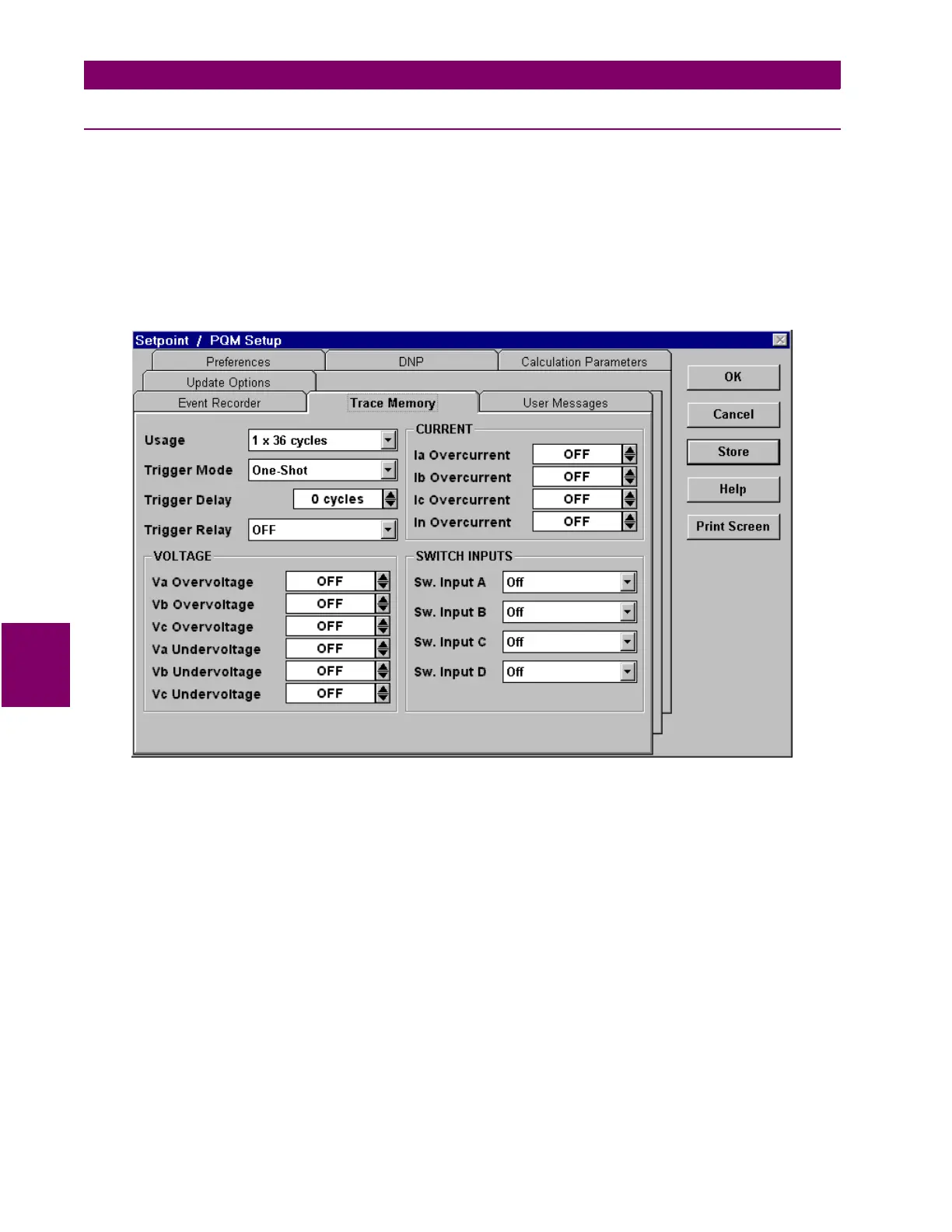

6.6.3 TRACE MEMORY

The trace memory feature allows the PQM to be setup to trigger on various conditions. The trace memory can

record maximum of 36 cycles of data (16 samples per cycle) for all voltage and current inputs simultaneously.

A Total Trace Triggers Counter has been implemented in the PQM Memory Map at Register 0x0B83. This reg-

ister will keep a running total of all valid Trace Memory Triggers from the last time power was applied to the

PQM. The Total Trace Triggers counter will rollover to 0 at 65536. The trace memory feature is implemented

into PQMPC as shown below.

1. Select the

Setpoint > PQM Setup

menu item to setup the trace memory feature. This launches the PQM

Setup dialog box shown below. Click on the

Trace Memory

tab to display the trace memory parameters.

The

Memory Usage

is set as follows:

•

1 x 36 cycles

: upon trigger, the entire buffer is filled with 36 cycles of data

•

2 x 18 cycles

: 2 separate 18-cycle buffers are created and each is filled upon a trigger

•

3 x 12 cycles

: 3 separate 12 cycle buffers are created and each is filled upon a trigger

If the

Trigger Mode

is set to

One-Shot

, then the trace memory is triggered once per buffer; if it is set to

Retrig-

ger

, then it automatically retriggers and overwrites the previous data.

The

Trigger Delay

delays the trigger by the number of cycles specified.

The

VOLTAGE

,

CURRENT

, and

SWITCH INPUTS

selections are the parameters and levels that are used to trig-

ger the trace memory.

Clicking

Store

sends the current settings to the PQM.

Loading...

Loading...