HEIDENHAIN iTNC 530 485

12.1 Execution of CAM programs

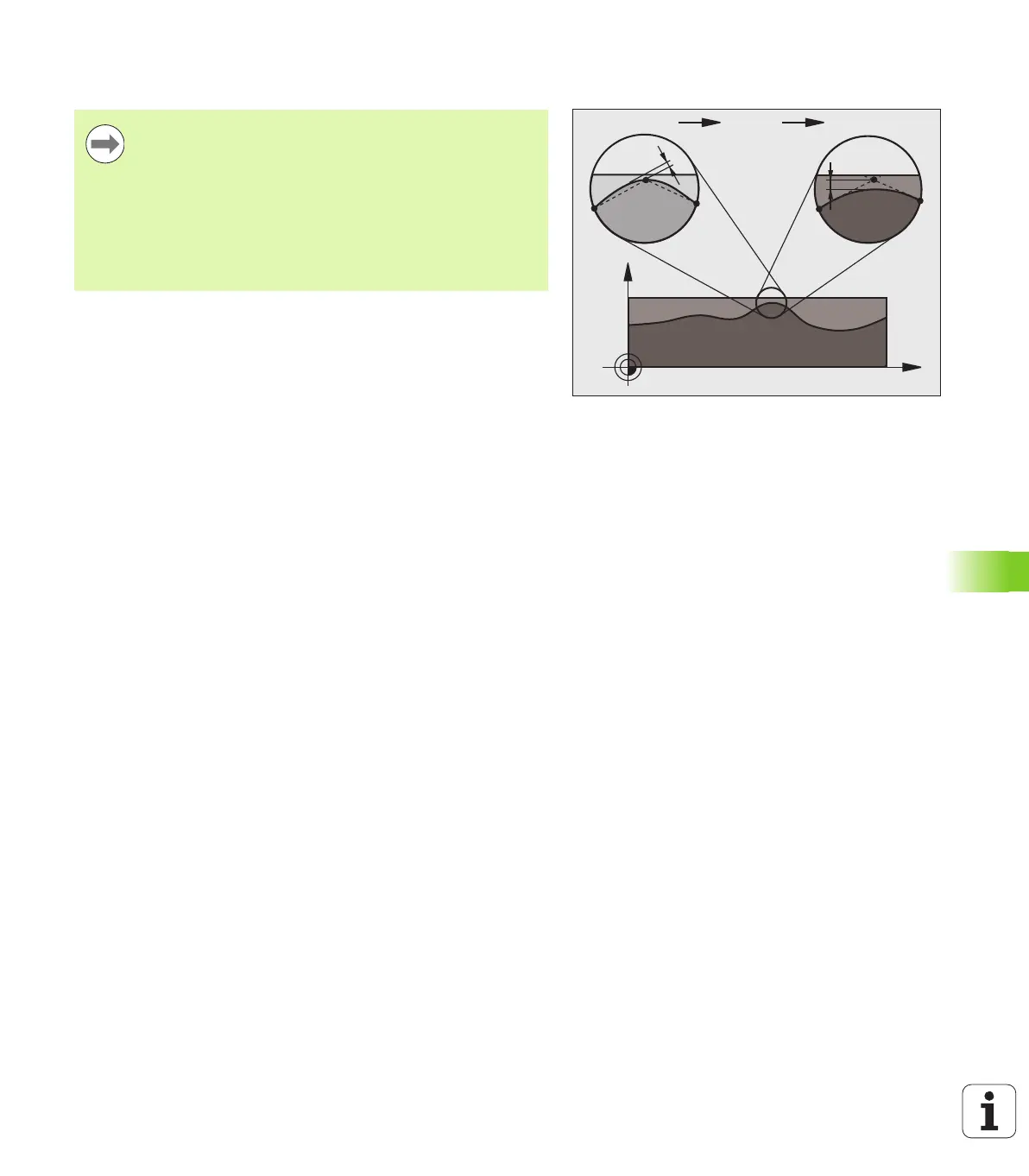

Please note the following for CAM programming

How to adapt the chord error in the CAM program, depending on the

machining:

Roughing with a preference to speed

Use higher values for the chord error and the appropriate

tolerance in Cycle 32. Both values depend on the oversize

required on the contour. Typical values for the tolerance in Cycle

32 are between 0.05 mm and 0.3 mm. A typical chord error in the

CAM program is between 0.004 mm and 0.030 mm. If a special

cycle is available on your machine, use the roughing mode. In

roughing mode the machine generally moves with high jerk values

and high accelerations

Finishing with a preference to high accuracy

Use smaller values for the chord error and an appropriately small

tolerance in Cycle 32. The data density must be high enough for

the TNC to detect transitions and corners exactly. Typical values

for the tolerance in Cycle 32 are between 0.002 mm and

0.006 mm. A typical chord error in the CAM program is between

0.001 mm and 0.004 mm. If a special cycle is available on your

machine, use the finishing mode. In finishing mode the machine

generally moves with low jerk values and low accelerations

Finishing with a preference to high surface definition

Use smaller values for the chord error and an appropriately large

tolerance in Cycle 32. The TNC then smoothes the contour more

exactly. Typical values for the tolerance in Cycle 32 are between

0.010 mm and 0.020 mm. Do not define the chord error in the

CAM program to a value greater than 0.005 mm. If a special cycle

is available on your machine, use the finishing mode. In finishing

mode the machine generally moves with low jerk values and low

accelerations

When defining roughing operations, make sure that the

sum of the chord error defined in the CAM system and

the tolerance from Cycle 32 is less than the defined

machining oversize. This ensures that no contour gouging

will occur.

When defining finishing operations, make sure that the

chord error defined in the CAM system is not set to

greater than 5 µm. In Cycle 32, use the appropriate

tolerance factor T of 1.3 to 5.

Loading...

Loading...