102

5�1

Maintenance, Items to be Checked, and Schedule

This section describes maintenance and items to be checked necessary to ensure use of DRYPRO

873 in optimum condition.

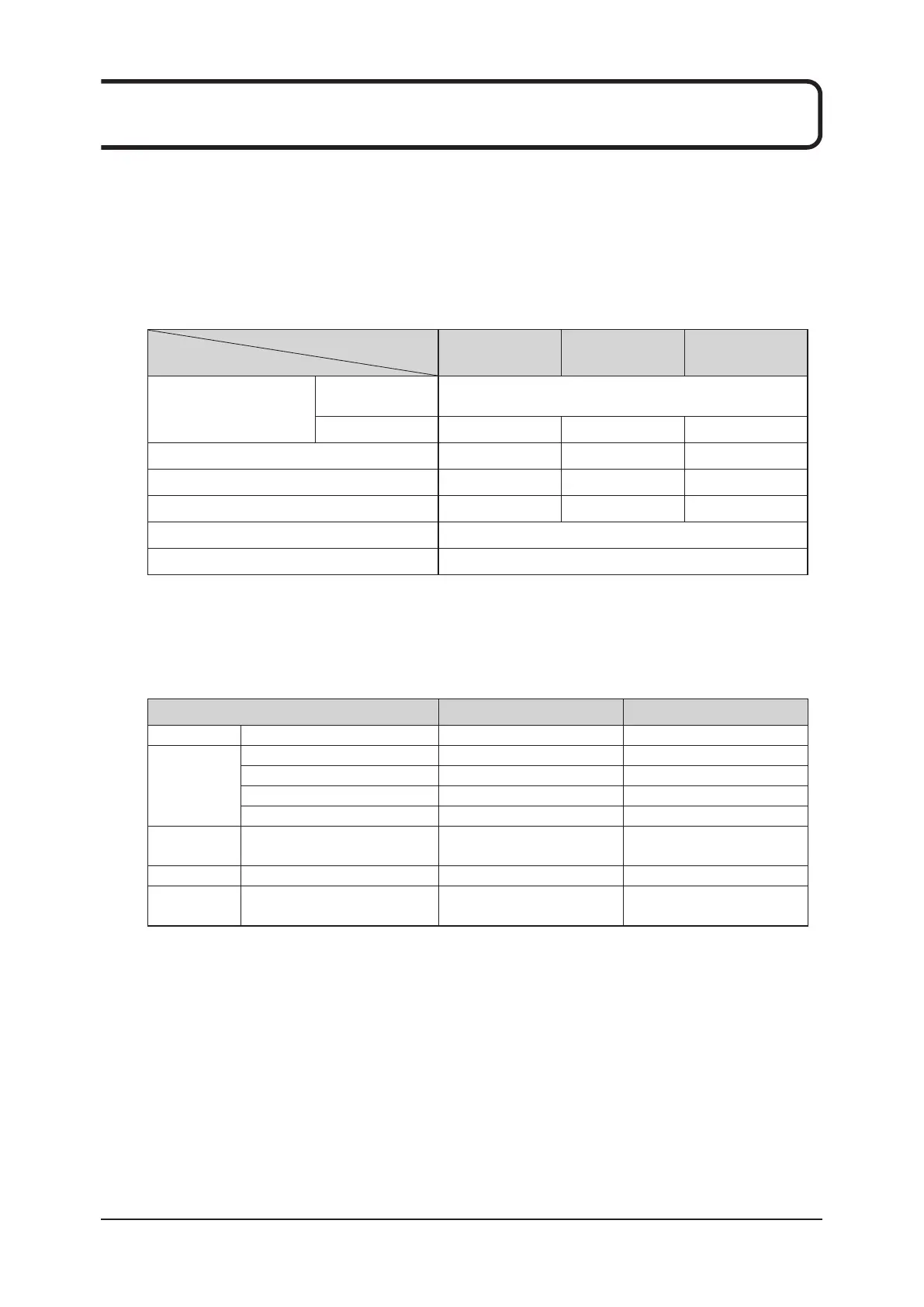

Maintenance and Items to be Checked by Users

Maintenance and items to be checked by users are as follows: Use the maintenance period as a guide.

Perform maintenance as needed depending on usage environment.

