4-1 Troubleshooting

4-1-2 FINS Command and System File Error Messages

93

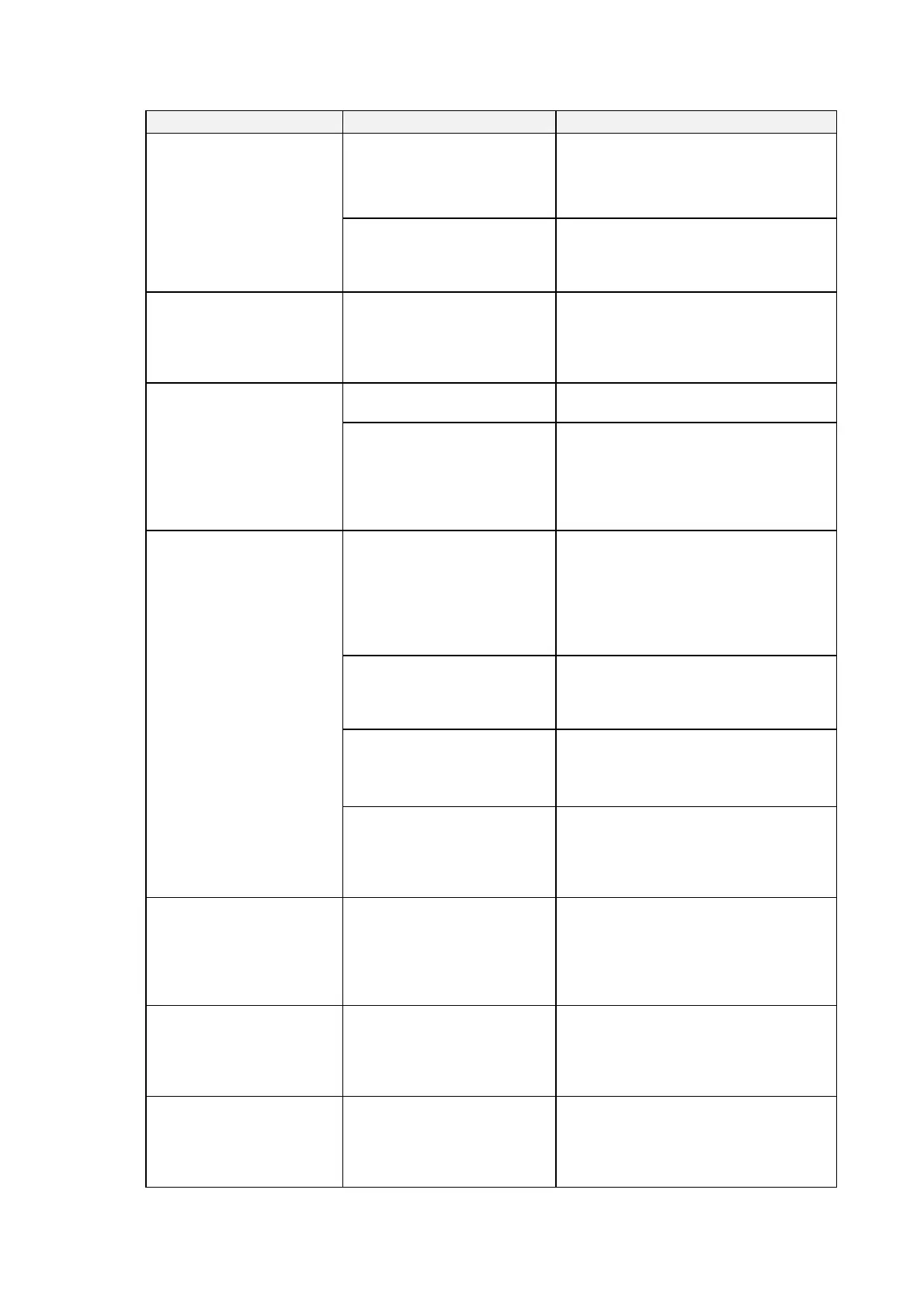

Message Probable cause Countermeasure

Data corrupted by noise, FINS

command receiving error

occurred.

Perform one of the following operations.

• Press the Operat Screen Button to exit

the Ladder Monitor.

• Press the Continue Button to reset

communications.

Time-our error by the following

cases: Corrupted data by noise.

Transmit error by the host.

MRES=XX, SRES=XX

An attempt was made to read or

search a program section while

UM read protection was set at the

host.

When reading a program section from the

Ladder Program, use the CX-Programmer to

clear the UM read protection at the host.

Monitoring address is incorrect.

It deletes all subscription of the

I/O monitor.

Monitoring address is incorrect.

Invalid I/O address of the

connecting PLC exists in the

ladder program section or I/O

monitor.

Press the

OK

Button to add the address for

multiple I/O monitoring.

Address changed the present

value cannot be written.

Press the

OK

Button to end the process.

Selected address type is read

only. Check and re-enter the

address.

Alloc.Host: XXXX

Alloc.Addr.: XXXX

MRES=XX, SRES=XX

A value such as an address was

changed for a host with FINS write

protection via the network

enabled.

If writing from the Ladder Monitor is permitted,

execute Nodes Excluded from Write

Protection in the CX-Programmer’s PLC

Setup. When connecting with a 1:N NT Link,

set the PT’s NT Link unit number + 1 as the

node address.

Disconnection of the

communications cable of

CS-series communications

service stopped (e.g., because

power was turned OFF), causing

FINS command reception time-out

error.

Check the communications cable and perform

one of the following operations.

1. Press the

Operat Screen

Button to exit the

Ladder Monitor.

2. Press the

Continue

Button to reset

communications.

Communications configuration,

such as PLC:PT= 1:N (8 max.)

high traffic is set on the

communications line.

Change the number for retry counts in the

system menu of the PT. (Default is 5 times.)

Cannot finish the search because

of conditions (program contains

100 Ksteps or more) that require

time to search instructions.

Increase the communications timeout monitor

time for searches in the Search Timeout

Watch Time Setting.

Time-out error by the following

cases:

Disconnection of the cable.

Stopped host.

MRES=XX, SRES=XX

Do you return it to the operation

screen?

When connected to the PLC using

a 1:N NT Link, the Maximum Unit

No. in NT Link/Serial PLC Link

Mode is set to 0 in the PLC Setup

at the PLC.

Set the Maximum Unit No. in NT Link/Serial

PLC Link Mode to 1 or higher.

Other peripheral tool is

accessing. Send commands

after success is permitted.

Alloc.Host: XXXX

Alloc.Addr.: XXXX

MRES=XX, SRES=XX

Other Support Software (e.g.,

CX-Programmer) is accessing the

same PLC.

Press the

OK

Button to end the process.

Perform the same process, again after

completing access from other Support

Software.

Cannot clear error.

MRES=XX, SRES=XX

The cause of the error is not

cleared when canceling the error.

Clear All Err can only be executed

when the PLC is in PROGRAM

mode but another mode is not set.

Press the

OK

Button to close the dialog box.

Then, clear the errors, again. Change the PLC

to PROGRAM mode before clearing all errors.

Cannot connect to this PLC

model.

Model code=XX

It returns it to the operation

screen.

Unsupported PLC is connected. Check the connected PLC and restart the

Ladder Monitor. SYSMAC CS/CJ-series PLCs

can be connected.