536 Programming: Execution of CAM Programs, Multi-axis Machining

12.7 Three-dimensional tool compensation (software option 2)

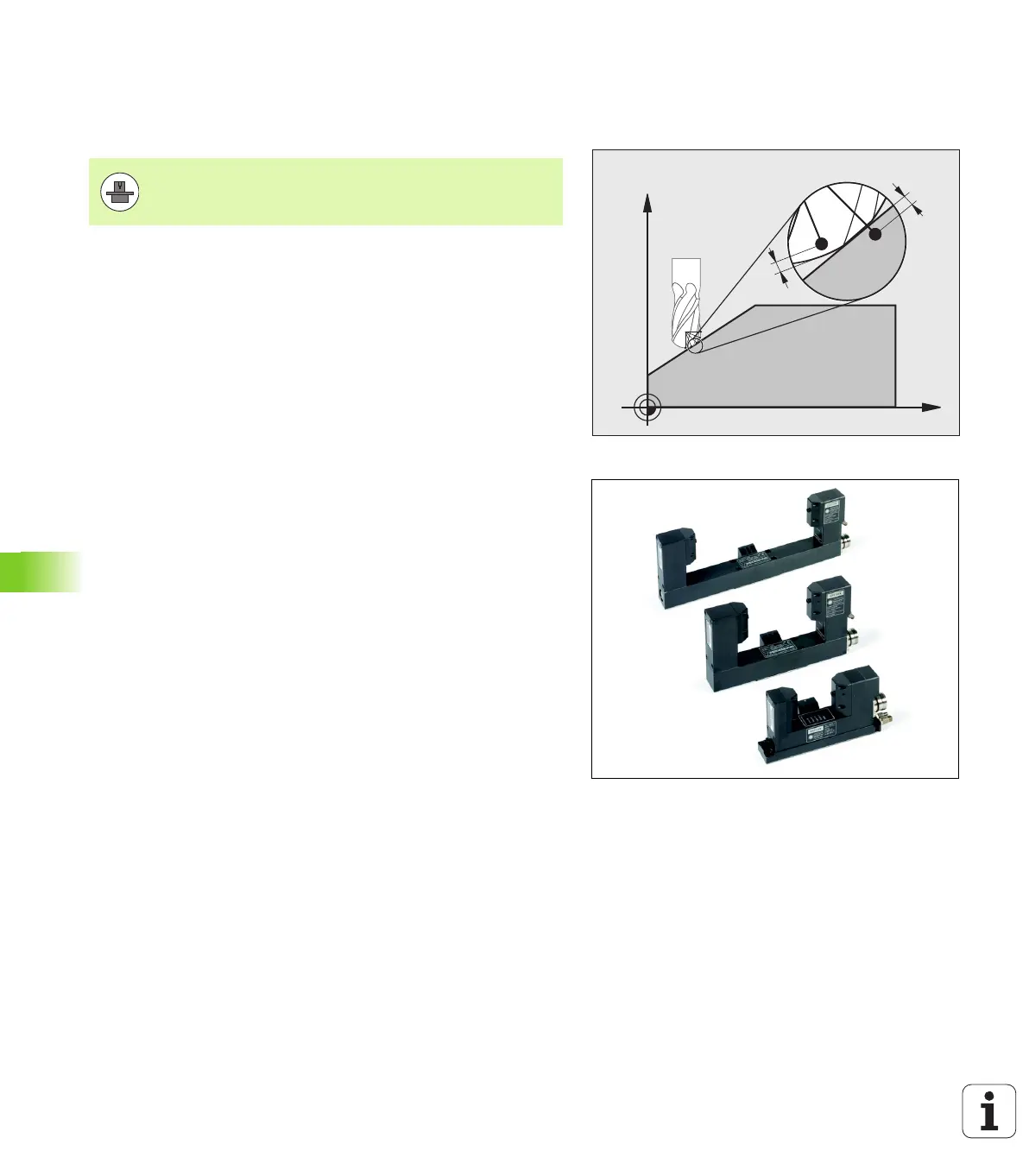

3-D tool radius compensation depending on the

tool’s contact angle (3D-ToolComp software

option)

The effective sphere radius of a radius cutter deviates from the ideal

form owing to the production process. The maximum form inaccuracy

is specified by the tool manufacturer; common error is between 0.005

and 0.01 mm.