Maintenance Period

Description of Maintenance Work

Weekly Quarterly Semiannually

Printing QC patterns and

checking QC pattern results

When setting a

reference value

Three times in a row

In normal times ●

Cleaning film ejection tray ●

Cleaning supply tray ●

Cleaning air intakes/outlets ●

Changing deodorant filter Every 10,000 prints or every two years

Cleaning the Cleaning Roller Every 2,000 prints (mammography media users)

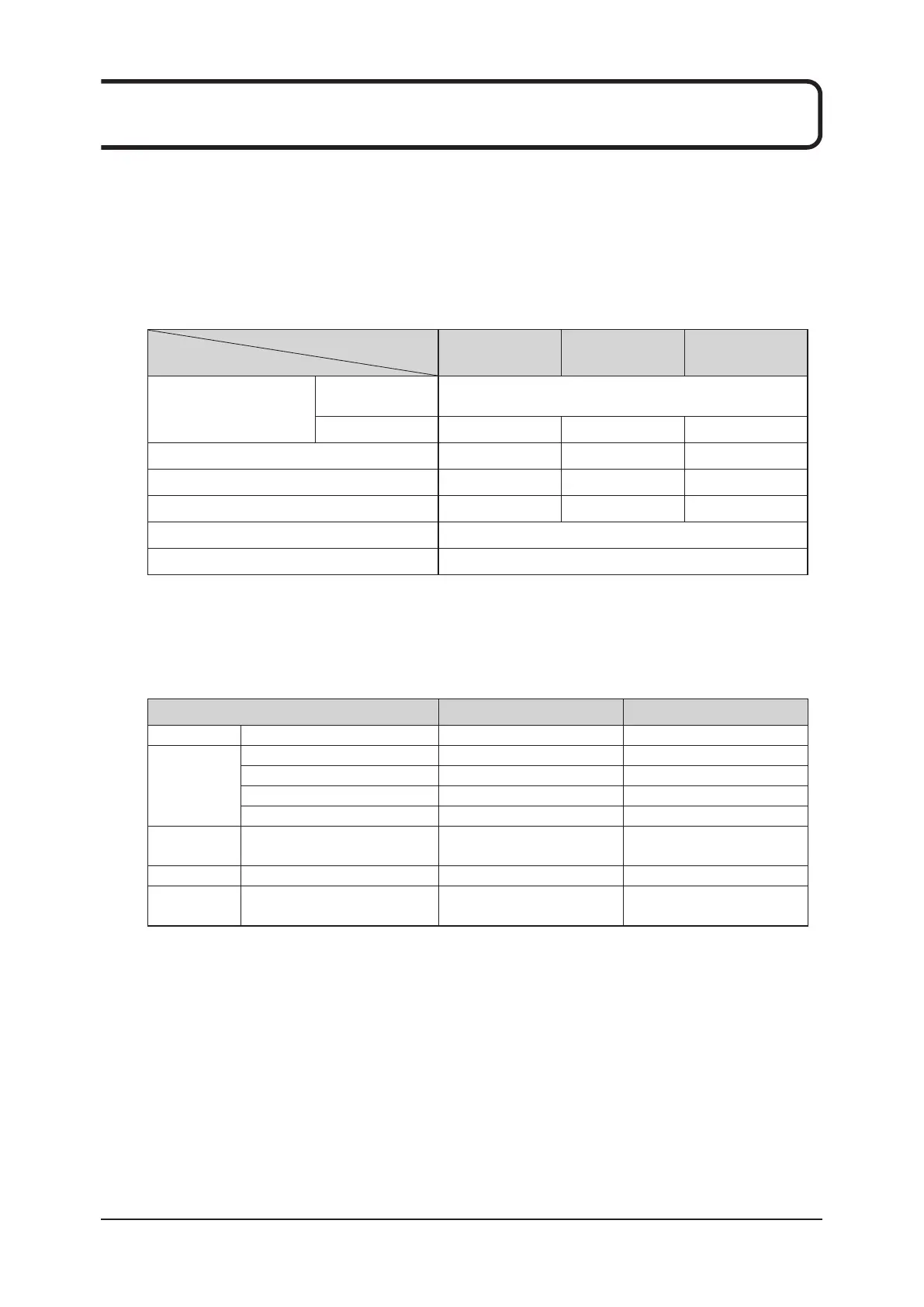

Maintenance and Items to be Checked by Service Personnel

Other major maintenance and items to be checked are as follows. These are included in the mainte-

nance contract. For performance of maintenance, contact Konica Minolta technical representatives.

Maintenance Parts Description Maintenance Period

Supply unit Pickup roller Replacement Every 50,000 prints

Heat process

unit

Opposed rollers (several sets) Replacement Every 50,000 prints

Opposed rollers Wiping with alcohol Every 50,000 prints

Cleaning guide Wiping with alcohol Every 50,000 prints

Heat development drive unit

Replacement Every 200,000 prints

Sub-scanning

unit

Sub-scanning belt

Replacement Every 200,000 prints

Control box Air intake filter Removing dust Every 50,000 prints

Power supply

unit

Air intake filter Removing dust Every 50,000 prints

*Overseas machines equipped with a transformer have filters and thus need cleaning.

Loading...

Loading...