td2O724b

4. For lter replacement, refer to the

instruction for replacing the air

cleaner lter for every year.

To clean the lter, use only clean dry

compressed air on the inside of the

lter. Air pressure at the nozzle must

not exceed 2 kgf/cm² (29 psi). Main-

tain reasonable distance between

the nozzle and the lter.

EVACUATOR VALVE

Open the evacuator valve gab by

ngers once a week under ordinary

conditions or daily when used in du-

sty conditions to get rid of large parti-

cles of dust and dirt.

CHECKING FUEL LINES (U)

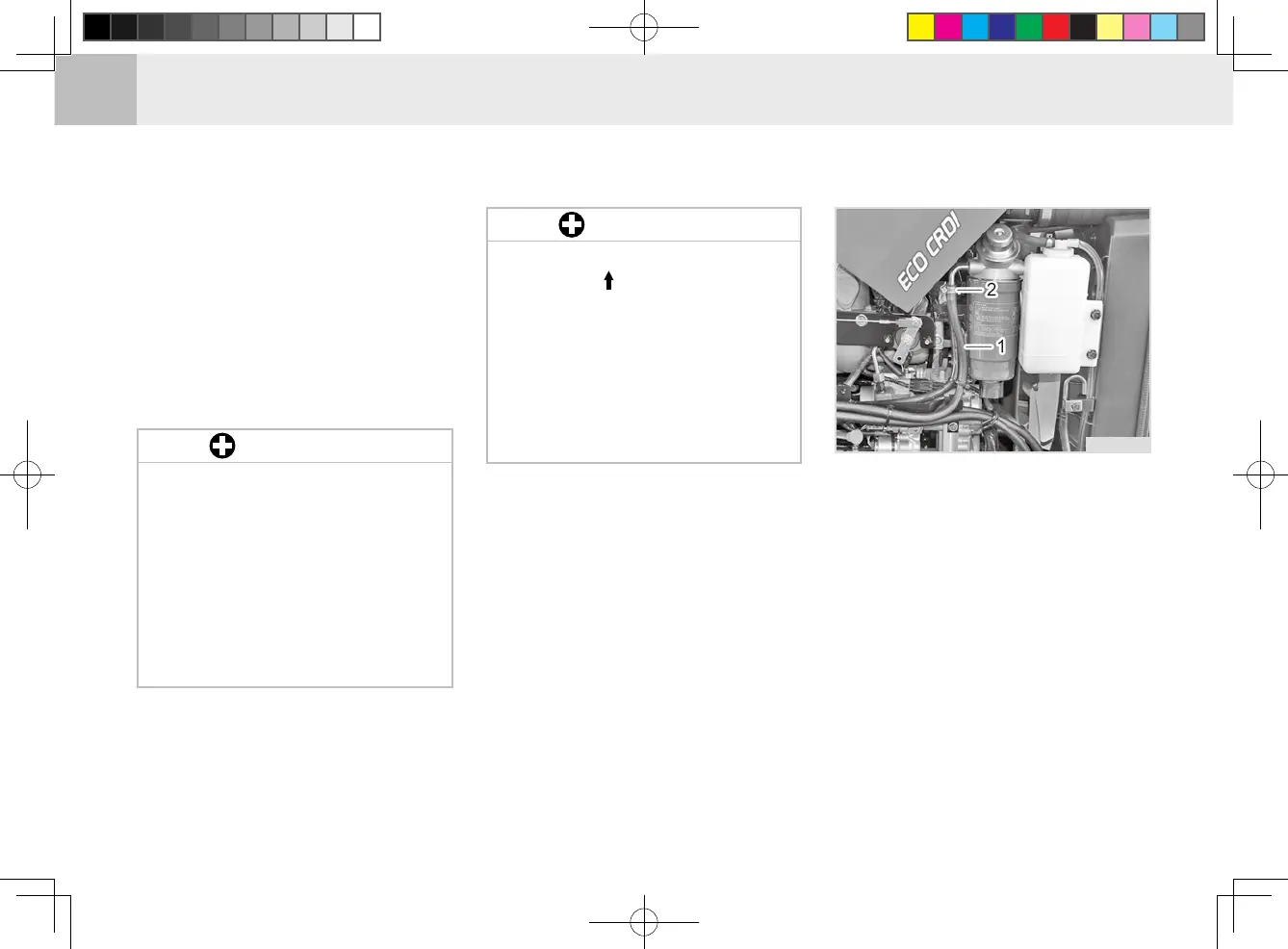

(1) Fuel Pipe (2) Fuel Hose Clamp

IMPORTANT

The air cleaner will only fulll

its function if it is correctly

and regularly maintained. A

poorly maintained air clea-

ner will mean loss of power,

excessive fuel consumption

and a reduction in engine life.

Do not run the engine with l-

ter element removed.

•

•

IMPORTANT

Be sure to ret the cover with

the arrow (on the rear of co-

ver) upright. If the cover is im-

properly tted, evacuator valve

will not function and dust will

adhere to the element. (Refer to

the instructions for replacing

the air cleaner filter for every

year in Chapter Maintenance.)

•

Although checking the fuel pipe

connection is recommended every

100 service hours, it should be done

every 6 months if operation does not

exceed 100 hours in 6 months.

1. If the hose clamps are loose, apply

a slight coat of lubricant onto the

threads and securely tighten it.

2. The fuel pipe is made of rubber and

ages regardless of period of servi-

ce. Change the fuel pipe together

with the hose clamps every two

years and securely tighten.

Loading...

Loading...