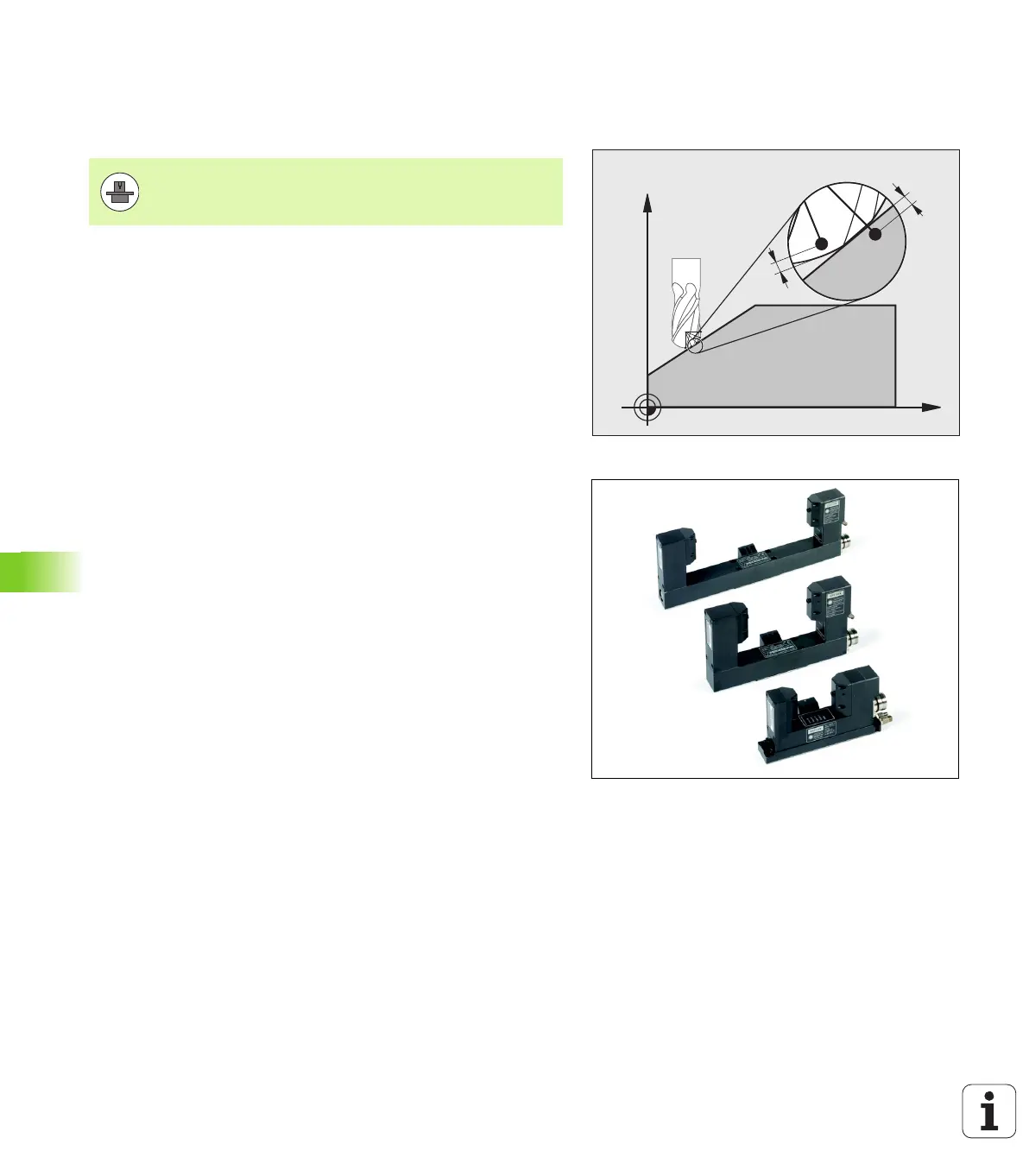

The form inaccuracy can be determined with a laser system and the

corresponding laser cycles on the TNC. It can then be saved as a

compensation value table. This table contains angle values and the

deviation from the nominal radius R2 measured on the respective

angle value.

The 3D-ToolComp software option enables the TNC to compensate

the value defined in the compensation value table depending on the

actual contact point of the tool.

Requirements

Software option 3D-ToolComp is enabled

Software option 2, 3-D machining is enabled

MP7680, bit 6 must be set to the value 1: The TNC takes R2 from

the tool table into account during tool length compensation

The DR2TABLE column in the tool table (TOOL.T) is enabled

(MP7266.42)

The tool was measured with the laser system and the

compensation value table is available in a directory under TNC:\.

Alternatively you can also create the compensation table manually

(see "Compensation-value table" on page 537)

The tool dimensions L, R and R2 are entered in the tool table

(TOOL.T)

The path name of the compensation value table for the tool to be

compensated is entered (without file extension) in the DR2TABLE

column of the tool table (TOOL.T) (see "Tool table: Standard tool

data" on page 182)

NC program: NC blocks with surface normal vectors are required

(see "NC program" on page 539)

Software option 2 is also required to be able to use

software option 92, 3-D ToolComp.

Loading...

Loading...