3.16

Engine/Cooling/Exhaust

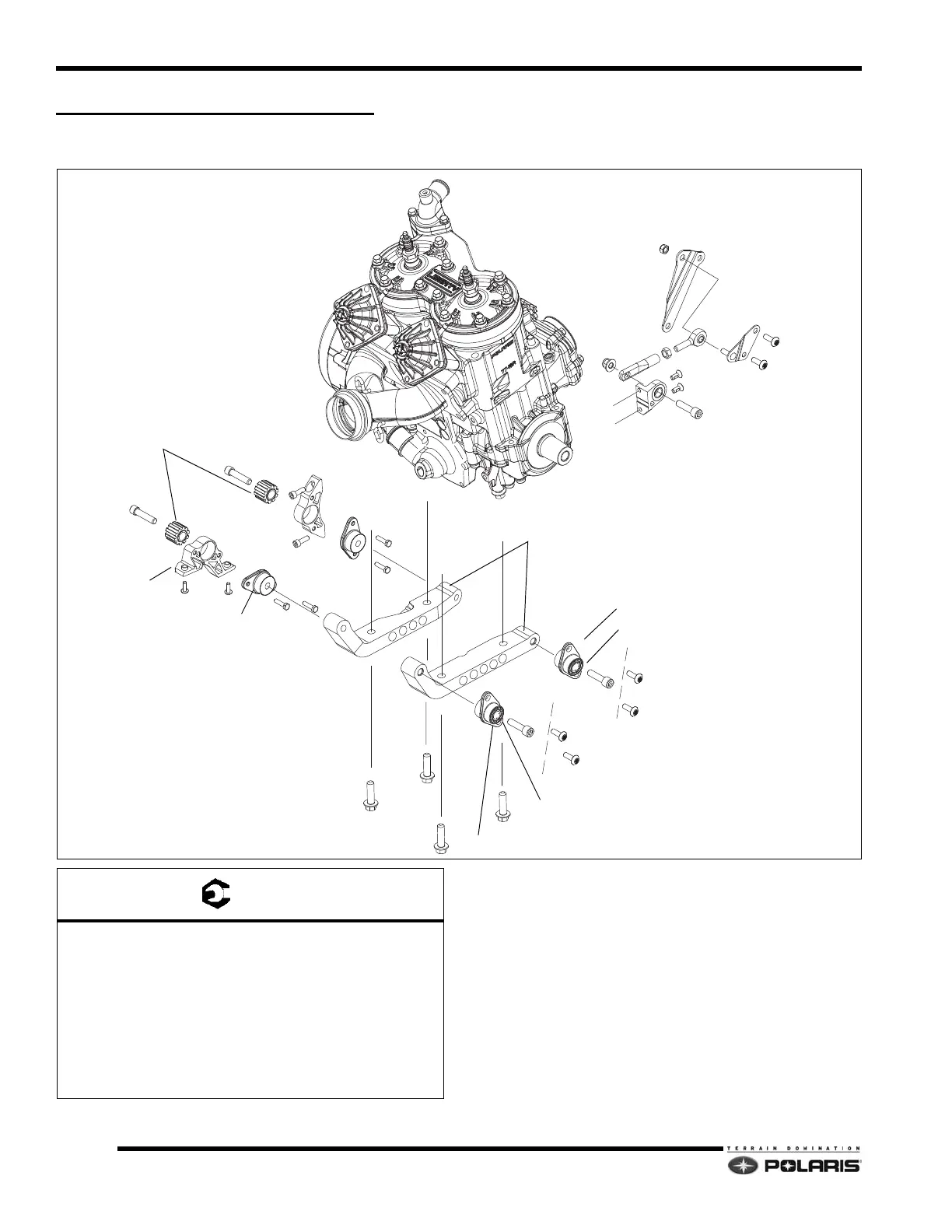

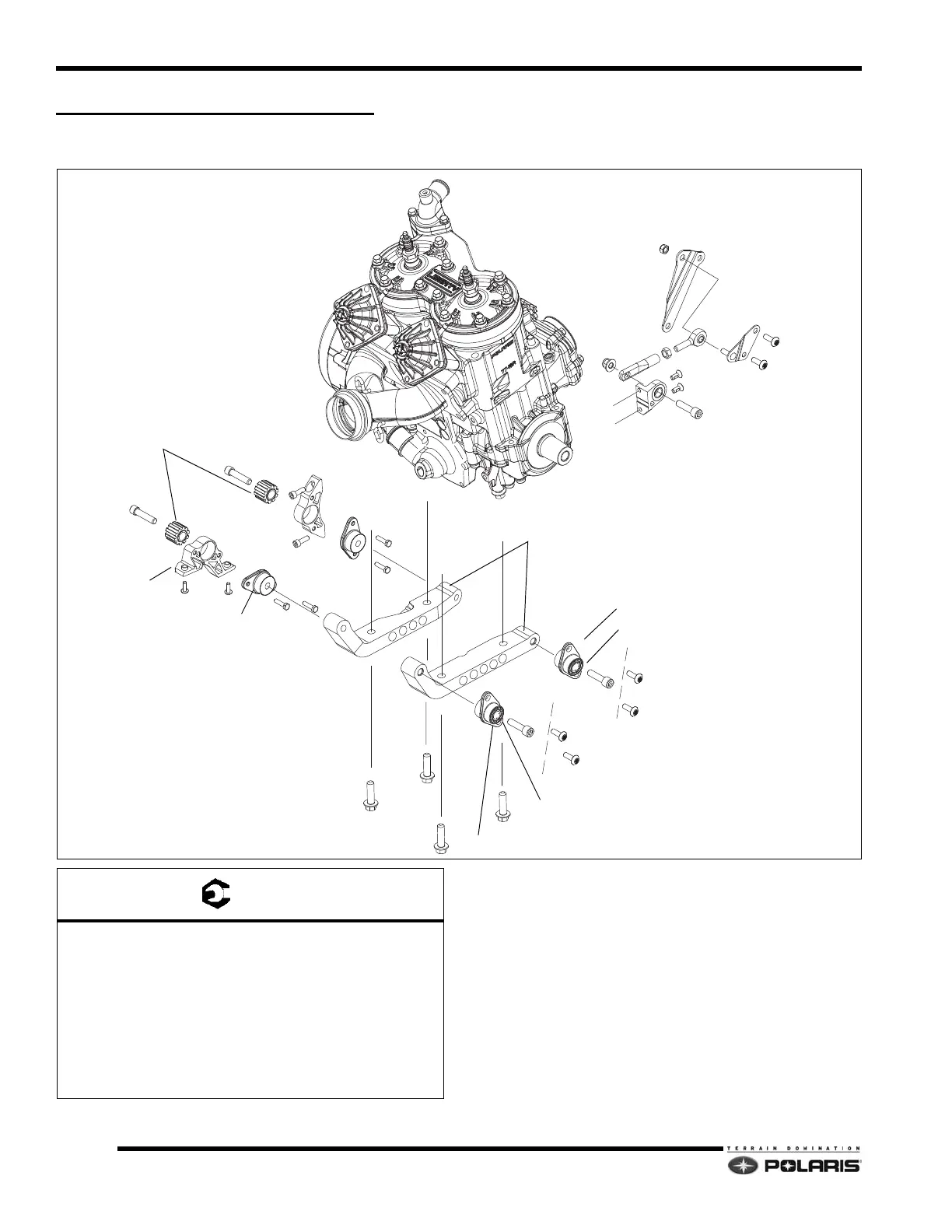

ENGINE MOUNTING SYSTEMS

2010 600 Engine Mounting

Assembly Notes:

• ENGINE MOUNT BOLTS-Note two torque values

for screw

s. Always clean engine mount threads

with compressed air or M10x1.5 tap before

installing screw(s). Apply Loctite® 242™ when

using original screw.

• To prevent the engine mount screws from catching

on

the radial inserts, spray the inserts with rubber

lubricant or isopropyl before installing engine

mount fasteners.

• Replace lock nuts with new parts when removed.

• Torque link length (center-to-center) = 3.33"

(8

4.63mm)

ENGINE ASSEMBLY

ENGINE MOUNTS

C

A

A

A

A

RADIAL INSERT (SMALL)

RADIAL INSERT (SMALL)

MOUNT W/CLINCH NUT

MOUNT W/CLINCH NUT

MOUNT

MOUNT

RADIAL INSERT (LARGE)

MOUNT BRACKET

MOUNT BRACKET

TORQUE LINK MOUNT

TORQUE LINK

TORQUE LINK OUTER

BRACKET

TORQUE LINK INNER

BRACKET

B

B

B

B

C

C

C

C

B

A

C

D

E

F

F

F

NOTE: SEE ENGINE MOUNT BOLT SERVICE REPLACEMENT KIT

A =

DK. GREEN-M10x1.5x45 (8.8) = 30 ft-lbs (41 Nm)

SILVER/GRY-M10x1.5x50 (12.9) = 35 ft-lbs (48 Nm)

B = 9 ft-lbs (12 Nm)

C = 26 ft-lbs (35 Nm)

D = 18 ft-lbs (24 Nm)

E = 12.5 ft-lbs (17 Nm)

F = 30 ft-lbs (41 Nm) Apply Loctite® 242™ to

th

reads.

Loading...

Loading...